Conductive aluminum paste for back passivation solar cell and preparation method thereof

A technology for solar cells and aluminum paste, applied in the field of solar cells, can solve problems such as aluminum back field shedding, and achieve the effects of reducing defective product rate, avoiding bad appearance and good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

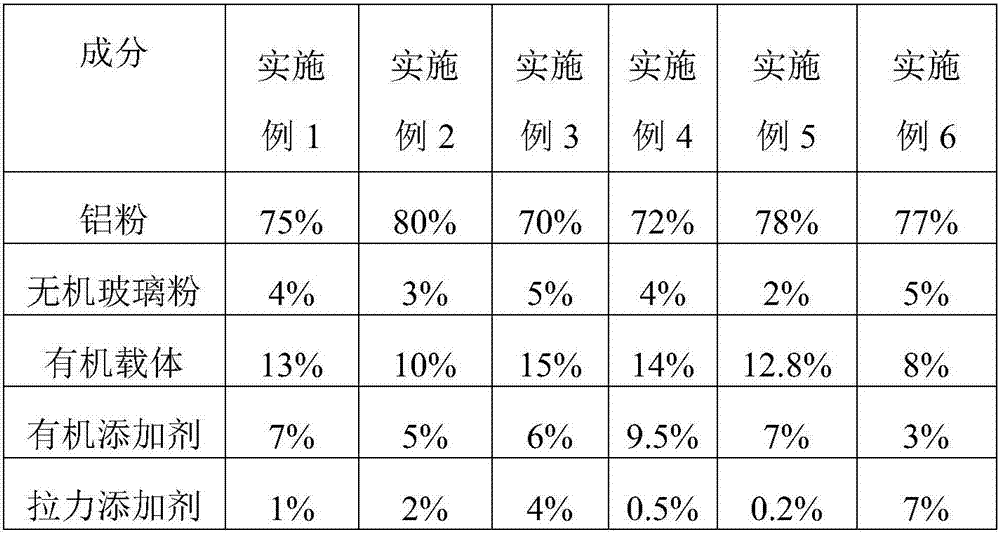

[0030] A kind of conductive aluminum paste for back passivation solar cell, the composition of this conductive aluminum paste weight percentage is as shown in table 1;

[0031] Table 1

[0032]

[0033]In the above-mentioned implementation 1, the tension additive is tetraethyl orthosilicate; in embodiment 2, the tension additive is silicone resin; in embodiment 3, the tension additive is trapezoidal polyorganosilsesquioxane; implementation In Example 4, the tension additive is a ring ladder polyphenylsilsesquioxane; in Example 5, the tension additive is a polyphenylsilsesquioxane ladder polymer; in Example 6, the The tension additive is double-chain ladder poly(1,3-dimethyl-1,3-dioxodisiloxane);

[0034] In above-mentioned embodiment 1~6, described organic vehicle comprises the composition of following percentage by weight: hydroxypropyl methylcellulose 8%, organic solvent 85%, dispersant 4%, leveling agent 3%; Described organic solvent is Diethylene glycol butyl ether; t...

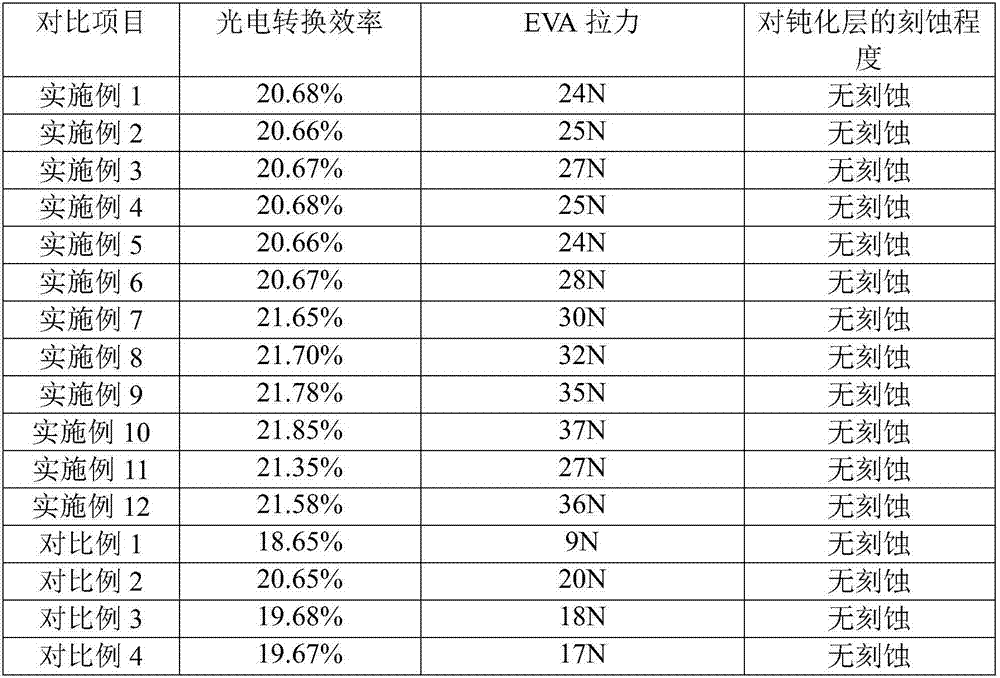

Embodiment 7

[0039] The tension additive is tetraethyl orthosilicate, polyphenylsilsesquioxane ladder polymer and double-chain ladder poly(1,3-dimethyl-1,3- Dioxodisiloxane), it is exactly the same with process parameter and process engineering and embodiment 1.

Embodiment 8

[0041] The tension additive is ladder polyorganosilsesquioxane, orthosilicate, ring ladder polyphenylsilsesquioxane and double chain ladder poly(1, 3-Dimethyl-1,3-dioxodisiloxane). It is identical with process parameter and process engineering and in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com