Golf equipment formed from castable formulations with resiliency comparable to ionomer resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

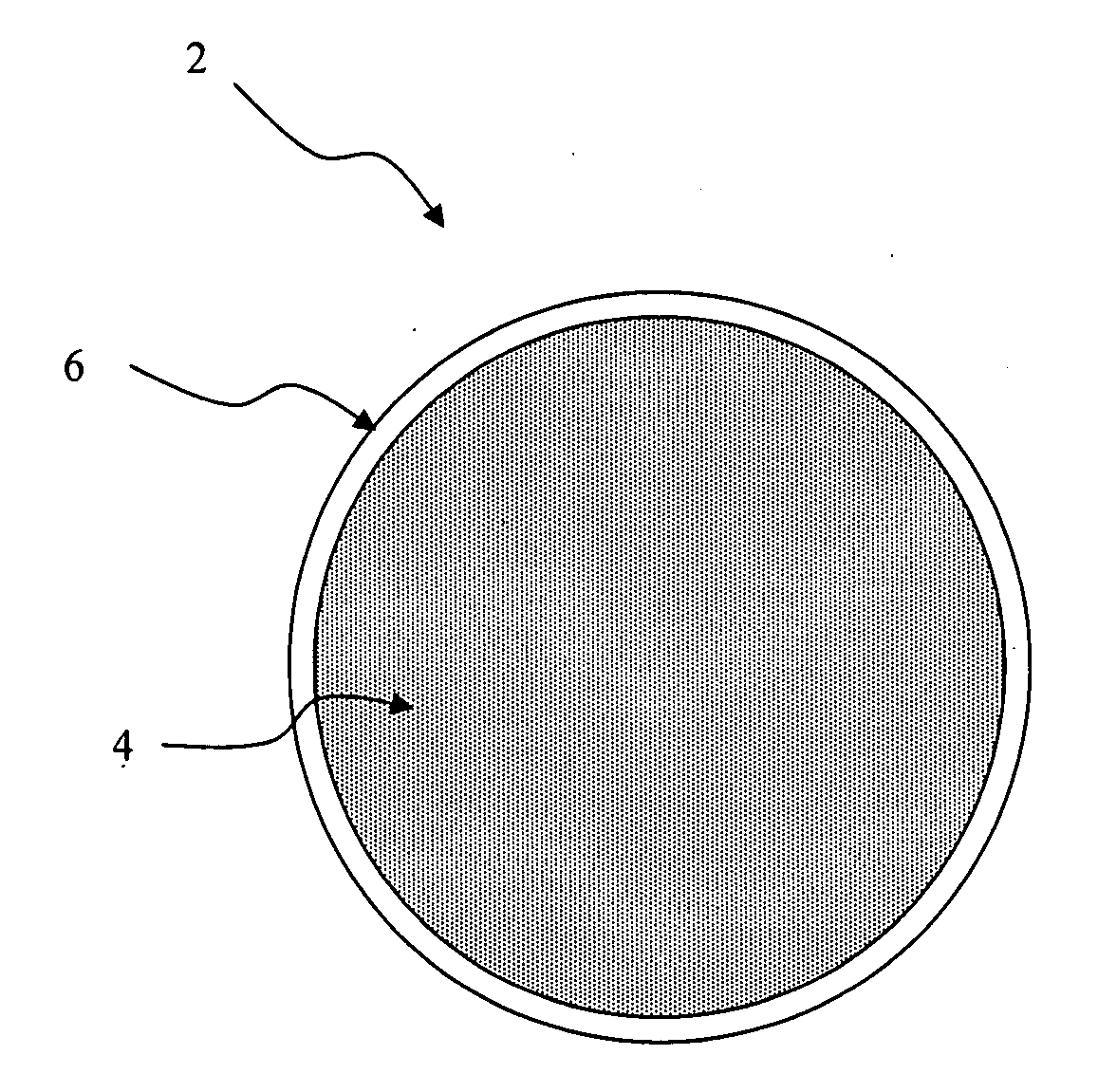

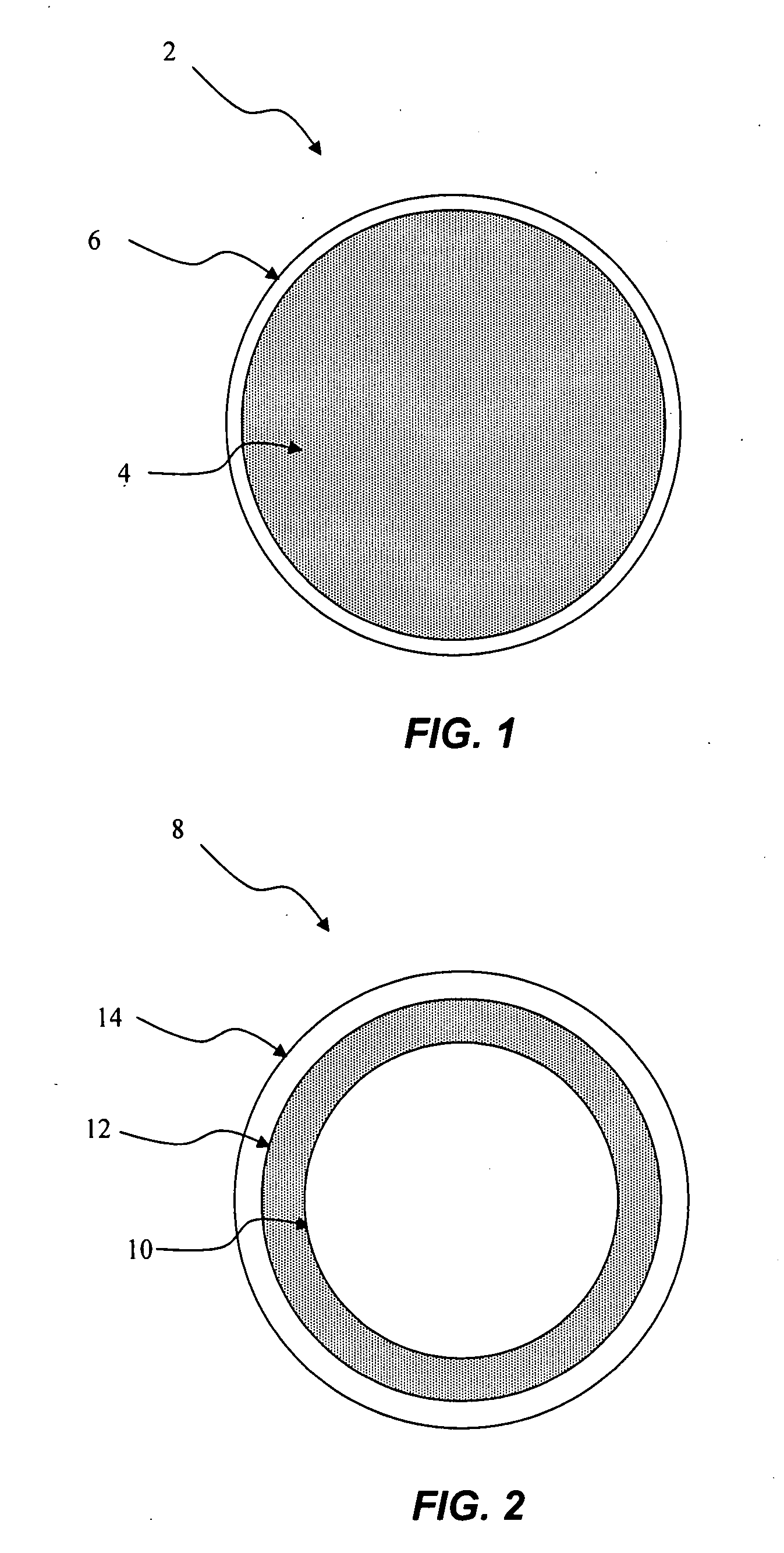

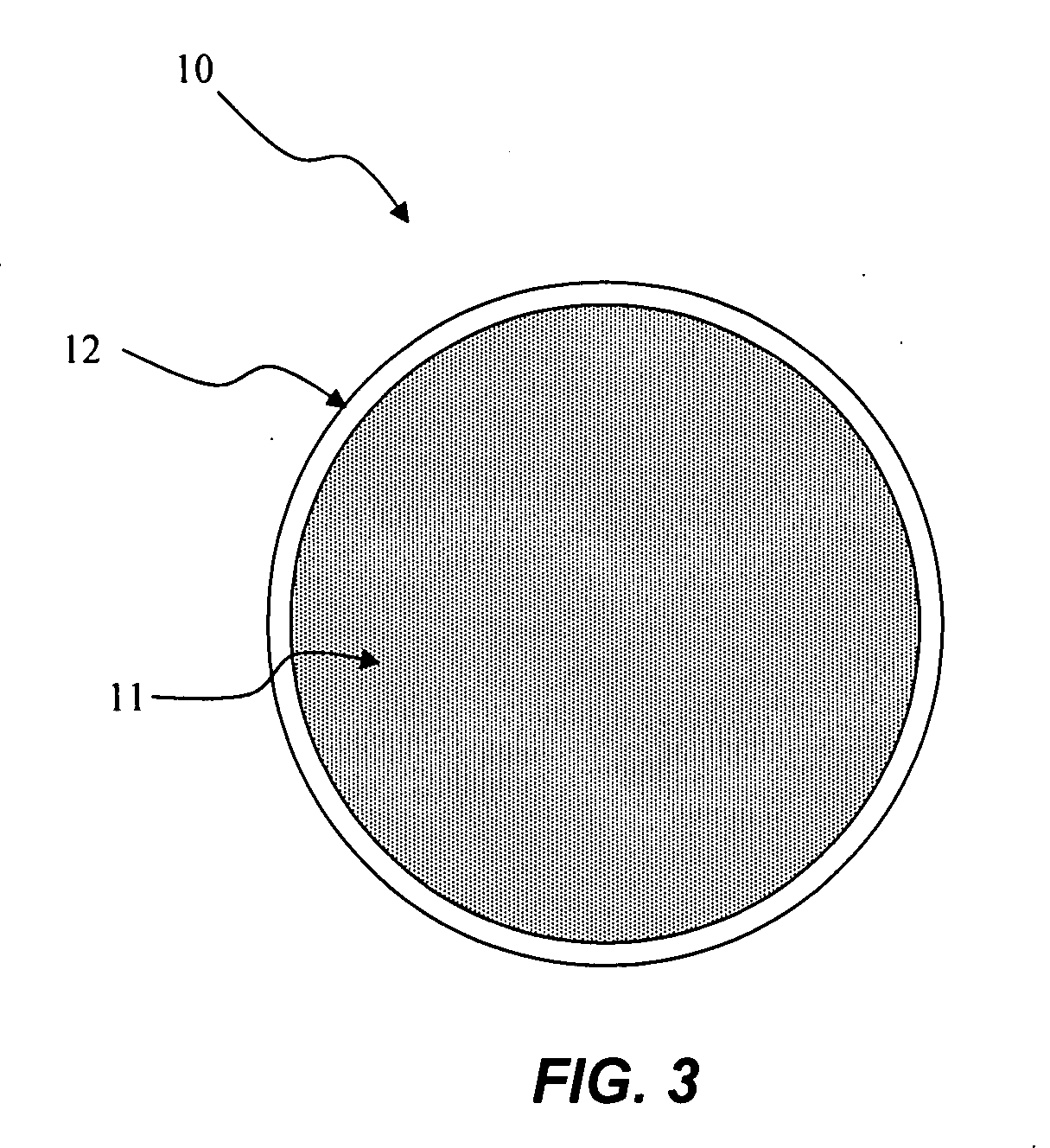

Image

Examples

example 1

Solid Sphere Formed with Composition of Invention

[0311]A solid sphere was formed with a composition of the invention (sample #1). As shown in Table 2, the compression and coefficient of restitution (COR) are higher than solid spheres formed with ionomeric materials. In particular, a composition was formed by reacting excess aliphatic polyisocyanate based on hexamethylene diisocyanate having NCO content of 24 percent (Desmodur® XP-2410, available from Bayer) with a secondary diamine having