Guide block for preventing linear displacement blocking of electromechanical actuator

An electromechanical actuator and linear displacement technology, which is applied in the field of guide blocks, can solve the problems of large rolling friction space requirements, loss of function of electromechanical actuators, and difficult processing, etc., to achieve heavy weight, difficult processing, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

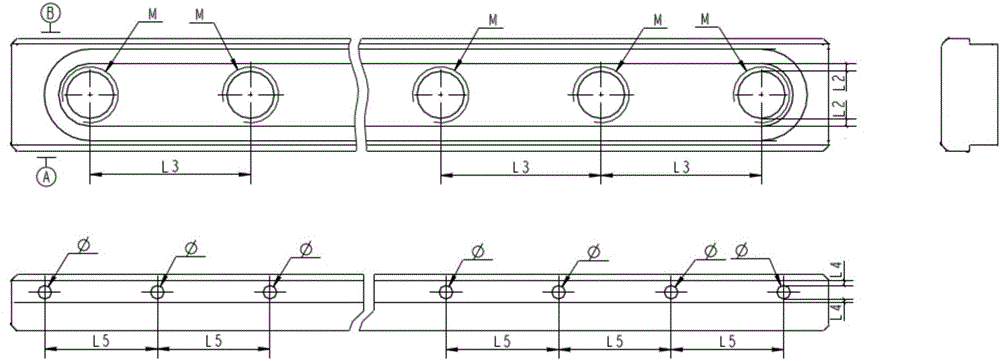

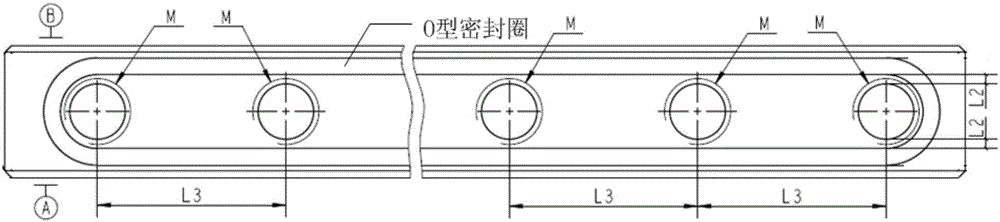

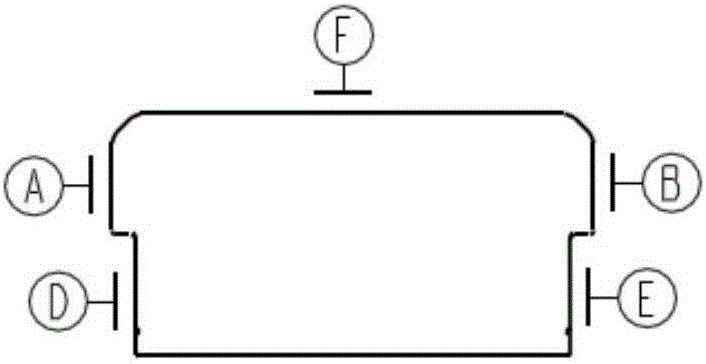

[0027] In the following, the guide block of the present invention will be described from several aspects with reference to the accompanying drawings. details as follows:

[0028] (1) Design the cross section of the guide block as T-shaped (such as figure 1 , 3 (Shown) to avoid direct collisions with the sharp edges and sharp corners of the lead screw nut guide groove, and prevent the lead screw nut guide groove from colliding with the guide block from generating extra objects and jamming and seizure;

[0029] After repeated, many times, a large number of experiments to summarize: such as Figure 5 As shown, (1) The narrow side of the T-shaped guide block should be smaller than the wide side, and L8 is (0.6~2)mm to determine the width as the best state, which will neither touch sharp corners nor affect the strength. (2) The narrow side should avoid the sharp angle L6=(0.35~0.75)mm to determine the most suitable height.

[0030] The “collision” mentioned above is not an exaggeration. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com