High-silicon-content silicon-carbon negative electrode plate and preparation method thereof

A negative pole piece, silicon carbon technology, applied in the direction of battery electrodes, electrode carriers/current collectors, electrical components, etc., can solve the problems of low electronic conductivity, poor cycle performance, and low potential for lithium extraction and extraction, and achieve improved specific capacity , solve the cost and process difficulty, and alleviate the effect of silicon negative electrode expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

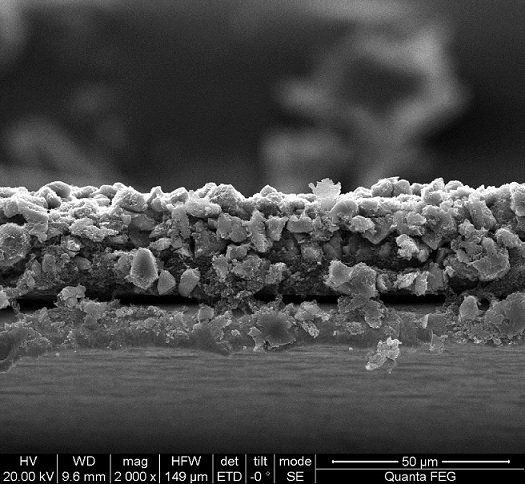

[0022] This embodiment also provides a method for preparing a silicon-carbon negative electrode sheet with a high silicon content, which is characterized in that it includes the following steps:

[0023] S1: Use a double planetary mixer to disperse and homogenize the carbon material and binder A in deionized water or N-methylpyrrolidone according to a certain ratio to obtain a carbon slurry; use an extrusion coating machine to apply the carbon slurry to the current collector Coating and drying on the carbon layer to obtain a pole piece coated with a carbon layer; the solid content of the carbon slurry is not specifically limited, preferably 20%-40%, if the solid content is too high or too low, the viscosity of the slurry will be unsuitable and difficult to apply;

[0024] S2: Use a double planetary mixer to disperse and homogenize the silicon particles, conductive agent and binder B in deionized water or N-methylpyrrolidone according to a certain proportion to obtain a silicon...

Embodiment 1

[0030] SiO silicon particles were selected, and the average particle diameter of the SiO particles in a fully charged state was measured to be 15 μm according to the above method. Use a double planetary mixer to disperse conductive carbon black SP and polyacrylic acid PAA in deionized water at a ratio of 98:2, with a solid content of 25%, and then use an extrusion coater to coat the slurry on copper foil And dry, after coating, the porosity measured by mercury porosimeter and BET specific surface area test method is 66%, and the coating thickness is 35 μm, which meets the requirements of fully charged particle size of silicon particles < thickness of carbon layer × porosity < silicon particles Fully charged state particle size × 2. Disperse and homogenize SiO silicon particles, single-wall carbon nanotube conductive agent SWCNT and polyacrylonitrile PAN binder in N-methylpyrrolidone solvent according to the ratio of 95:1.5:3.5, with a solid content of 45%, and then use extrusi...

Embodiment 2

[0033] Other steps are the same as in Example 1, the difference is that the SiO silicon particles in Example 1 are replaced by nano-silicon particles, and the average particle diameter of the nano-silicon particles in a fully charged state is 8 μm, and the conductive carbon black SP in Example 1 is replaced by Adult artificial graphite, the porosity after coating is 47%, and the coating thickness is 30μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com