Metal appearance-imitated polypropylene-surlyn composite material and preparation method thereof

A technology of sarin resin and composite materials, which is applied in the field of polymer materials, can solve environmental protection and other problems, and achieve the effects of improving scratch resistance, low-temperature brittleness, dispersion and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] 1) Preparation of special effect toner:

[0047] Add the special effect pigment with a particle size of 10-50 microns into the aqueous solution of the emulsifier, and use an ultrasonic disperser to disperse. After ultrasonic dispersion for 10 minutes, install a stirrer and a heating device, raise the temperature to 80°C, add the initiator, and drop Add a certain amount of mixed monomers of methyl methacrylate and acrylic acid to carry out emulsion polymerization, and keep warm for 30 minutes after the monomers are added dropwise to obtain a special-effect toner coated with an organic film.

[0048] 2) Preparation of metal-like appearance polypropylene-surrin composite material:

[0049] After mixing polypropylene, sarin resin, toughener, antioxidant and lubricant evenly, add them into the twin-screw extruder, and then add the special effect toner after 1) treatment and the reinforcing agent in the formula ratio And the light stabilizer is added from the side feeder, ex...

Embodiment 1

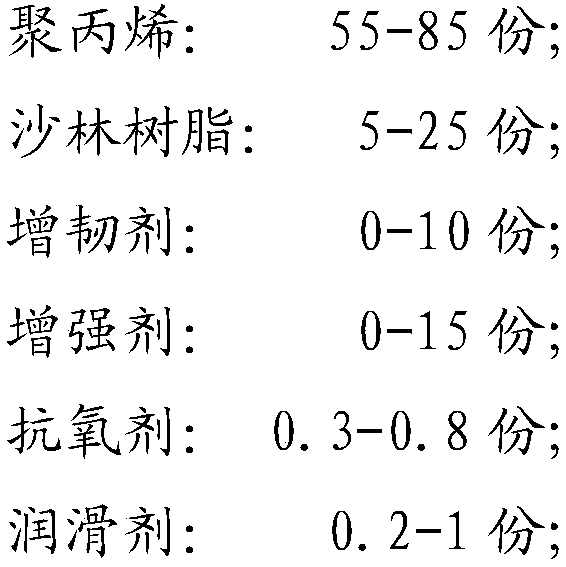

[0052] The metal-like appearance polypropylene-surrin composite material in this example is made up of the following raw materials by weight:

[0053]

[0054]

Embodiment 2

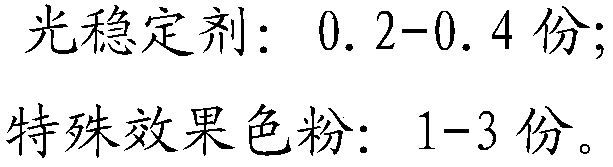

[0056] The metal-like appearance polypropylene-surrin composite material in this example is made up of the following raw materials by weight:

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com