Porous spherical electrospinning nozzle and spinning method thereof

An electrospinning, porous spherical technology, applied in the directions of electrospinning, textile and papermaking, filament/thread forming, etc., can solve the problems of single nanofiber membrane structure and uncontrollable fiber multi-level diameter distribution, and achieve simple technology. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

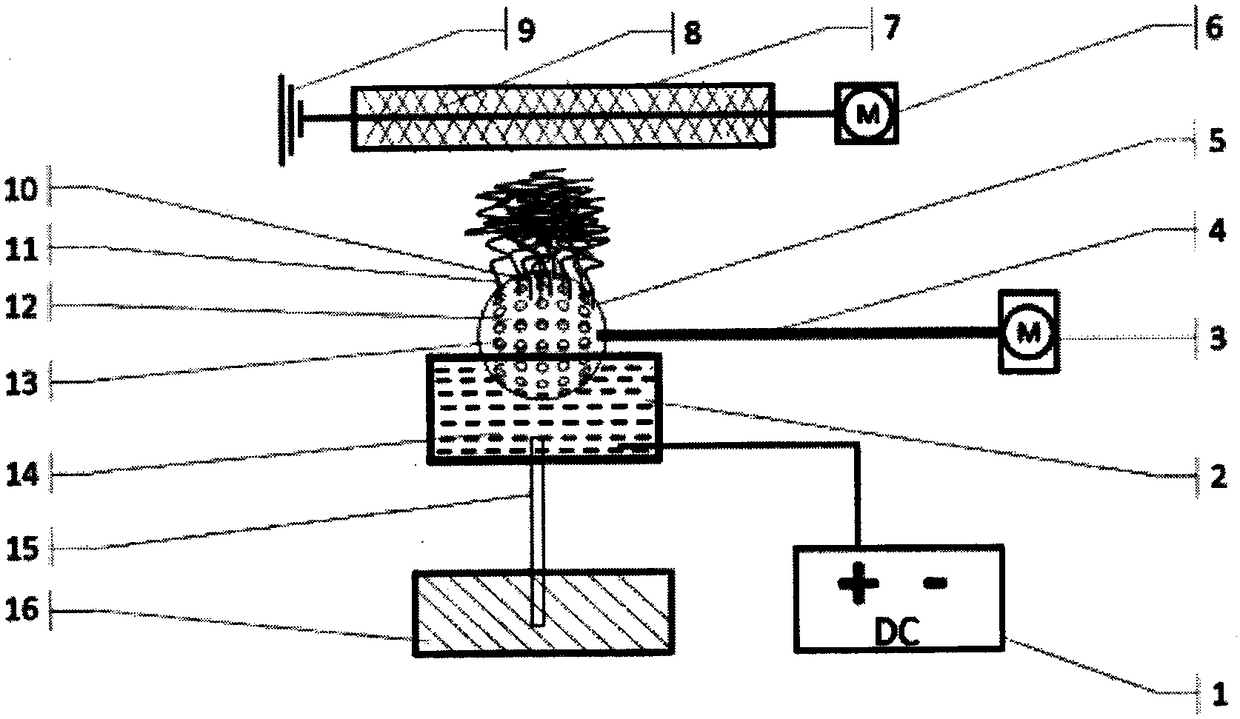

[0030] A method of electrospinning:

[0031] The spinning solution 14 uses a polymer solution prepared from polyacrylonitrile (PAN) and N-N dimethylformamide (DMF) to prepare nanofibers with controllable multi-level diameter distribution. The mass fraction of the prepared PAN polymer solution is 10%.

