Hydraulic forming technology of tube blank of small-sized corrugated tube and forming die sheet special for tube blank of small-sized corrugated tube

A hydraulic forming and corrugated tube technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as the length of expansion, the inability to ensure the accuracy of tube blank forming, and the difficulty in achieving the ideal processing effect, so as to improve the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

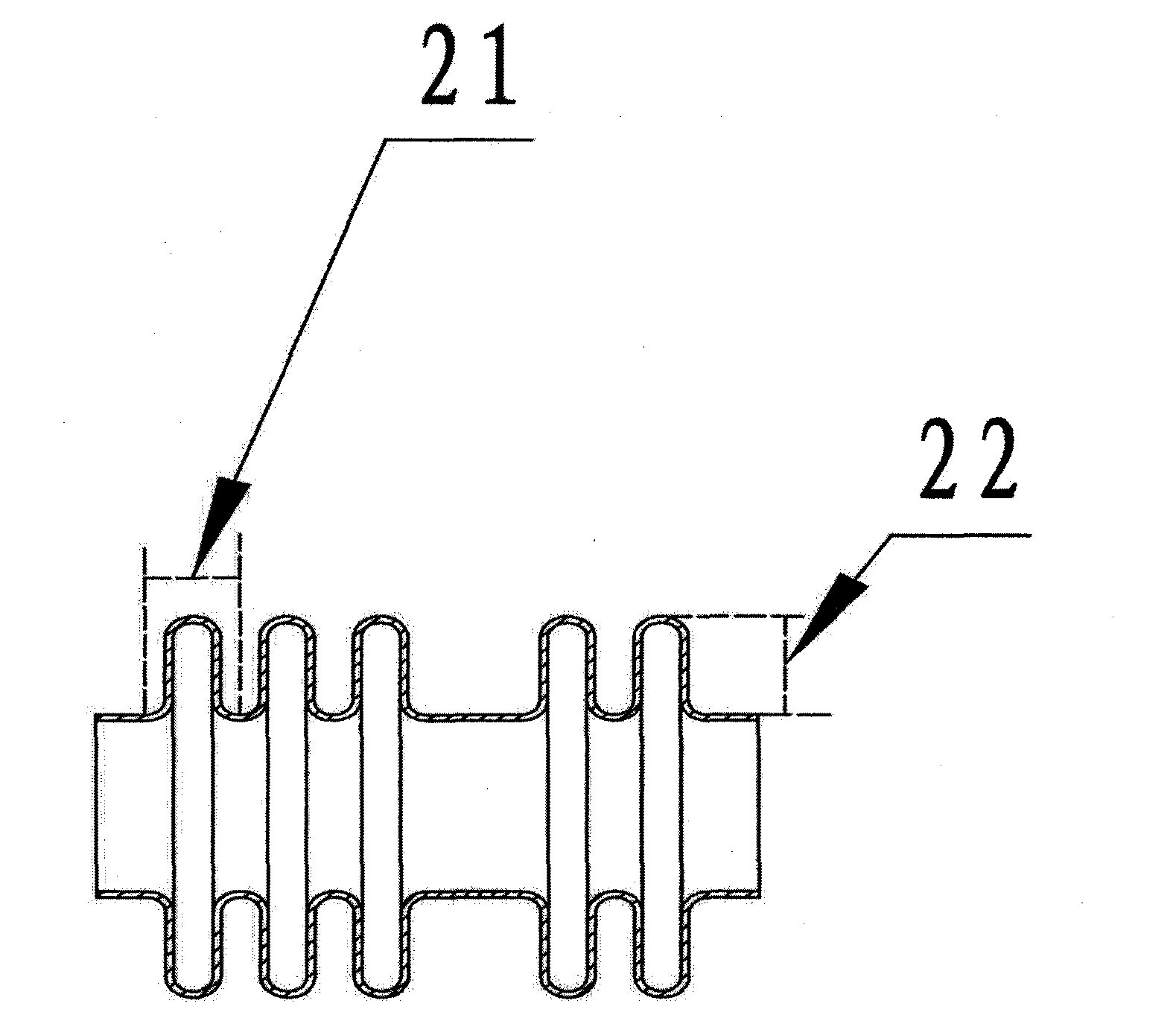

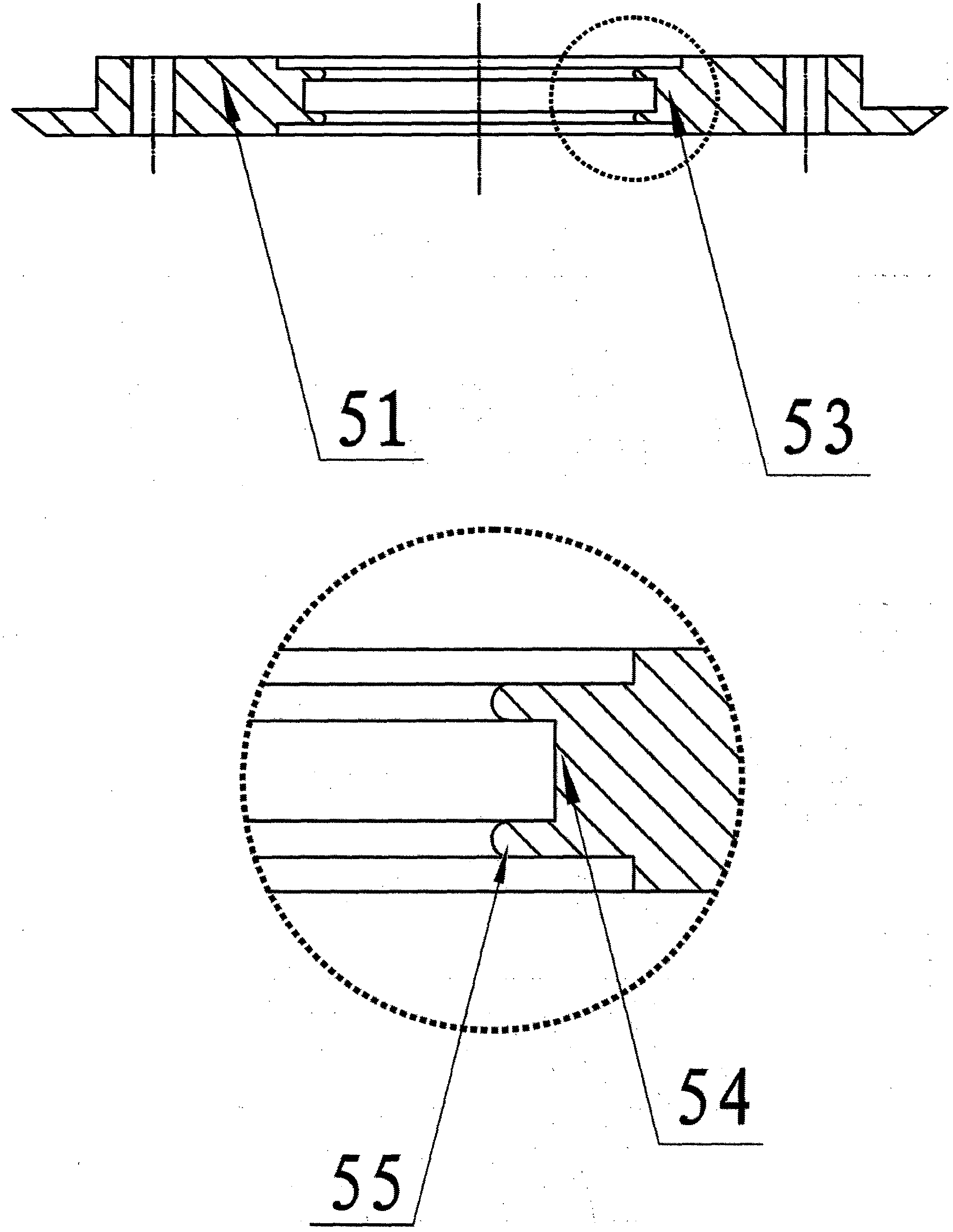

[0026] according to Figure 4 , Figure 5 As shown, a small stainless steel bellows hydroforming process with an inner diameter of 51 mm, a wave depth of 1.5 mm, and a single wave expansion length of 2.5 mm is as follows:

