Trivector hydrophone based on piezoelectric velocity sensor

A speed sensor and three-dimensional vector technology, applied in radio wave measurement systems, instruments, measurement devices, etc., can solve the problems of low free field voltage sensitivity, restricting the engineering application of vector hydrophones, etc., and achieve good cosine directivity and simple structure. , the effect of high channel sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

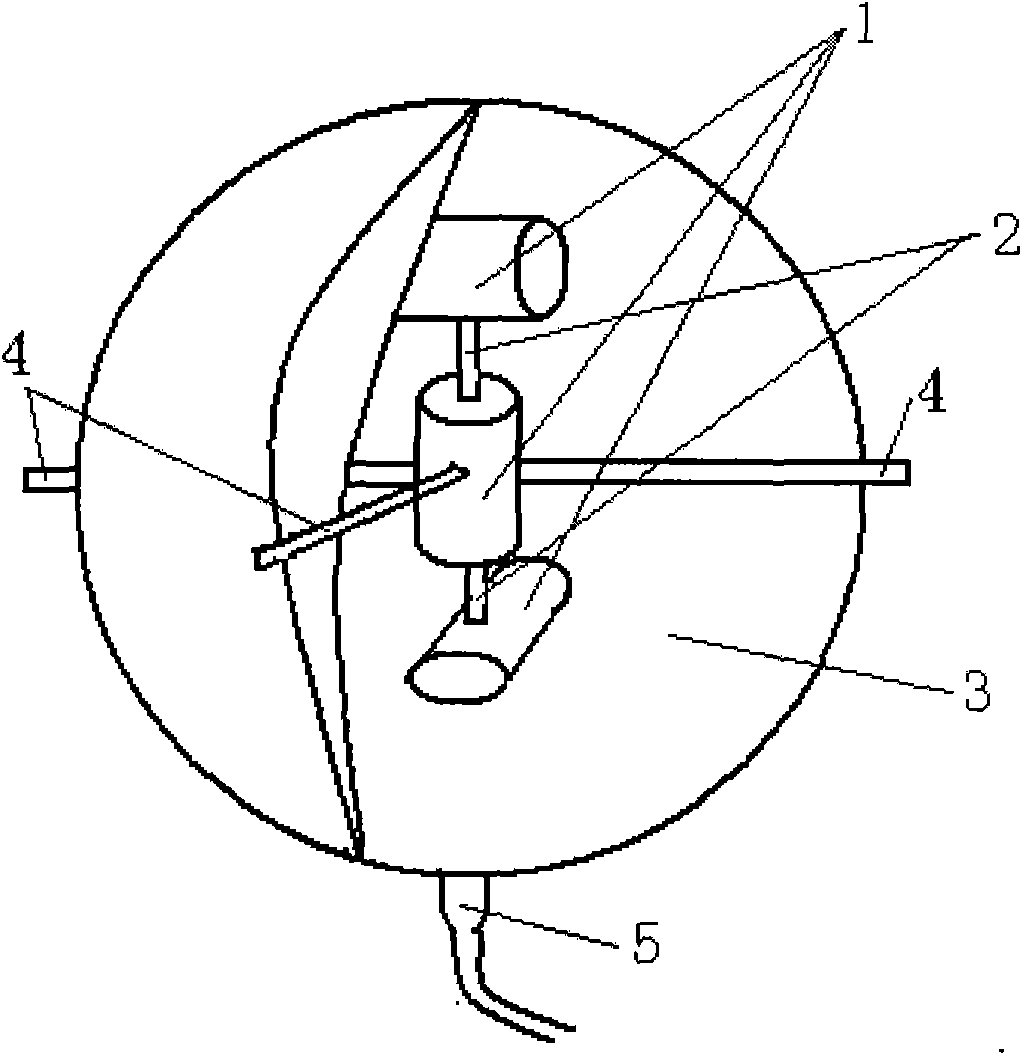

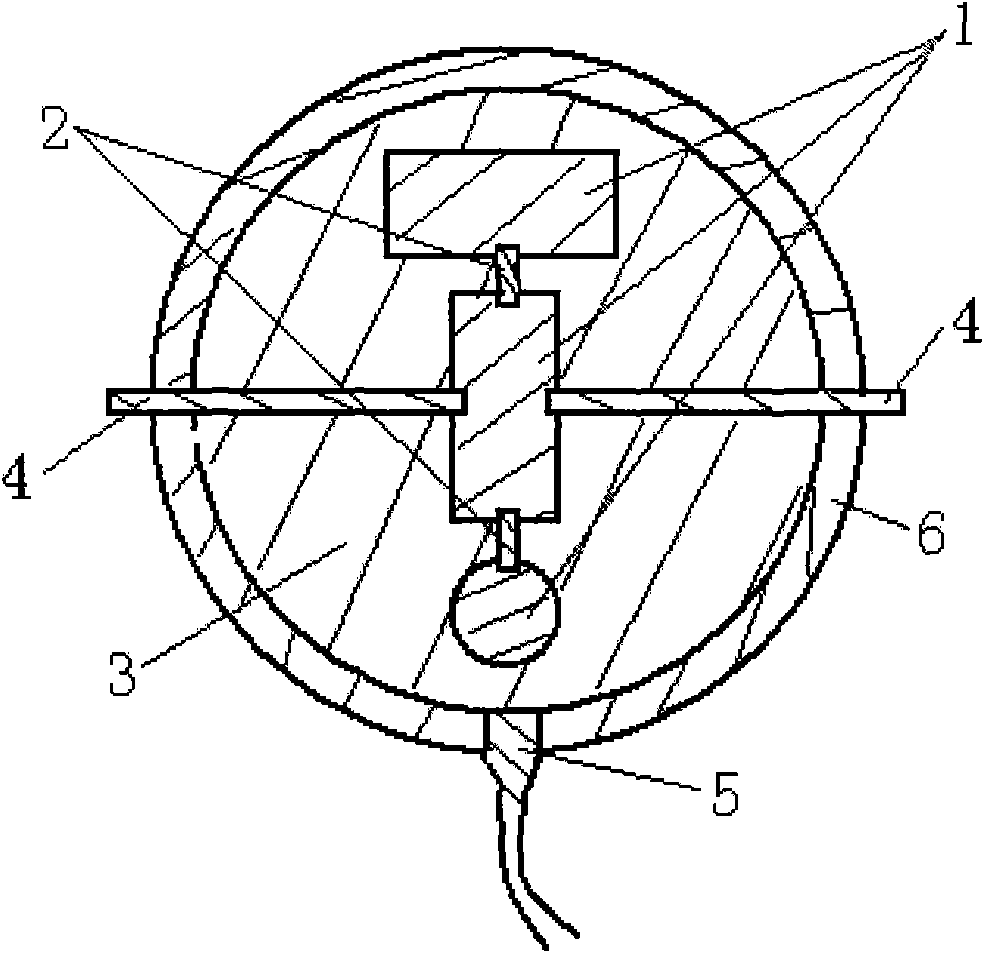

[0022] to combine figure 1 . The composition of the present invention includes a cable [5] with a multi-core output belt, four suspension rods [4], three piezoelectric speed sensors [1], connecting rods [2] and solid spheres [3]. Four suspension rods are evenly distributed on the outer surface of the sphere. Three piezoelectric speed sensors are respectively placed in sequence along the vertical direction, and their axial directions point to the three coordinate directions of X, Z and Y respectively.

[0023] The preparation method of the present invention is as follows: firstly, three piezoelectric speed sensors [1] are rigidly connected in the vertical direction by means of connecting rods [2], and then four suspension rods [4] are evenly fixed in the middle of the speed sensor [ 1], place the connected three speed sensors [1] with four suspension rods [4] in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com