a molecular weight of 2050 (Jeffamine® XTJ-576, commercially available from Huntsman) to form a prepolymer having free NCO content of 14 percent. The prepolymer was then crosslinked with 3,3′-dimethyl-4,4′-bis(sec-butylamino)-dicyclohexylmethane (Clearlink® 3000, available from UOP) at a ratio of 1:0.95 prepolymer to curing agent. Comparison solid spheres were formed using the ionomeric materials found in the covers of various Titlelist golf balls, i.e., samples #2 and #3 are based on the cover mat...

example 2

Compositions of Invention

[0312]In addition to the formulation described above in Example 1, as shown in Table 3, compositions of the invention may be formed using variations of these components.

TABLE 3COMPOSITIONS OF THE INVENTIONComponent#1#2#3#4#5#6#7Isocyanate-ContainingSaturationAliphaticAliphaticAliphaticAliphaticAliphaticAromaticAromaticComponentBaseHDIHDIHDIHDIHDIMDIMDINCO Content 24 24 2420 ± 120 ± 131.5 ± 5 24Isocyanate-ReactiveType of2°2°2°2°2°2°2°ComponentamineBasePPGPPGPPGPPGPPGPPGPPGMolecular23043040002000400020004000WeightCuring Agent3,3′-dimethyl-4,4′-bis(sec-butylamino)-dicyclohexylmethane(ratio of 1:0.95 prepolymer to curing agent)

[0313]A catalyst may be added to any of the above formulations to modify the cure rate. For example, dibutyltin dilaurate may be added in an amount of about 0.005 to about 0.01 percent based on total resin solids.

[0314]As used herein, the term “about” is used in connection with one or more numbers or numerical ranges, should be understood ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com