A conductive film and a patterning method thereof

A conductive film and patterning technology, which is applied to conductive materials, conductive materials, conductive layers on insulating carriers, etc., can solve the problems of copper layer being easily oxidized, conductivity changes, surface resistance and conductivity fluctuations, etc., to achieve suppression Effects of natural oxidation, damage suppression, and etching suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

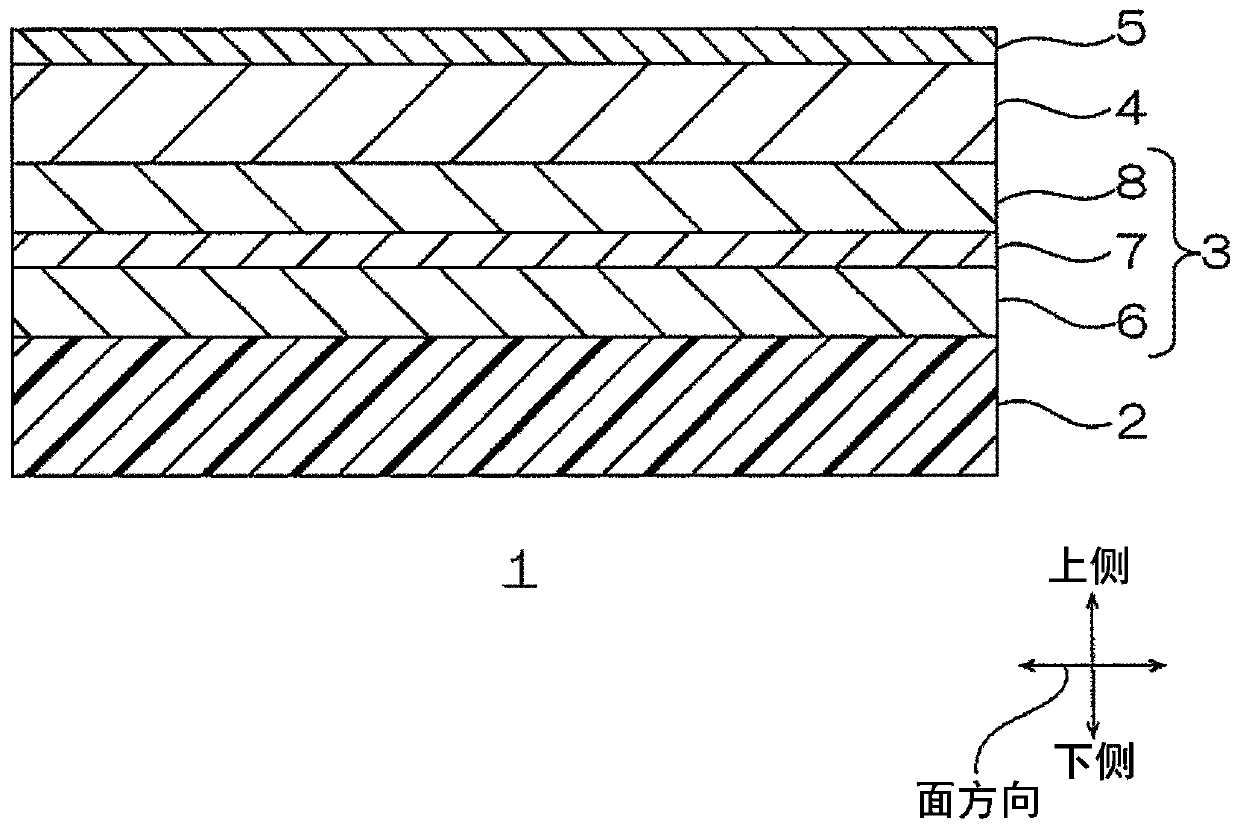

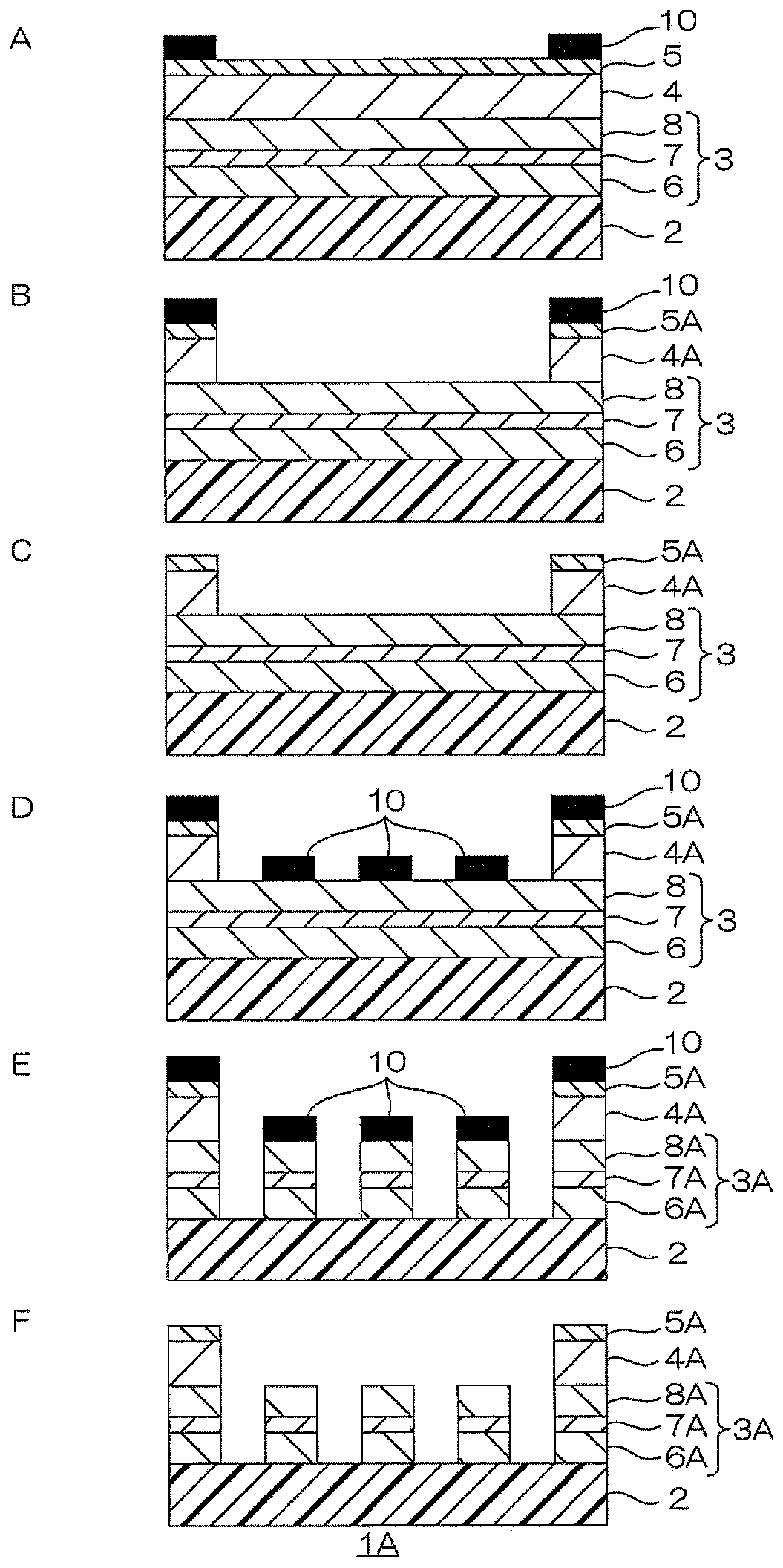

[0156] As a transparent substrate, a polyethylene terephthalate (PET) film with a thickness of 50 μm was prepared.

[0157] Next, the PET film was introduced into a vacuum sputtering device, and an indium tin oxide layer with a thickness of 40 nm, a silver layer with a thickness of 8 nm, and an indium tin oxide layer with a thickness of 36 nm were sequentially formed by sputtering to form a transparent conductive layer.

