In-situ reaction forming device for differential and integral calculus laminated polymer composite material and in-situ reaction forming method

A molding device and in-situ reaction technology, which is applied in the field of advanced manufacturing of polymer materials to achieve the effects of easy and uniform dispersion, low viscosity and saving of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

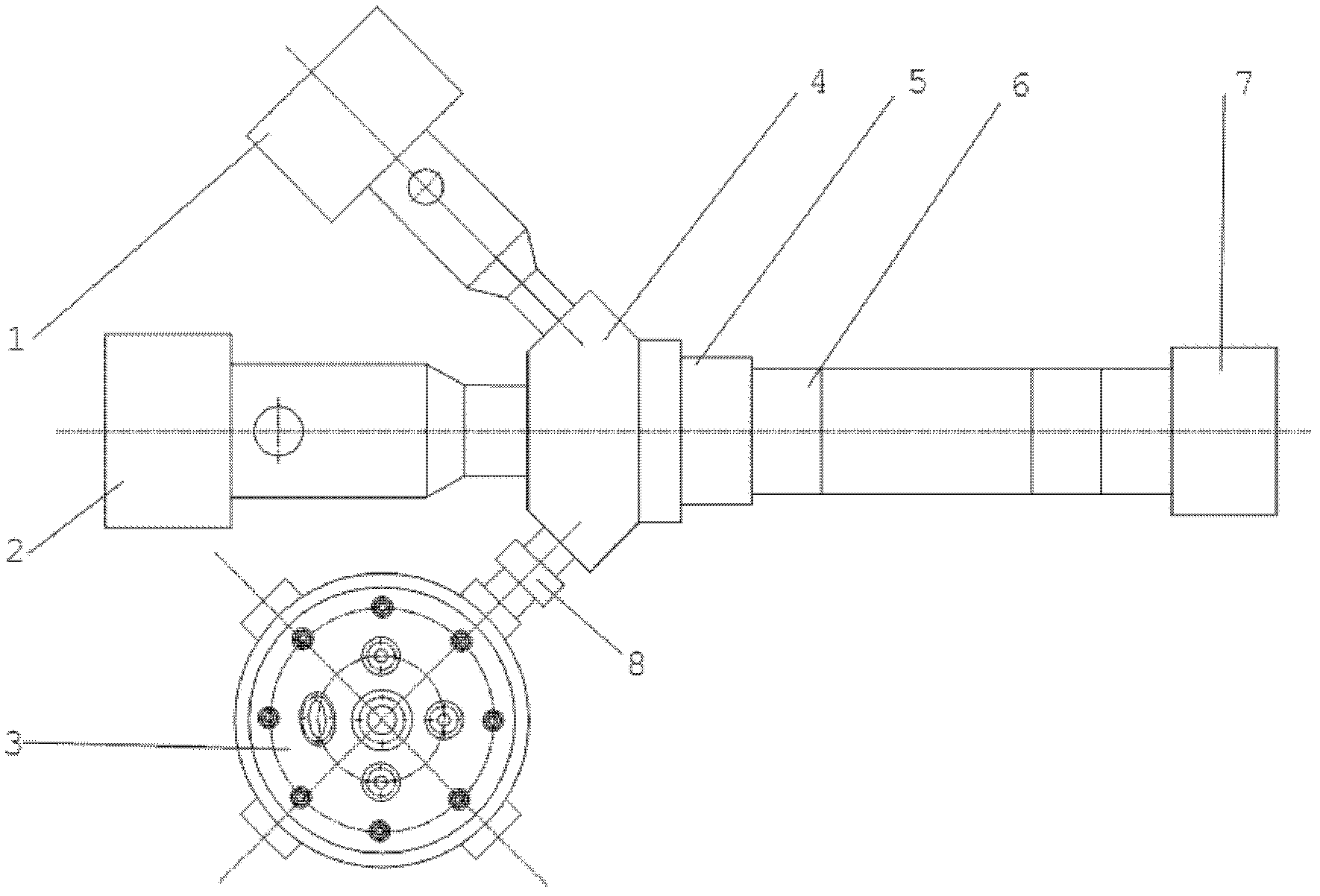

Method used

Image

Examples

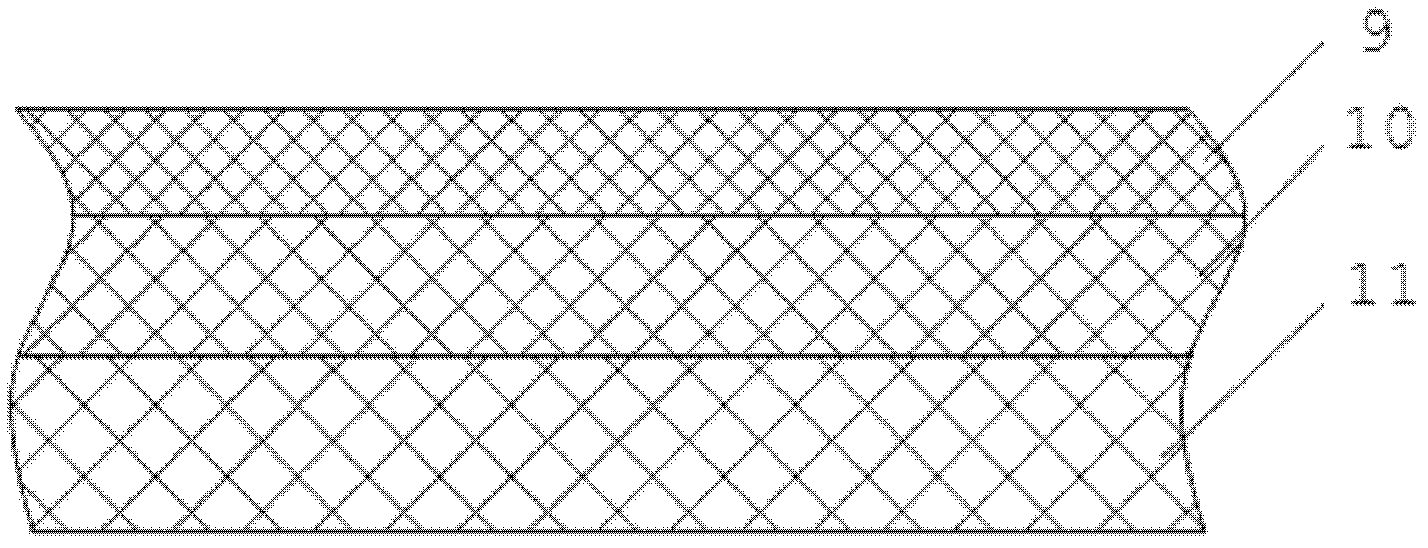

