Coated-modified lithium manganese positive electrode material and preparation method thereof

A positive electrode material, lithium manganese oxide technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as large specific surface area, inability to obtain high-temperature cycle performance, and difficulty in uniformly wrapping coating materials, etc., to achieve excellent high-temperature cycle performance, Improve high-temperature cycle performance and reduce the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Correspondingly, the present invention also provides a method for preparing a coated and modified lithium manganate positive electrode material, comprising the following steps:

[0036] Step a) After uniformly mixing the manganese source compound, the M source compound and the lithium source compound, sintering, crushing, and grading to obtain Li a mn 2-b m b o 4 particles, the Li a mn 2-b m b o 4 The particles have a spherical shape and the crystal planes are connected by curved surfaces without clear edges. M is Li, B, Mg, Ti, V, Cr, Fe, Mn, Co, Ni, Cu, Zn, Zr, Nb, Pd One or more of , Ce, Nd and Dy;

[0037] Step b) the Li a mn 2-b m b o 4 Granules, flux and A source compound are mixed to obtain a mixture, and A is one of Mg, Ti, V, Cr, Fe, Mn, Co, Ni, Cu, Zn, Zr, Nb, Pd, Ce, Nd and Dy or several, A source compound is one or more of A oxide, A phosphate, A silicate and A selenate, 0.9≤a≤1.2, 0≤b≤0.15;

[0038] Step c) roasting, cooling, and crushing the m...

Embodiment 1~10

[0050] According to the raw materials, dosage and conditions shown in Table 1, the coated modified lithium manganate cathode material was prepared according to the following steps:

