Adsorbent for olefin/alkane mixed gas separation and preparation method and application thereof

A technology of mixed gas and adsorbent, applied in adsorption purification/separation, chemical instruments and methods, other chemical processes, etc., can solve the problems of easily damaged material structure, complex operation process, collapse of pore structure, etc., to achieve good adsorption effect, The effect of high selectivity and easy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Preparation of metal-organic framework materials: add vanadium chloride, terephthalic acid, hydrofluoric acid and water into the reaction kettle according to a certain molar ratio (1:0.25:2:250), stir them evenly with ultrasonic waves, and then After 4 days of reaction at 200°C, MIL-47(V) containing impurities (mainly terephthalic acid in the channels) can be obtained, and the valence state of the initially synthesized metal vanadium is 3+;

[0045] (2) Activation of metal-organic frameworks: take 500 mg of initially synthesized MIL-47 (V 3+ ) into 100ml of DMF, ultrasonicated at 80°C for 2h, centrifuged and repeated ultrasonication twice, then exchanged with methanol for 3 times at 70°C, and finally dried in a vacuum oven at 80°C for 12h. Purified samples were stored in a desiccator. The following examples, unless otherwise specified, are samples purified by this activation method.

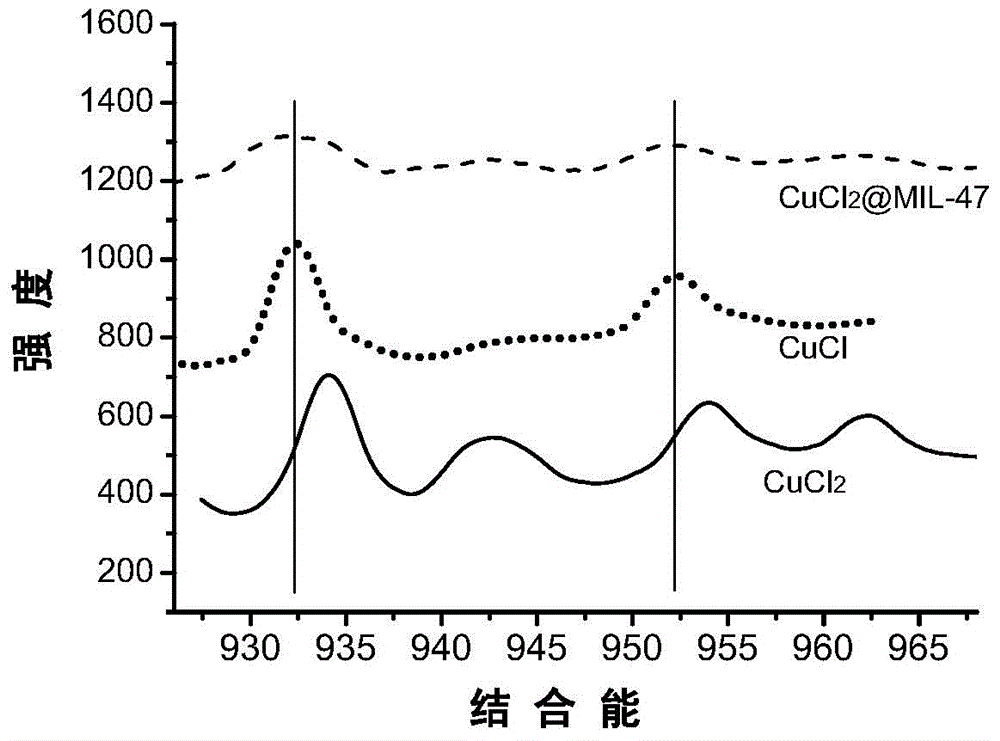

[0046] (3) Preparation of composite adsorbent material: get activated MIL-47 (V ...

Embodiment 2

[0051] Preparation of composite adsorbent material: get the activated MIL-47 (V 3+ ) into the container, add 2 mL of ethanol solution with a cupric chloride concentration of 200 mg / ml, stir for 6 h, filter, and dry in a vacuum oven at 80° C. for 1 h to obtain an adsorbent with a loading capacity of 38.5 wt%.

