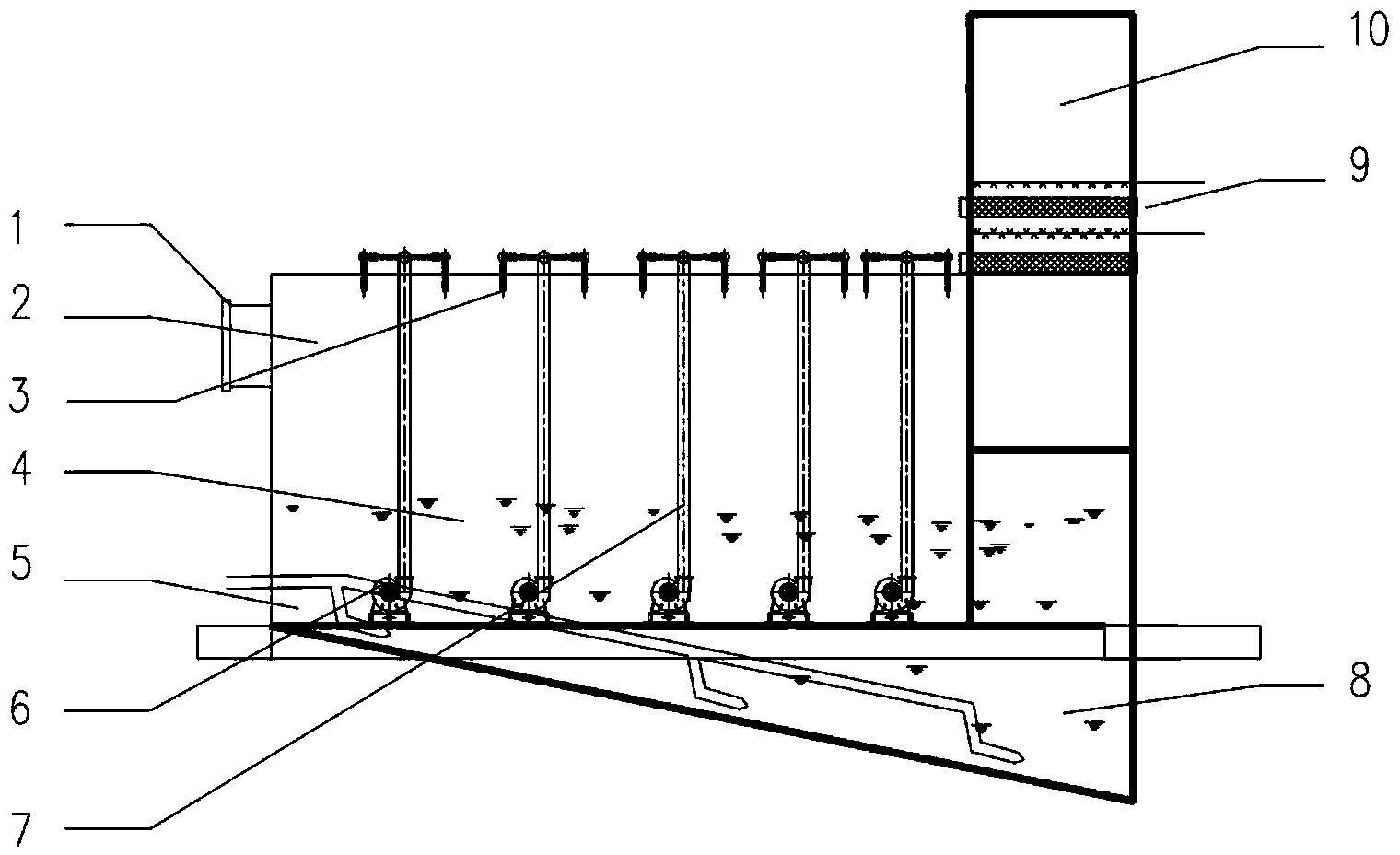

Integrated horizontal wet-process desulfurizing device

A wet desulfurization, horizontal technology, applied in the field of environmental engineering, can solve problems such as large floor area, floating gypsum rain, and excessive dust concentration at the outlet, so as to avoid excessive dust concentration at the outlet, reduce investment and operating costs, and save occupational The effect of the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention adopts an integrated design, and the mixing function area is located at the bottom of the slope of the slurry area, which realizes the integration of the functions of adding new desulfurizer and discharging waste slag, and reduces the occupied area. The slag outlet is set at the bottom, and the waste slag is concentrated by gravity sedimentation and then sucked out by the slag discharge pump. The feeding port is set at a slightly upper position. A new slurry lift pump is installed outside this area, and the lift pump is connected to the slope top area of the slurry area through pipelines. After the new material is pre-mixed at the feeding port, it is lifted to the slope top area by the new slurry lift pump, so as to realize the material circulation inside the desulfurization tower. The desulfurization nozzle is independently installed on the tower wall and extends into the tower for an appropriate distance. It is connected to the spray pipe by a soft co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com