Catalyst waste water zero discharge method and device

A zero-emission, catalyst technology, applied in chemical instruments and methods, natural water treatment, water/sewage treatment, etc., can solve the unstable operation of desalination treatment process units, the difficulty and limitation of catalyst wastewater reuse, and the suspension of secondary sedimentation tank effluent Solve the problem of high concentration of silicon, achieve the effect of increasing the transmission rate and self-cleaning function, avoiding the phenomenon of concentration polarization, and good silicon removal effect

Pending Publication Date: 2016-03-23

GO HIGHER ENVIRONMENT GRP CO LTD

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional method of treating catalyst wastewater in the petrochemical industry is mainly to flocculate by adding polyaluminum or polyacrylamide flocculants in the primary settling tank, which results in a large amount of sludge, high operating costs, unstable operation of the desalination process unit, and effluent from the secondary settling tank. High suspended solids

The quality of effluent water is not up to standard, and there are still certain difficulties and restrictions on the reuse of catalyst wastewater

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0075] Example: the sewage of a catalyst factory, the influent water quality is: SiO 2 200-700mg / L, Ca 2+ The content of SiO is 432-552mg / L, and the turbidity is 10-15NTU. After being treated by a kind of catalyst waste water zero discharge device described in the present invention, SiO 2 ≤1mg / L,Ca 2+ The content is less than 0.2mg / L, and the turbidity is less than or equal to 0.1NTU, meeting the requirements of process recycling.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

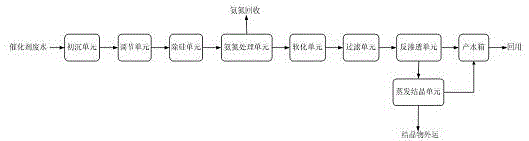

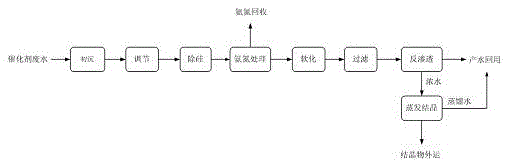

Login to View More Abstract

The invention discloses a catalyst waste water zero discharge method and device. The problems are solved that concentrations of suspensions and ammonia nitrogen in catalyst waste water are high, the content of silicon dioxide fluctuates greatly and addition dosage is hard to control. The catalyst waste water zero discharge device comprises a primary settling unit, an adjusting unit, a silicon removal unit, an ammonia nitrogen processing unit, a softening unit, a filtering unit, a reverse osmosis unit and an evaporation crystallization unit. The beneficial effects are that the problems are solved effectively that the content of silicon dioxide in catalyst waste water fluctuates greatly and the addition dosage is hard to control; in addition, ammonia nitrogen in waste water is recovered, zero discharge of catalyst waste water and resource utilization are achieved, the whole system has a strong impact-resistant load capability, the technology steps are simple, and the problem of environment pollution of catalyst waste water is solved.

Description

technical field [0001] The invention belongs to the field of industrial wastewater treatment, and in particular relates to a method and a device for zero discharge of catalyst wastewater. Background technique [0002] At present, my country's petrochemical industry has ushered in a good opportunity for development. With the advancement of technology in the petrochemical industry, the types of catalysts are increasing and their components are complex, which brings difficulties to environmental governance. On the other hand, the standardization of my country's economic market and the increasing emphasis on environmental protection require us to use water resources reasonably and comprehensively to reduce the harm to the environment. Catalyst wastewater has the characteristics of large fluctuations in the content of ammonia nitrogen, suspended solids and silicon dioxide, and it is difficult to control the dosage. Since the sewage contains a large amount of suspended solids, si...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F9/10C02F103/34

CPCC02F9/00C02F1/048C02F1/441C02F1/52C02F2103/365

Inventor 陈福泰李廷英

Owner GO HIGHER ENVIRONMENT GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com