Novel double-sided meshing double-arc bevel gear nutation reducer and working method thereof

A double arc, bevel gear technology, applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problems of overlapping tooth profile interference, difficult to transmit large torque, difficult to decelerate, etc., to achieve good social benefits and economic benefits, improved stability and transmission accuracy, and reduced vibration and shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

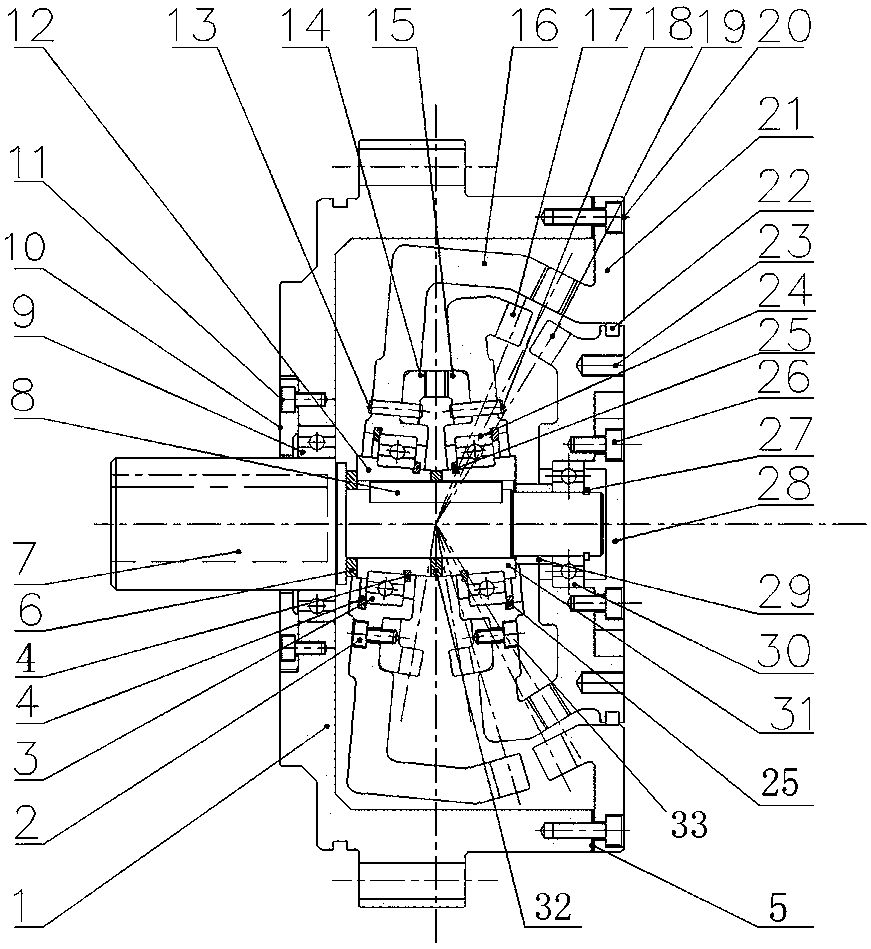

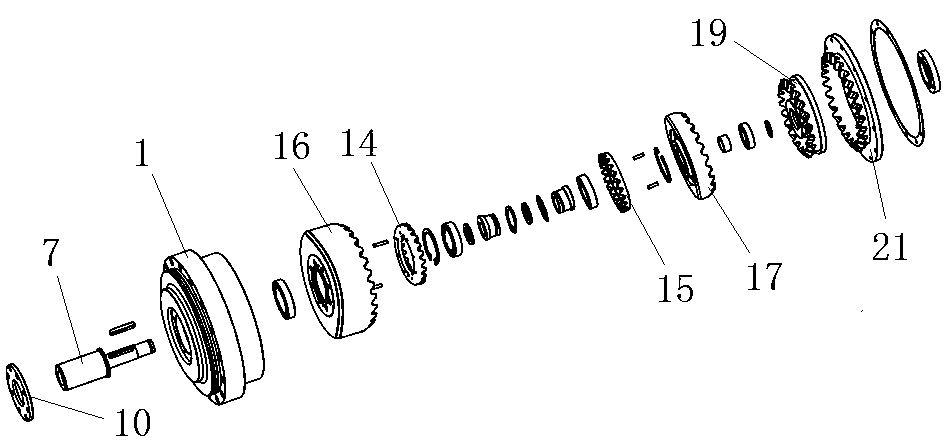

[0028] In order to explain the present invention more clearly, the present invention will be further described below in conjunction with the drawings and embodiments. Obviously, the drawings listed below are only some specific embodiments of the present invention.

[0029] Such as Figure 1~6 As shown, the present invention is a new type of double-sided meshing double-arc bevel gear nutation reducer, including a box body 1 and an input shaft 7 pierced in the middle of one side of the box body 1, and the input shaft 7 is located in the box body 1 The first nutating sleeve 12 and the second nutating sleeve 31 set opposite to each other are sleeved on the shaft section of the shaft section, and the first nutating sleeve 12 and the second nutating sleeve 31 are both connected to the input shaft 7 in transmission, the first chapter The first double-arc internal bevel gear 16 is connected with the first double-arc internal bevel gear 16 via the first bearing 3 on the moving sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com