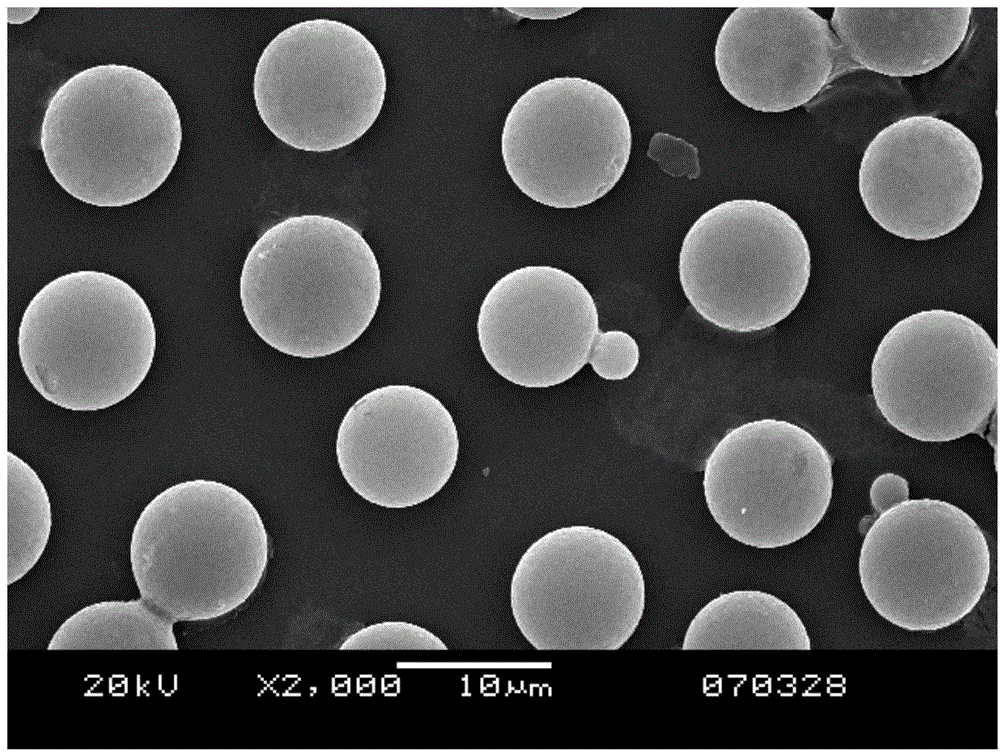

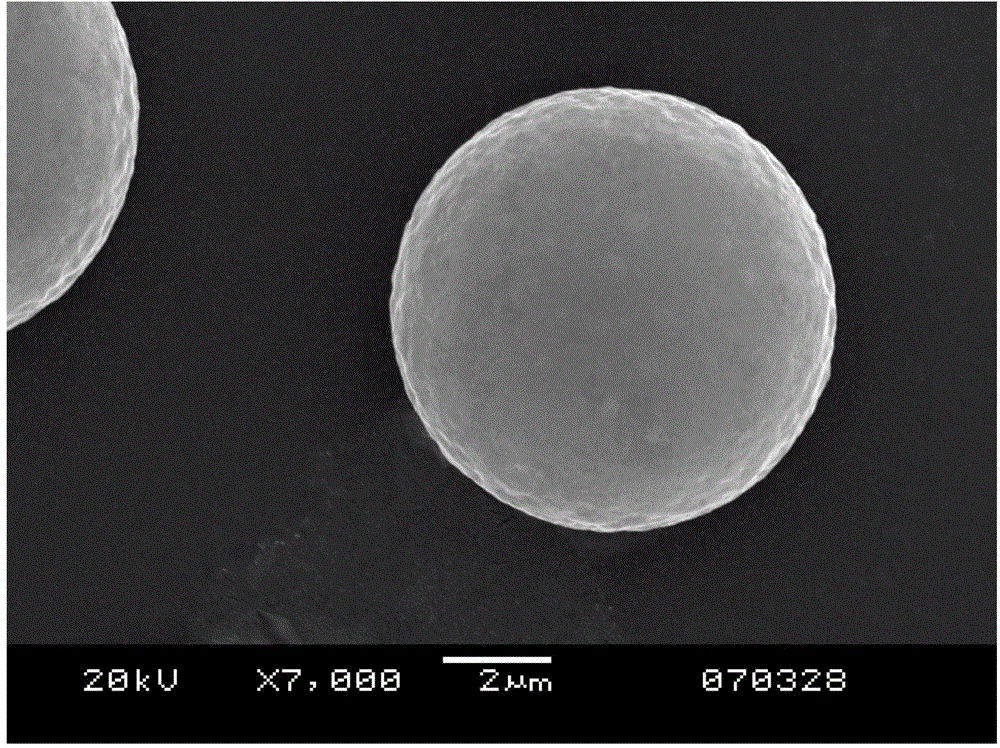

Preparation method and application of Co/Ni and aluminum pyrophosphate composite hollow microsphere