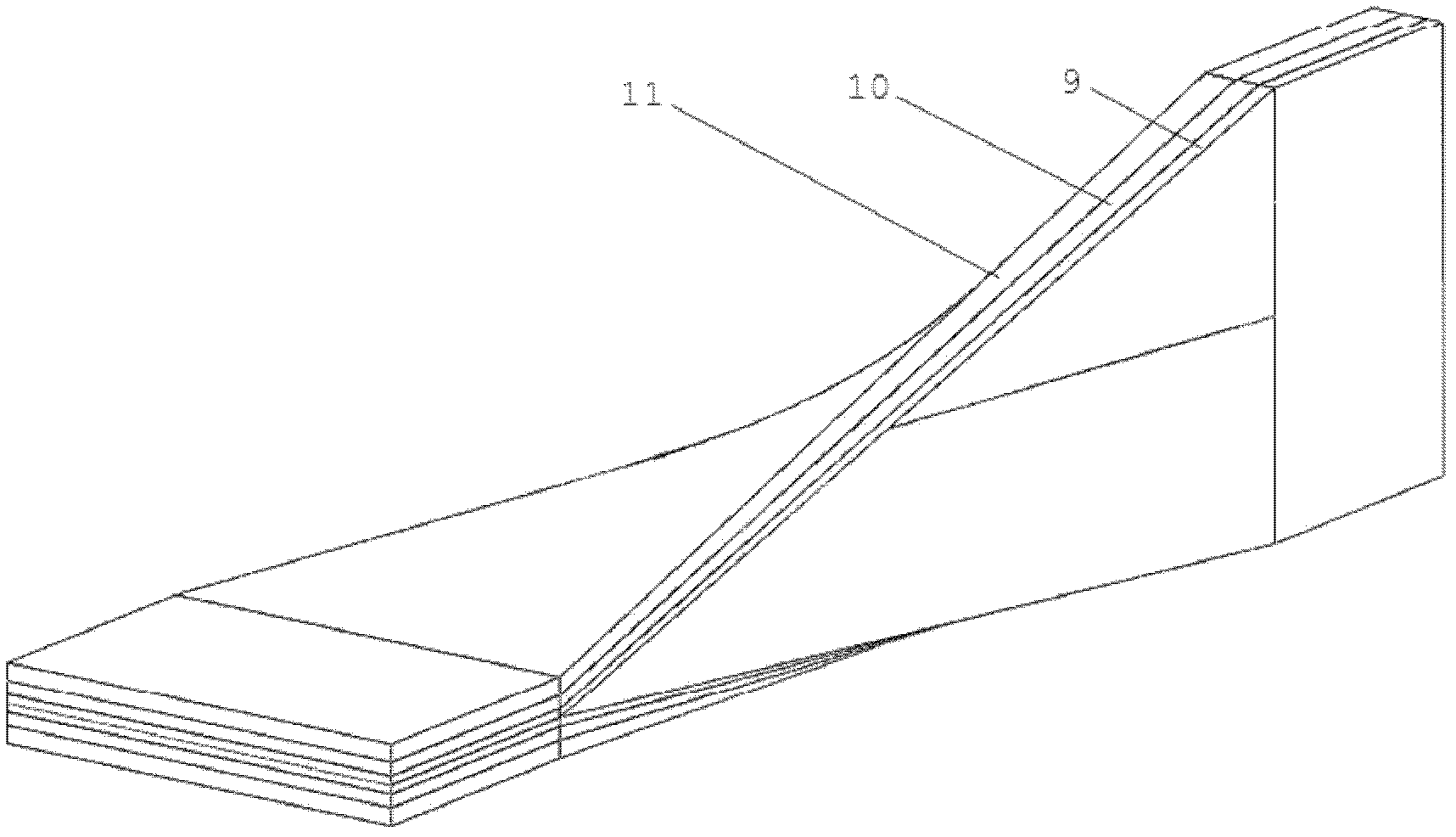

Embodiment 1

[0022] The present invention is a calculus laminated polymer composite material in-situ reaction molding method. The raw material of the base layer 11 is polyethylene, the raw material of the bonding layer 10 is ethylene-vinyl acetate copolymer, and the raw material monomer of the functional layer 9 is caprolactam. The molecular modifier is at least one of carbon nanotubes, layered silicate, and inorganic nanoparticles, the catalyst is sodium hydroxide, sodium methoxide or sodium ethoxide, and the activator is acid chloride, acid anhydride, isocyanate, N-acylation At least one of lactam compounds. First, add caprolactam and polymer modification additives into the vacuum reactor, turn on the vacuum pump to reduce the pressure and heat to melt, vacuum dehydration at 70~120℃, maintain 10~20min; release the vacuum, add the catalyst and heat to 90~130 under vacuum conditions ℃ for a certain period of time; fill the inert gas nitrogen to balance the pressure in the kettle with the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com