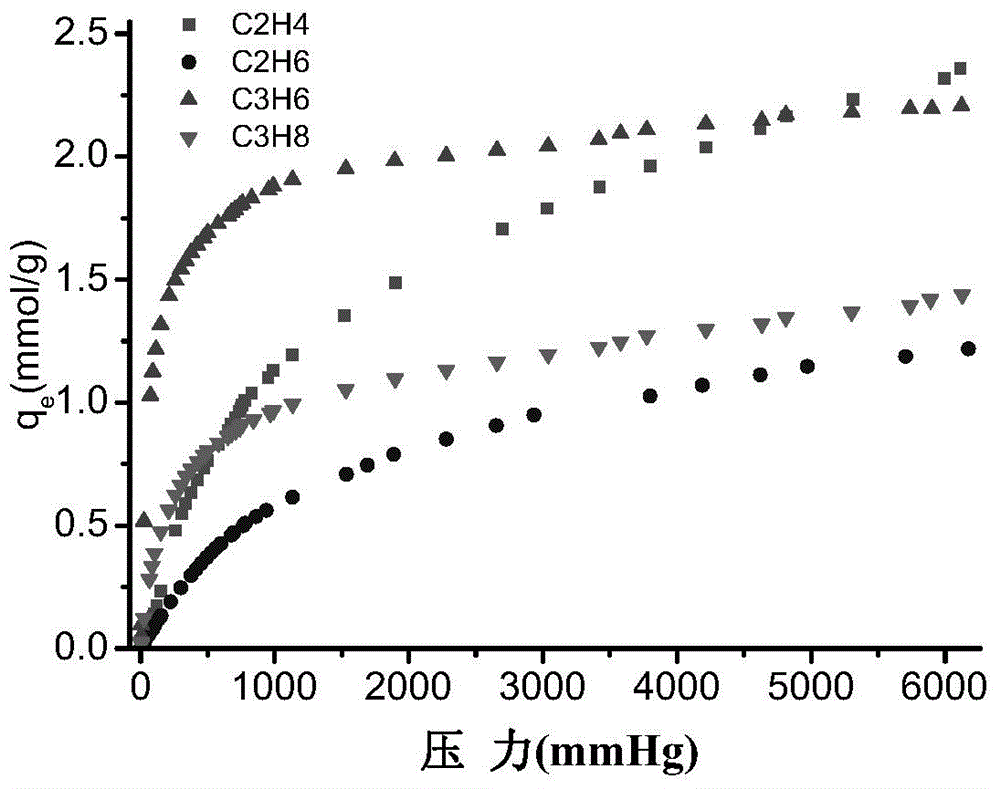

[0052] At 30°C and 1 bar, the adsorption capacity of the adsorbent to ethylene is 1.20 mmol / g, the adsorption capacity to ethane is 0.7 mmol / g, and the equilibrium separation selectivity is 1.71. At 8 bar, the adsorption capacity of the adsorbent to ethylene is 2.56 , the adsorption capacity of ethane is 1.45mmol / g, and the equilibrium separation selectivity is 1.76.

Embodiment 3

[0054] Preparation of composite adsorbent material: get the activated MIL-47 (V 3+ ) into the container, add 2 mL of ethanol solution with a cupric chloride concentration of 300 mg / ml, stir for 6 h, filter, and dry in a vacuum oven at 80° C. for 1 h to obtain an adsorbent with a loading capacity of 54.8 wt%.

[0055] At 30°C and 1 bar, the adsorption capacity of the adsorbent to ethylene is 1.01mmol / g, the adsorption capacity to ethane is 0.50mmol / g, the equilibrium separation selectivity is 1.95, and according to the ideal solution theory (IAST), the equimolar ratio The ideal selectivity of ethylene / ethane calculated under the following conditions is 5. The adsorption capacity of the adsorbent for ethylene at 8 bar is 2.35, the adsorption capacity for ethane is 1.2 mmol / g, and the equilibrium separation selectivity is 2.02. At 1 bar, the adsorption capacity of the adsorbent for The adsorption amount of propylene is 1.81mmol / g, the adsorption amount to propane is 0.91mmol / g, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com