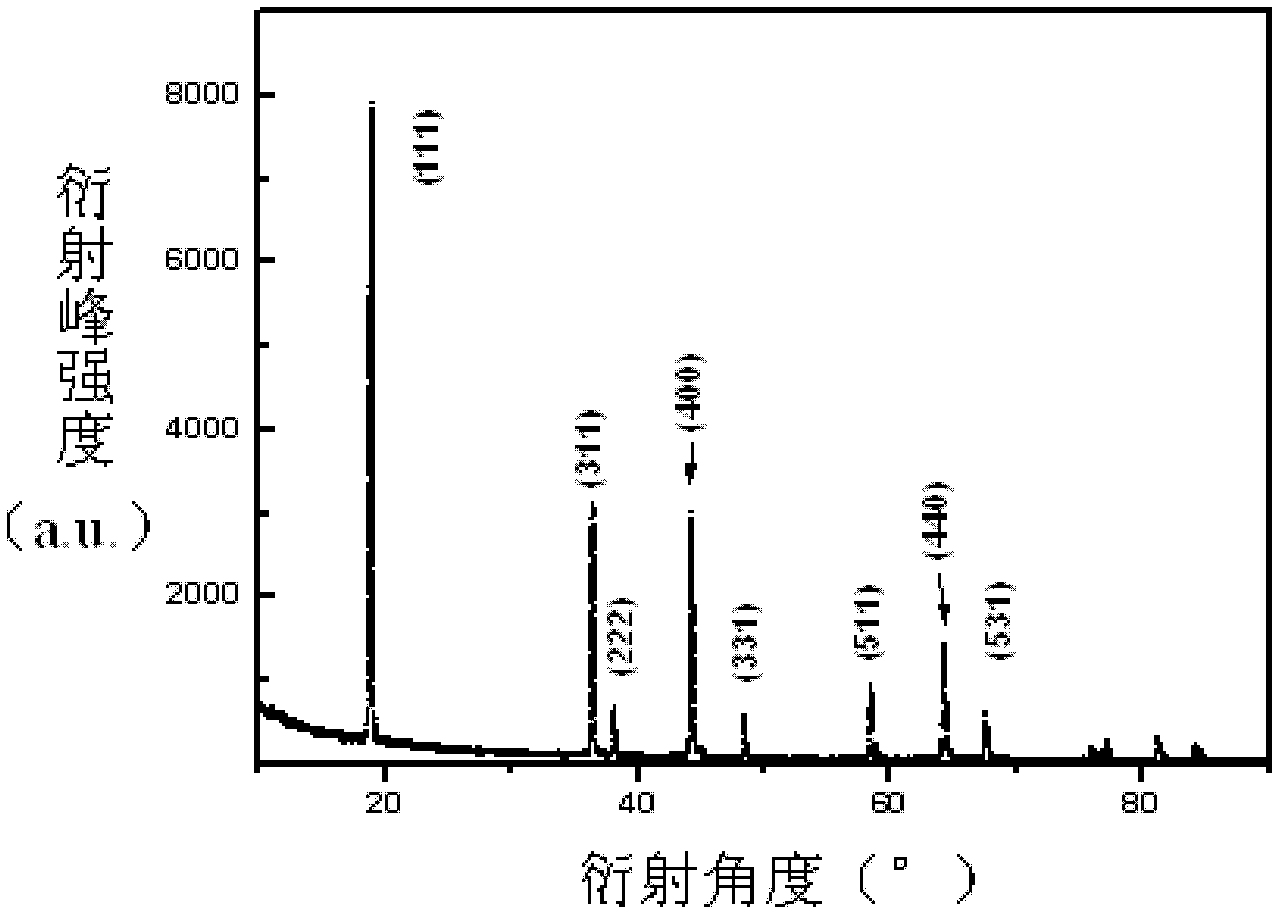

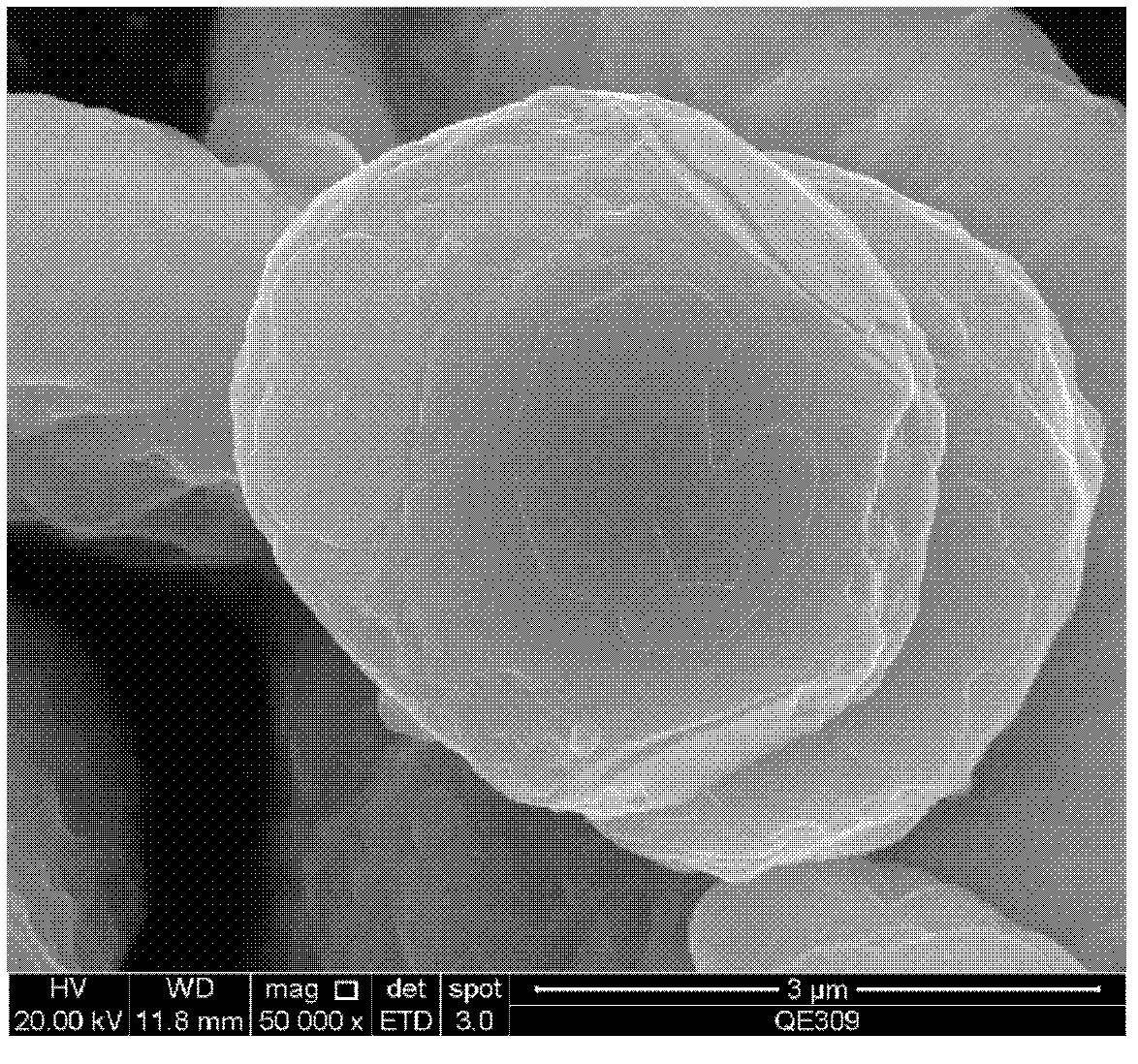

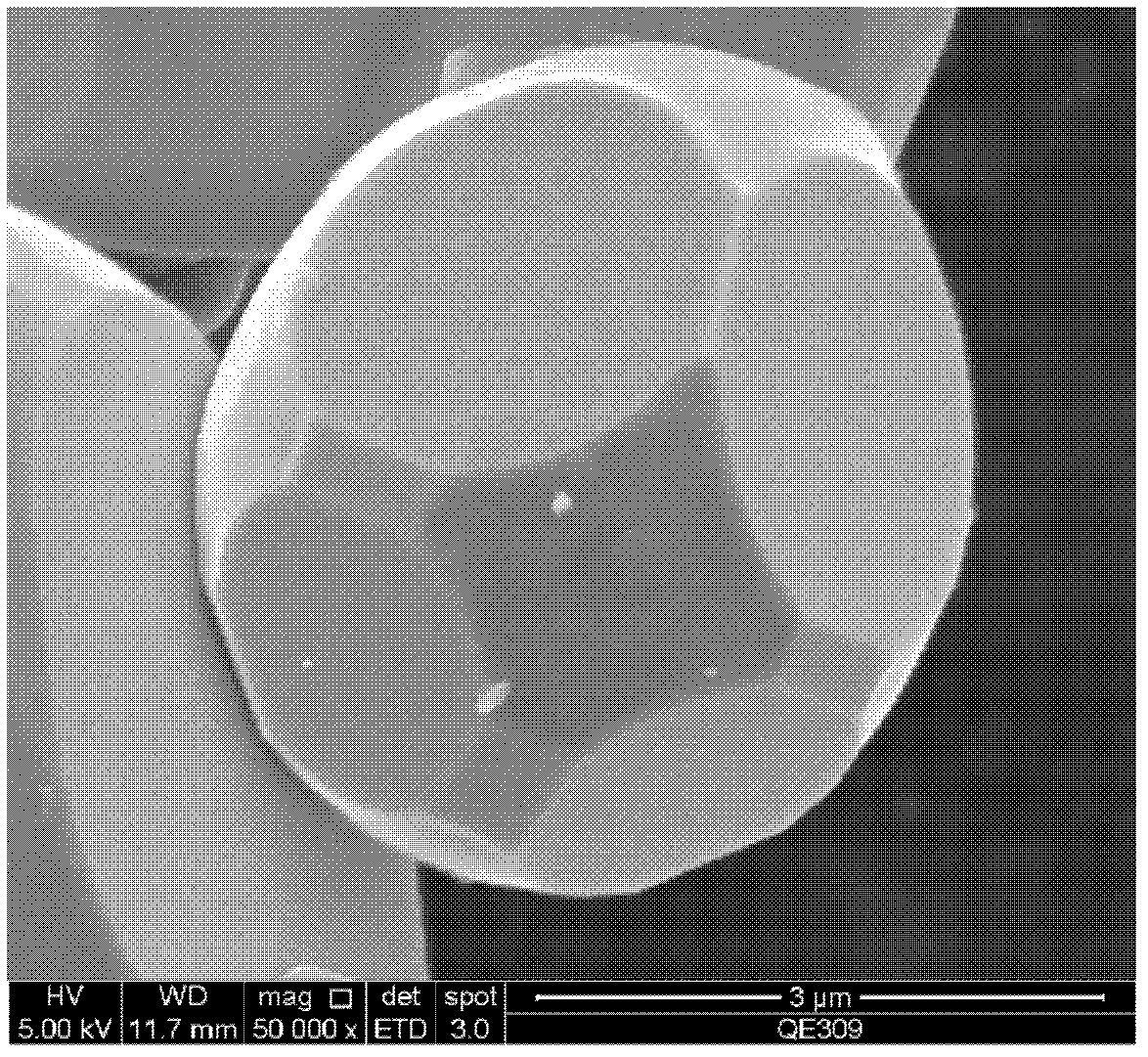

[0051] Mix the manganese source compound, M source compound and lithium source compound evenly, roast, crush, and classify to obtain single crystal particles with a size of 0.1 μm to 20 μm, spherical shape, and crystal planes connected by curved surfaces without clear edges. Li a mn 2-b m b o 4 Particles are lithium manganese oxide cathode materials;

[0052] Mixing the lithium manganate positive electrode material, the melting agent and the oxide of element A, the phosphate of A, the silicate of A or the selenate of A to obtain a mixture;

[0053] The obtained mixture is sintered, cooled, and crushed to obtain a coated and modified lithium manganate positive electrode material.

[0054] Table 1 The formula and conditions for preparing coated and modified lithium manganate cathode materials i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com