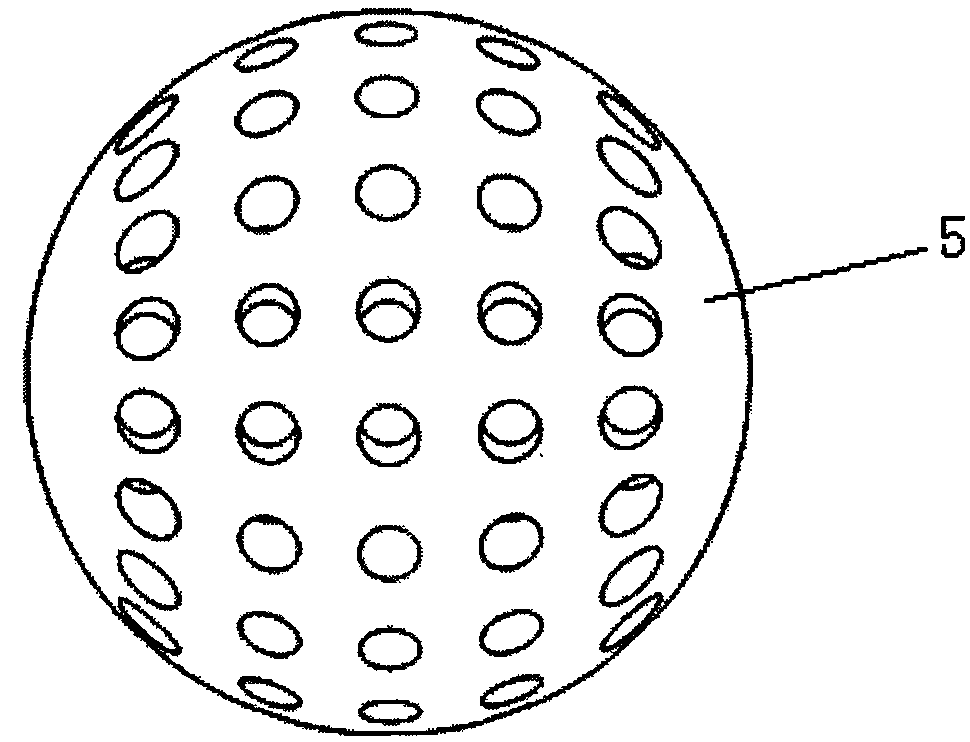

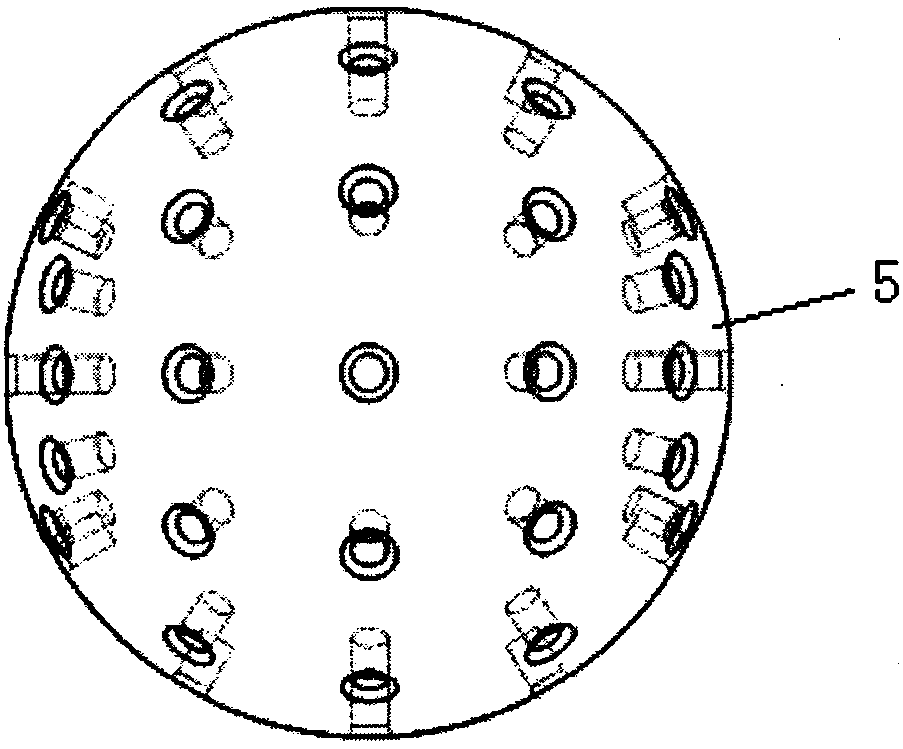

[0032] The nozzle diameter is selected to be 60 mm; a hole 13 is distributed on the spherical surface 12; the holes 13 are uniformly and symmetrically distributed on the spherical surface 12, the number of holes 13 is 60, the diameter is 4 mm, and the depth is 10 mm. The hole 13 has a chamfered structure extending to the outer edge at the spherical surface 12, and the depth of the chamfered structure is 1mm.

[0033]The metal drum 7 is grounded 9, and the distance between the metal drum 7 and the porous spherical electrospinning nozzle 5 is adjusted to be 20cm; the motor 2 6 is turned on, and the rotating speed of the metal drum 7 is set to be 60r / min; the switch of the liquid ...

Embodiment 2

[0035] A method of electrospinning:

[0036] The spinning solution 14 uses a polymer solution prepared from polyacrylonitrile (PAN) and N-N dimethylformamide (DMF) to prepare nanofibers with controllable multi-level diameter distribution. The mass fraction of the prepared PAN polymer solution is 14%.

[0037] The nozzle diameter is selected to be 60mm; a hole 13 is distributed on the spherical surface 12; the holes 13 are evenly and symmetrically distributed on the spherical surface 12, the number of holes 13 is 60, the diameter is 6mm, and the depth is 10mm. The hole 13 has a chamfered structure extending to the outer edge at the spherical surface 12, and the depth of the chamfered structure is 1 mm.

[0038] The metal drum 7 is grounded 9, and the distance between the metal rotating drum 7 and the porous spherical electrospinning nozzle 5 is adjusted to be 22cm; the motor 2 6 is turned on, and the rotating speed of the metal drum 7 is set to be 80r / min; the switch of the li...

Embodiment 3

[0040] A method of electrospinning:

[0041] The spinning solution 14 uses a polymer solution prepared from polyacrylonitrile (PAN) and N-N dimethylformamide (DMF) to prepare nanofibers with controllable multi-level diameter distribution. The mass fraction of the prepared PAN polymer solution is 10%.

[0042] The nozzle diameter is selected to be 60 mm; a hole 13 is distributed on the spherical surface 12; the holes 13 are evenly and symmetrically distributed on the spherical surface 12, the number of holes 13 is 60, the diameter is 4 mm, and the depth is 5 mm. The hole 13 has a chamfered structure extending to the outer edge at the spherical surface 12, and the depth of the chamfered structure is 1 mm.

[0043] The metal drum 7 is grounded 9, and the distance between the metal drum 7 and the porous spherical electrospinning nozzle 5 is adjusted to be 16cm; the motor 2 6 is turned on, and the rotating speed of the metal drum 7 is set to 40r / min; the switch of the liquid suppl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com