Flavone-metal complex microsphere and preparation method and application thereof

A technology of metal complexation and microspheres, applied in the preparation of sugar derivatives, chemical instruments and methods, pharmaceutical formulations, etc., can solve problems that have not been reported before, achieve good biocompatibility, good acid resistance, and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

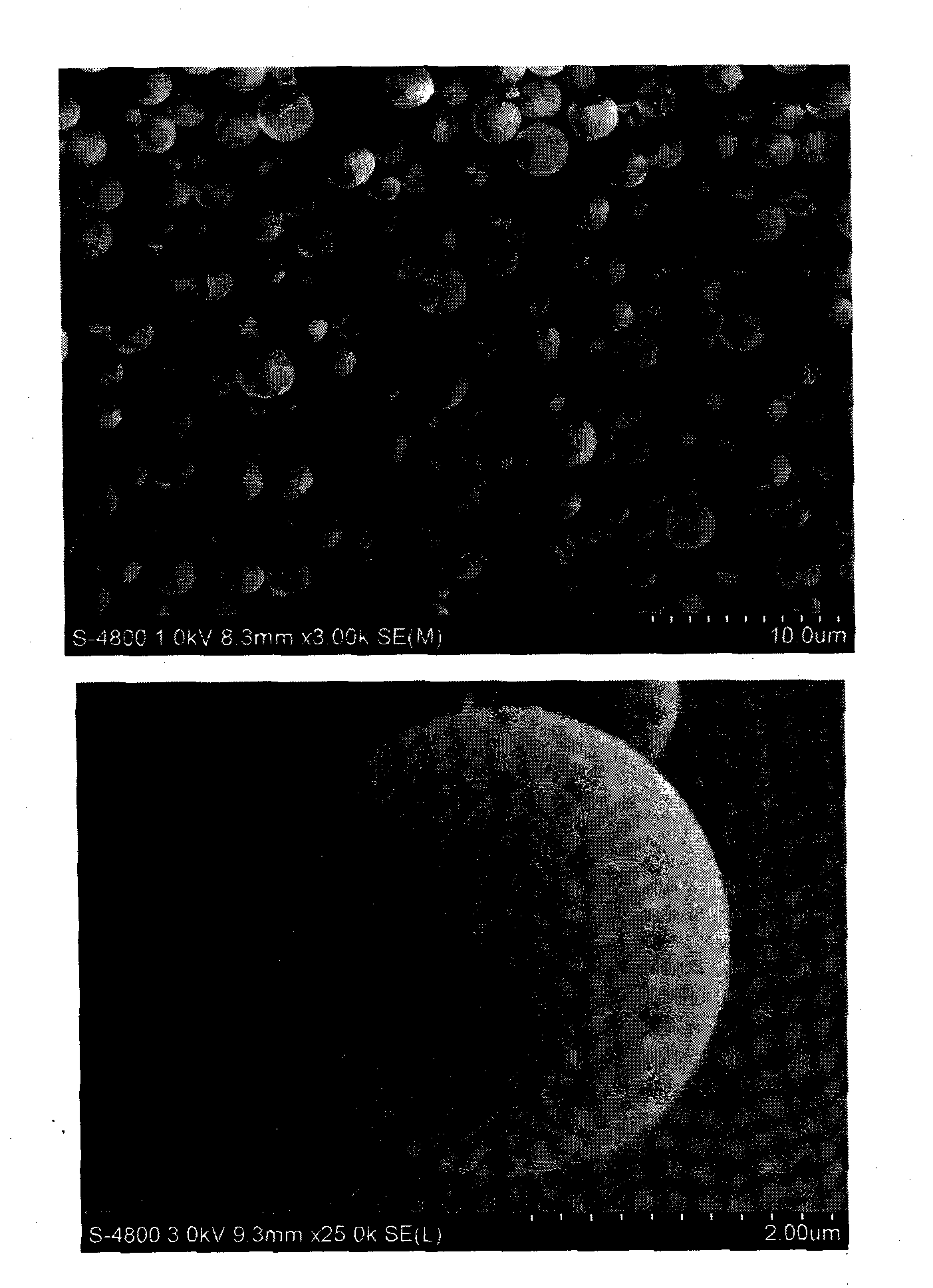

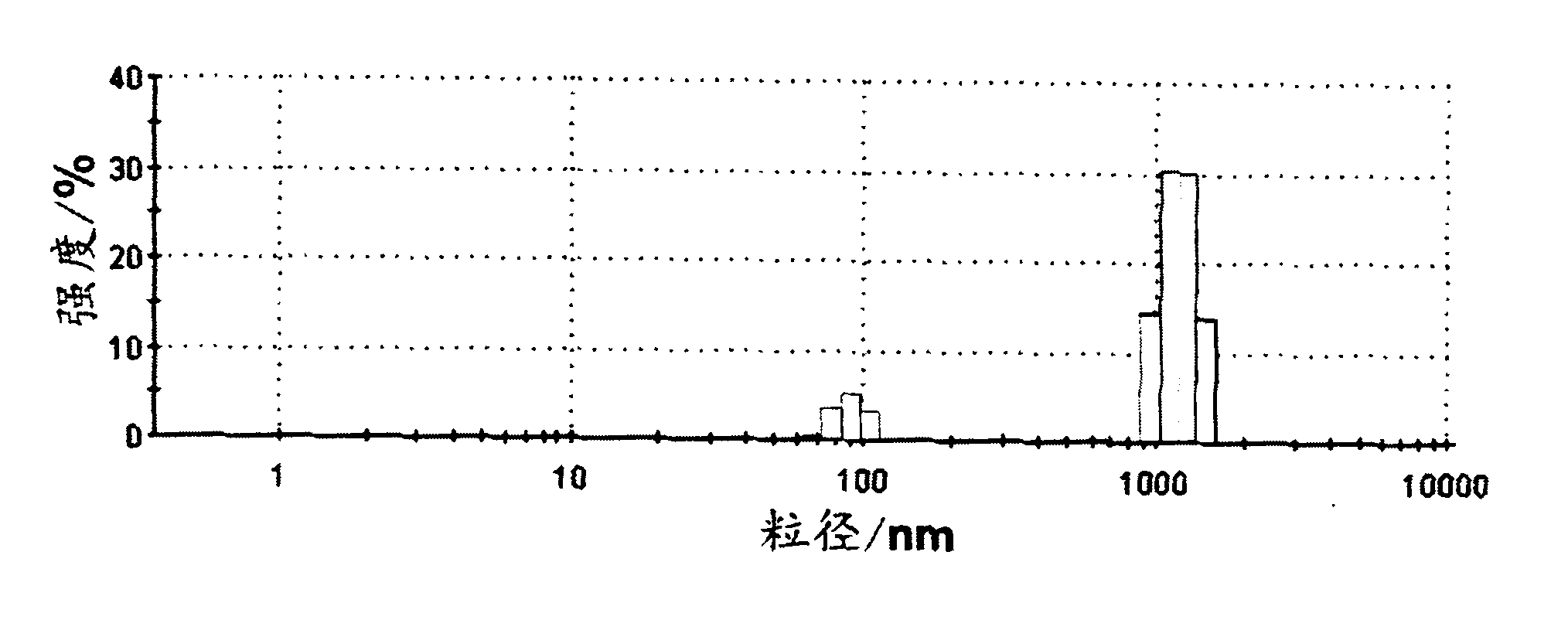

Image

Examples

Embodiment 1

[0059] In the present embodiment, flavone-metal complex solid microspheres are prepared, and the process steps are as follows:

[0060] (1) Preparation of flavonoids solution

[0061] Add 0.01g of rutin to a reaction vessel containing 21mL of deionized water at normal pressure and room temperature, and dissolve the rutin completely under stirring;

[0062] (2) Reaction synthesis

[0063] Add Ag in the rutin aqueous solution prepared in step (1) under stirring + AgNO at a concentration of 0.06mol / L 3 Aqueous solution 1.5mL, auxiliary agent ethylene glycol 0.05mL to form a reaction solution, then use NaOH aqueous solution with a concentration of 0.1mol / L and HCl with a concentration of 0.1mol / L to adjust the pH value of the reaction solution, when the pH value of the reaction solution is stabilized at 6 , heated to 60°C for 15 hours at constant temperature under normal pressure;

[0064] (3) Product collection and drying

[0065] After the reaction, the precipitate was coll...

Embodiment 2

[0068] In the present embodiment, flavone-metal complex solid microspheres are prepared, and the process steps are as follows:

[0069] (1) Preparation of flavonoids solution