[0158] In the formation of the indium tin oxide layer, a target made of a sintered body of 12% by mass tin oxide and 88% by mass of indium oxide was used, and a target made of an Ag alloy was used for the formation of the silver layer.

[0159] Next, the PET film on which the transparent conductive layer was laminated was introduced into a vacuum sputtering apparatus, and a copper layer with a thickness of 200 nm was formed by the sputtering method.

[0160] Specifically, the transparent conductive layer was sputtered using a Cu target made of oxygen-free cop...

Embodiment 2~4

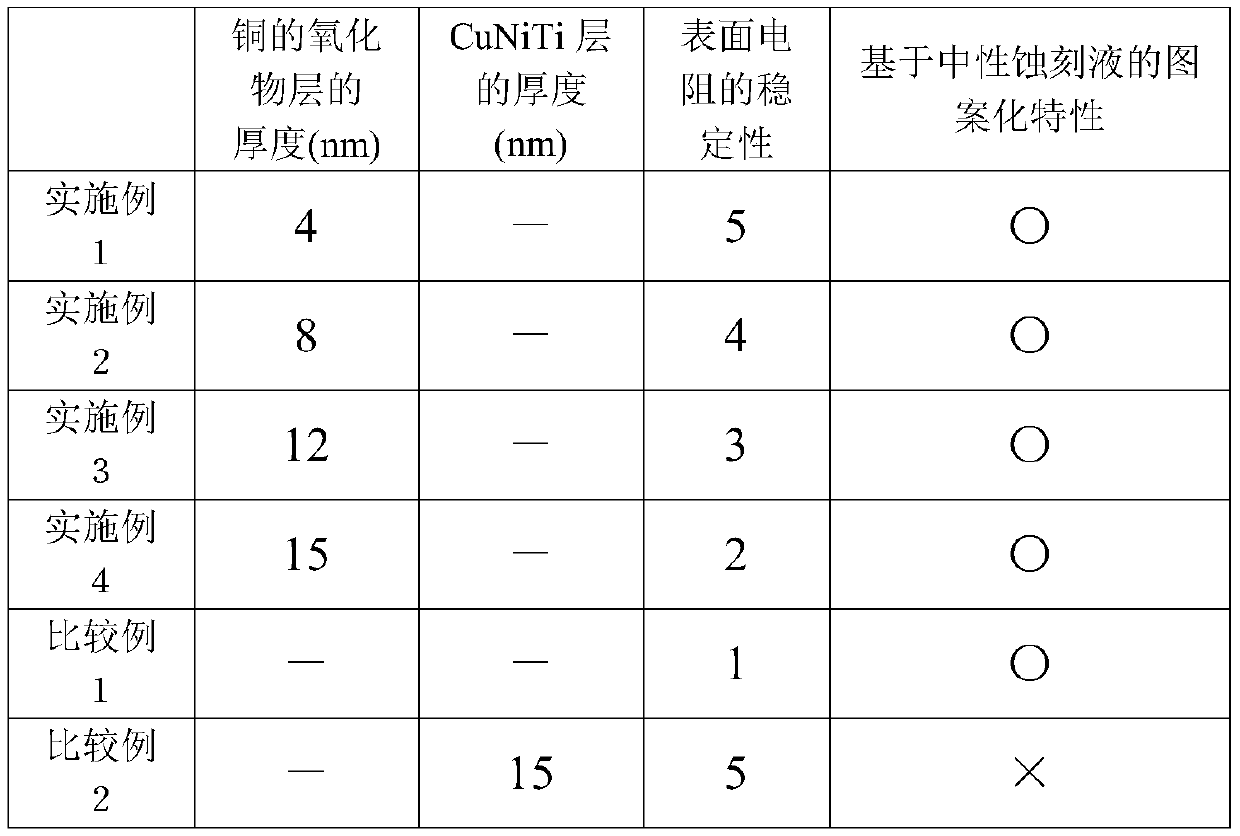

[0165] Except having changed the thickness of the oxide layer of copper into the thickness of Table 1, it carried out similarly to Example 1, and obtained the electroconductive thin film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com