[0027] 1) Clean the workbench of the molding press, clean the molding mold with gasoline and install it. The installation sequence from top to bottom is upper sealing cover 1, 11mm thick molding pad 3, molding die 5, 11mm thick Form pad 3 and lower sealing cover 7. Wherein the molding die sheet 5 is assembled by inner ring 51 and outer ring 52;

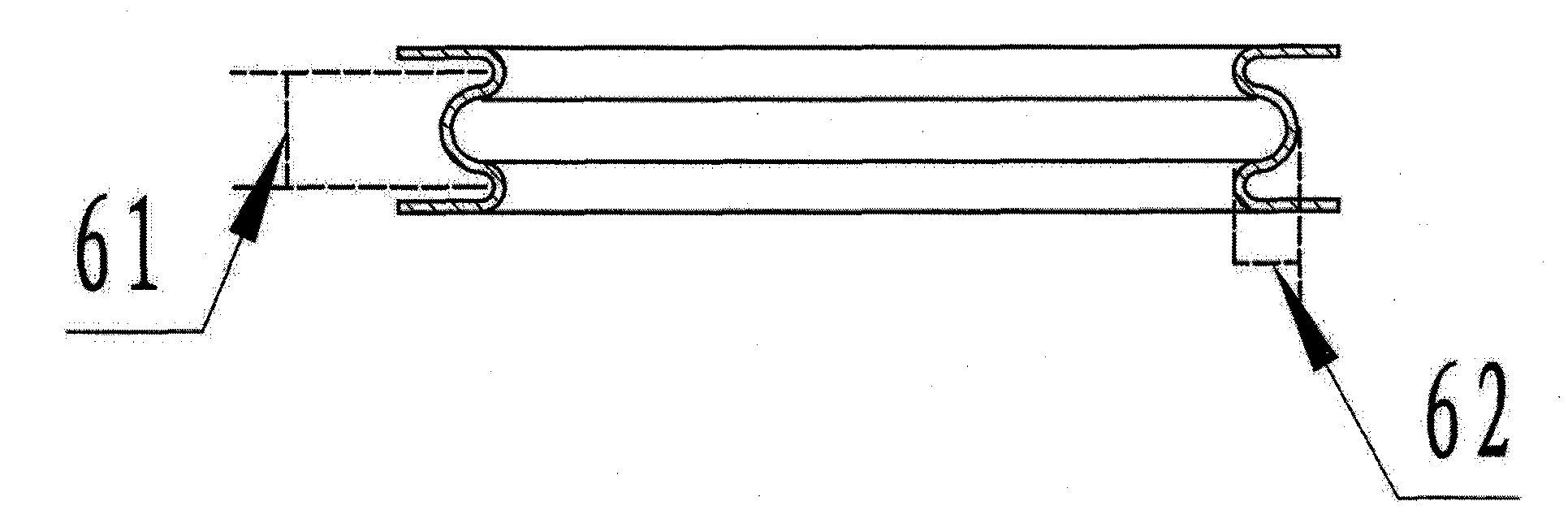

[0028] 2) Put the 0.25mm thick SUS304 stainless steel corrugated pipe blank 6 into the forming mold, and seal the mold;

[0029] 3) Press the upper sealing cover 1 and the lower sealing cover 7 so that a completely sealed airtight space can be formed between the upper sealing cover 1, the bellows tube blank 6 and the lower sealing cover 7, and inject hydraulic oil 8 into the unformed bellows In the tube blank 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com