Nano barium titanate coated alkyd resin type printing ink

A technology of alkyd resin and barium titanate, which is applied in the field of printing ink to achieve good gloss and toughness, improved performance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

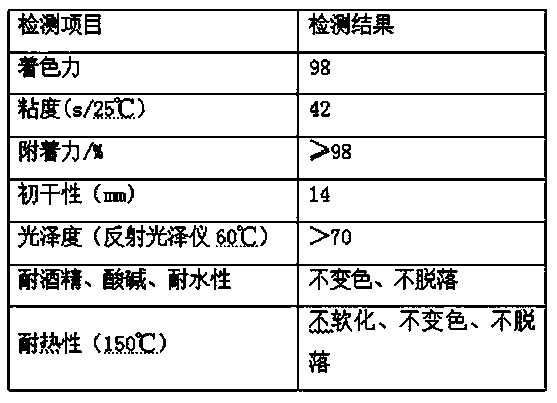

Examples

Embodiment

[0010] The printing ink prepared in this example is made of the following raw materials in parts by weight: polymethyl methacrylate 2, nano barium titanate 2, polylactic acid-glycolic acid copolymer 8, zinc oleate 1, propylene glycol methyl ether 20, alcohol Acid resin 20, ethyl acetate 10, absolute ethanol 5, aluminum gelling agent 3, pigment 12, auxiliary agent 2; wherein the auxiliary agent is made of the following raw materials in parts by weight: triethanolamine 0.1, alumina sol 4, superfine Diatomite 1, limonene 2, absolute ethanol 5, nano-rare earth cerium sol 0.2, the preparation method is: first fully stir and dissolve triethanolamine and limonene in absolute ethanol, then add ultra-fine diatomite, grind and mix for 30 minutes , Concentrate and dry the obtained slurry, and then mix the obtained powder with alumina sol and nano-rare earth cerium sol, stir and disperse evenly.

[0011] The preparation method of the printing ink is as follows: first uniformly disperse na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com