A technology of aluminum pyrophosphate and aluminum phosphate, which is applied in the field of preparation of hollow microspheres, can solve the problems of no hollow microsphere catalysts, difficulty in uniform dispersion of catalysts, and high unit consumption of product catalysts, and achieve uniform size, smooth surface, and selectivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

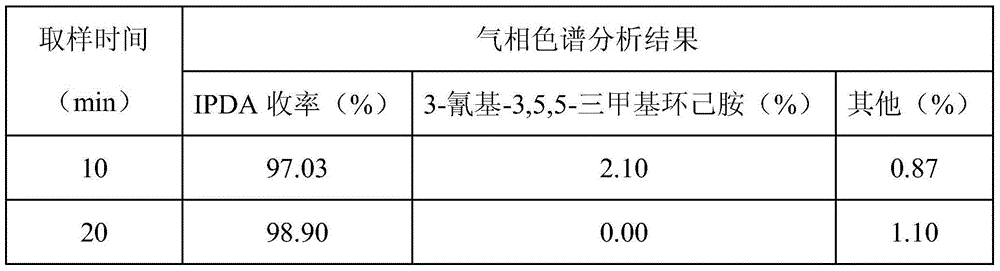

Examples

Embodiment 1

[0042] Preparation of Solution A: Weigh 500g of distilled water, add 4g of 85% H 3 PO 4 Adjust its pH value to about 2; weigh 9.15g Ni (NO 3 ) 2 and 91.5gCo(NO 3 ) 2 Add to pH ≈ 2 phosphoric acid aqueous solution, stir to dissolve. Preparation of solution B: weigh 53.25gAl(NO 3 ) 3 and 30gNaH 2 PO 4 Add to 400g distilled water, stir to dissolve. Preparation of Solution C: Weigh 39.9g of urea and 55g of diethylenetriamine into 500g of distilled water, stir to dissolve. Heat the 2L autoclave (Weihai Chemical Machinery Equipment Co., Ltd.) and set the temperature to 120°C. When the temperature in the autoclave reaches 120°C, inject solution B into the autoclave with an advection pump (Beijing Satellite Manufacturing Factory), and stir The speed is 348 rpm, and the reaction is 5 minutes; then put the solutions A and C into the autoclave at the same time, after the feeding is completed, react at 120°C for 5 hours, then stop heating, wait until the temperature in the kettl...

Embodiment 2

[0044] Preparation of Solution A: Weigh 500g of distilled water, add 4g of 85% H 3 PO 4 Adjust its pH value to about 2; weigh 8.28gNi(CH 3 COO) 2 and 125g Co(CH 3 COO) 2 Add to pH ≈ 2 phosphoric acid aqueous solution, stir to dissolve. Preparation of Solution B: Weigh 120g Al(NO 3 ) 3 and 74.4g (NH 4 ) 2 HPO 4 Add to 500g distilled water, stir to dissolve. Preparation of Solution C: Weigh 60.2g of urea and 80.8g of triethylenetetramine into 500g of distilled water, stir to dissolve. Heat the 2L autoclave (Weihai Chemical Machinery Equipment Co., Ltd.) and set the temperature to 150°C. When the temperature in the autoclave reaches 150°C, inject solution B into the autoclave with an advection pump (Beijing Satellite Manufacturing Factory), and stir The speed is 492 rpm, and the reaction is 7 minutes; then put the solutions A and C into the autoclave at the same time, after the feeding is completed, react at 150°C for 4 hours, then stop heating, wait until the temperat...

Embodiment 3

[0046] Preparation of Solution A: Weigh 500g of distilled water, add 4g of 85% H 3 PO 4 Its pH value is adjusted to about 2; Weigh 16.6gNi (NO 3 ) 2 and 166gCo(NO 3 ) 2 Add to pH ≈ 2 phosphoric acid aqueous solution, stir to dissolve. Preparation of solution B: weigh 193.2gAl(NO 3 ) 3 and 123.4gKH 2 PO 4 Add to 500g distilled water, stir to dissolve. Preparation of Solution C: Weigh 126.8g of urea and 120.1g of tetraethylenepentamine into 500g of distilled water, stir to dissolve. Heat the 2L autoclave (Weihai Chemical Machinery Equipment Co., Ltd.) and set the temperature to 180°C. When the temperature in the autoclave reaches 180°C, inject solution B into the autoclave with an advection pump (Beijing Satellite Manufacturing Factory), and stir The speed is 564 rpm, and the reaction is 10 minutes; then put the solutions A and C into the autoclave at the same time, after the feeding is completed, react at 180°C for 4 hours, then stop heating, wait until the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com