[0070] Add 0.1 kg of tea polyphenols into a reaction vessel containing 7.8 L of deionized water at normal pressure and room temperature, and dissolve the tea polyphenols completely under stirring;

[0071] (2) Reaction synthesis

[0072] Add Sr to the tea polyphenol aqueous solution prepared in step (1) under stirring 2+ SrCl with a concentration of 0.6mol / L 2 Aqueous solution 2.0L, auxiliary agent ethylene glycol 0.2L to form a reaction solution, then adjust the pH value of the reaction solution with a concentration of 0.5mol / L ammonia solution and a concentration of 0.5mol / L HCl, when the pH value of the reaction solution is stable at 8 , heated to 60°C for 15 hours at constant temperature under normal pressure;

[0073] (3) Product collection and drying

[0074] After the reaction, collect the p...

Embodiment 3

[0077] In the present embodiment, flavone-metal complex solid microspheres are prepared, and the process steps are as follows:

[0078] (1) Preparation of flavonoids solution

[0079] Add 1.0 g of flavanols into a reaction vessel containing 120 mL of deionized water at normal pressure and room temperature, and dissolve the flavanols completely under stirring;

[0080] (2) Reaction synthesis

[0081] Add Mg to the flavanol aqueous solution prepared in step (1) under stirring 2+ Concentration of 0.3mol / L MgSO 4 ·H 2O aqueous solution 25mL, auxiliary agent ethylene glycol 5mL form reaction solution, then adjust the pH value of reaction solution with the ammonia solution of concentration 0.5mol / L and the HCl of concentration 0.5mol / L, after the pH value of reaction solution is stable at 8, Heating to 70°C for 13 hours at constant temperature under normal pressure;

[0082] (3) Product collection and drying

[0083] After the reaction, collect the precipitate by filtration, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com