Method for preparing nickel catalyst supported on SiO2 microspheres and application of nickel catalyst

A technology of nickel catalyst and microspheres, which is applied in the field of catalyst preparation, can solve the problems of low utilization rate of metal Ni, increase of catalyst cost, unutilization of fine powder, etc., achieve low surface acidity, avoid increased side reactions, and reduce cost The effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

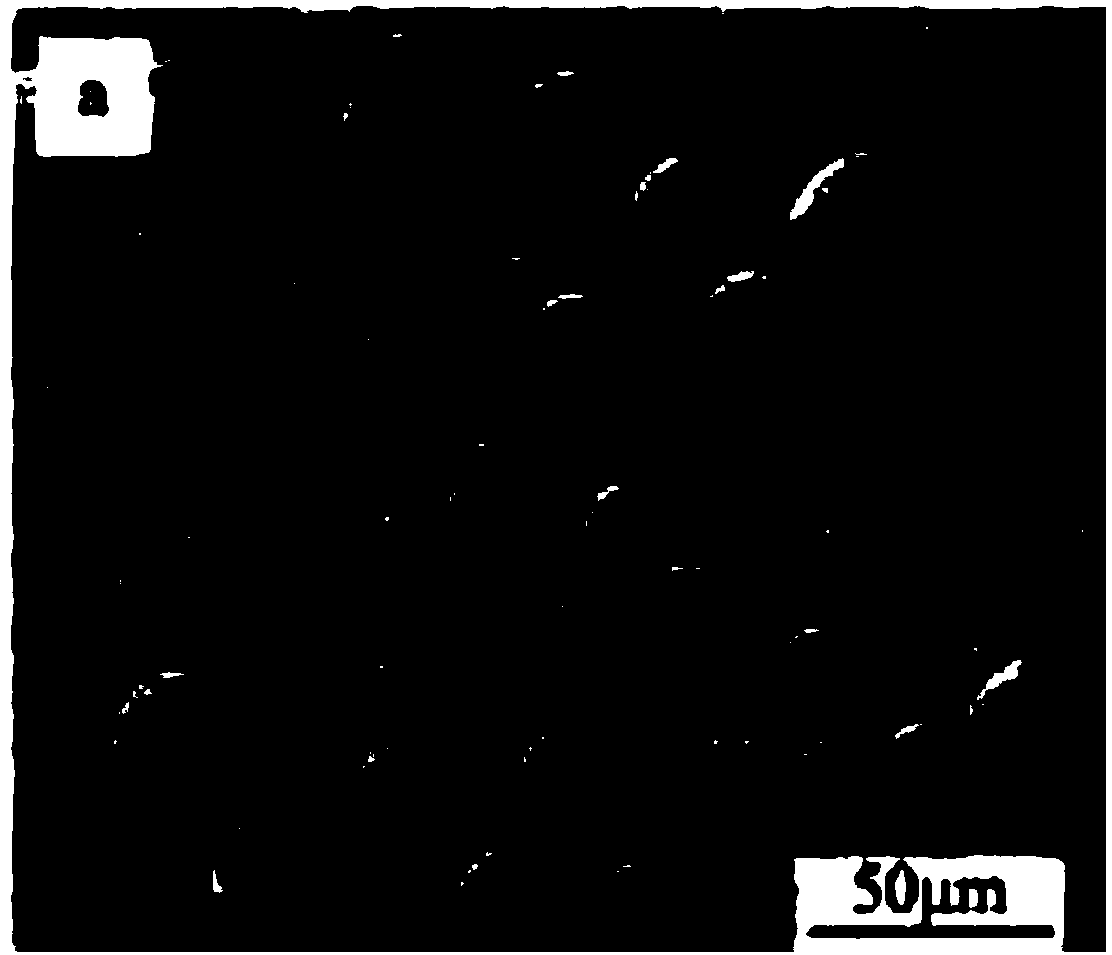

Image

Examples

Embodiment 1

[0043] Preparation of Solution A: Weigh 500g of distilled water, add 50g of methyl orthosilicate and 100g of formic acid, stir for 100min, and distill to 200ml under reduced pressure. Configuration of emulsifier B: Measure 450ml of phenylethyl alcohol into a three-necked bottle, add 45ml of methylcellulose aqueous solution and 15ml of OP-10, and stir until clear. Preparation of solution C: Weigh 30g of nickel acetate and 4.5g of molybdenum acetate into 115.5g of dilute ammonia water, stir to dissolve. Turn on the stirring, adjust the speed to 500r / min, add 64ml of solution A to the three-necked flask containing emulsifier B, stir and emulsify for 90min, distill off water under reduced pressure at 70°C, filter with suction, wash with deionized water and ethanol three times each, Dry in vacuum at 50°C. Add the filter cake to 200g of ammonia solution with a pH of 9.5, stir, heat to 80°C, and treat for 12hr; add 140g of solution C to the treatment liquid, remove water by rotary e...

Embodiment 2

[0048] Preparation of solution A: Weigh 250g of distilled water, add 50g of ethyl silicate and 50g of acetic acid, stir for 80min, and distill to 90ml under reduced pressure. Configuration of emulsifier B: Measure 300ml of phenylethyl alcohol into a three-necked bottle, add 30ml of methylcellulose aqueous solution and 15ml of OP-8, and stir until clear. Preparation of solution C: Weigh 25g of nickel oxalate, 2g of iron acetate and 2g of manganese acetate into 221g of dilute ammonia water, stir to dissolve. Turn on the stirring, adjust the rotation speed to 400r / min, add 68ml of solution A to the three-necked flask containing emulsifier B, stir and emulsify for 30min, distill off water under reduced pressure at 70°C, filter with suction, wash with deionized water and ethanol three times each, Dry in vacuum at 50°C. Add the filter cake to 200g of ammonia solution with a pH of 8.5, stir, heat to 70°C, and treat for 8hr; add 240g of solution C to the treatment liquid, remove wate...

Embodiment 3

[0053] Preparation of Solution A: Weigh 400g of distilled water, add 50g of ethyl silicate and 75g of acetic acid, stir for 90min, and distill to 150ml under reduced pressure. Configuration of emulsifier B: Measure 380ml of phenylethyl alcohol into a three-necked bottle, add 30ml of methylcellulose aqueous solution, 10ml of OP-6, 5ml of OP-7, and stir until clear. Preparation of solution C: Weigh 15g of nickel oxalate, 12g of nickel acetate, 2g of copper acetate and 2g of iron acetate into 200g of dilute ammonia water, stir to dissolve. Turn on the stirring, adjust the rotation speed to 450r / min, add 100ml of solution A to the three-necked flask containing emulsifier B, stir and emulsify for 60min, distill off water under reduced pressure at 70°C, filter with suction, wash with deionized water and ethanol three times each, Dry in vacuum at 50°C. Add the filter cake to 200g of ammonia solution with a pH of 9.0, stir, heat to 75°C, and treat for 10hr; add 220g of solution C to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com