Resourceful treatment system and process for high-concentration phenolic resin wastewater

A technology of phenolic resin and treatment system, which is applied in water/sewage treatment, water treatment parameter control, biological water/sewage treatment, etc. It can solve the problems of complex composition of phenolic resin wastewater, increased carbon dioxide emissions, and high treatment costs, so as to avoid The effect of effluent exceeding the standard, reducing energy consumption, improving purity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

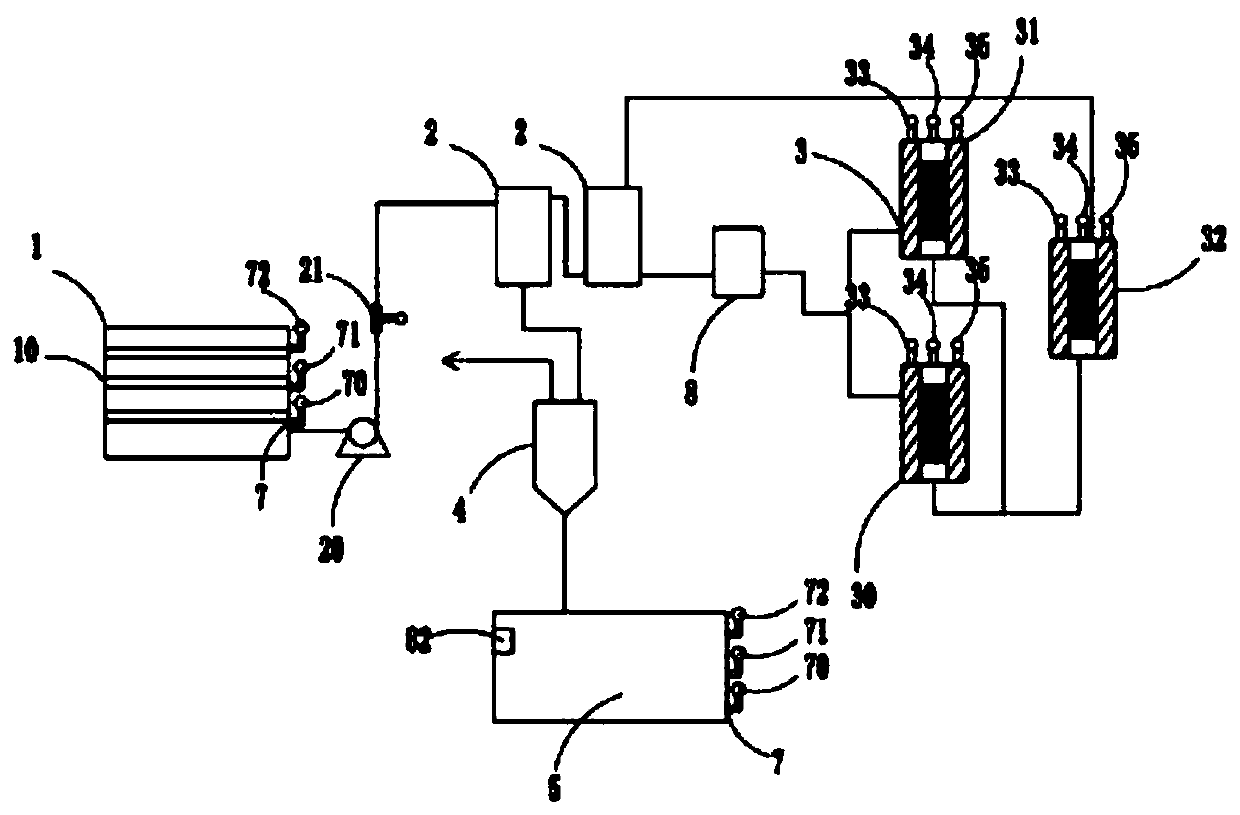

[0037] Example: such as figure 1 The shown resource treatment system for high-concentration phenolic resin wastewater mainly includes a wastewater temporary storage tank 1 with a filtering device 10 inside, which is connected to the wastewater temporary storage tank 1, and the connection is provided with a suction pump 20 and an electromagnetic flowmeter 21, the heat exchanger 2, the reactor 3 connected to the heat exchanger 2, the gas-liquid separator 4 that separates the gas-liquid mixture after heat exchange by the heat exchanger 2, and the gas-liquid separator 4 Temporary storage tank for reused water 5 for temporary storage of liquid, intelligent control element 6, power supply electrically connected to each electrical element;

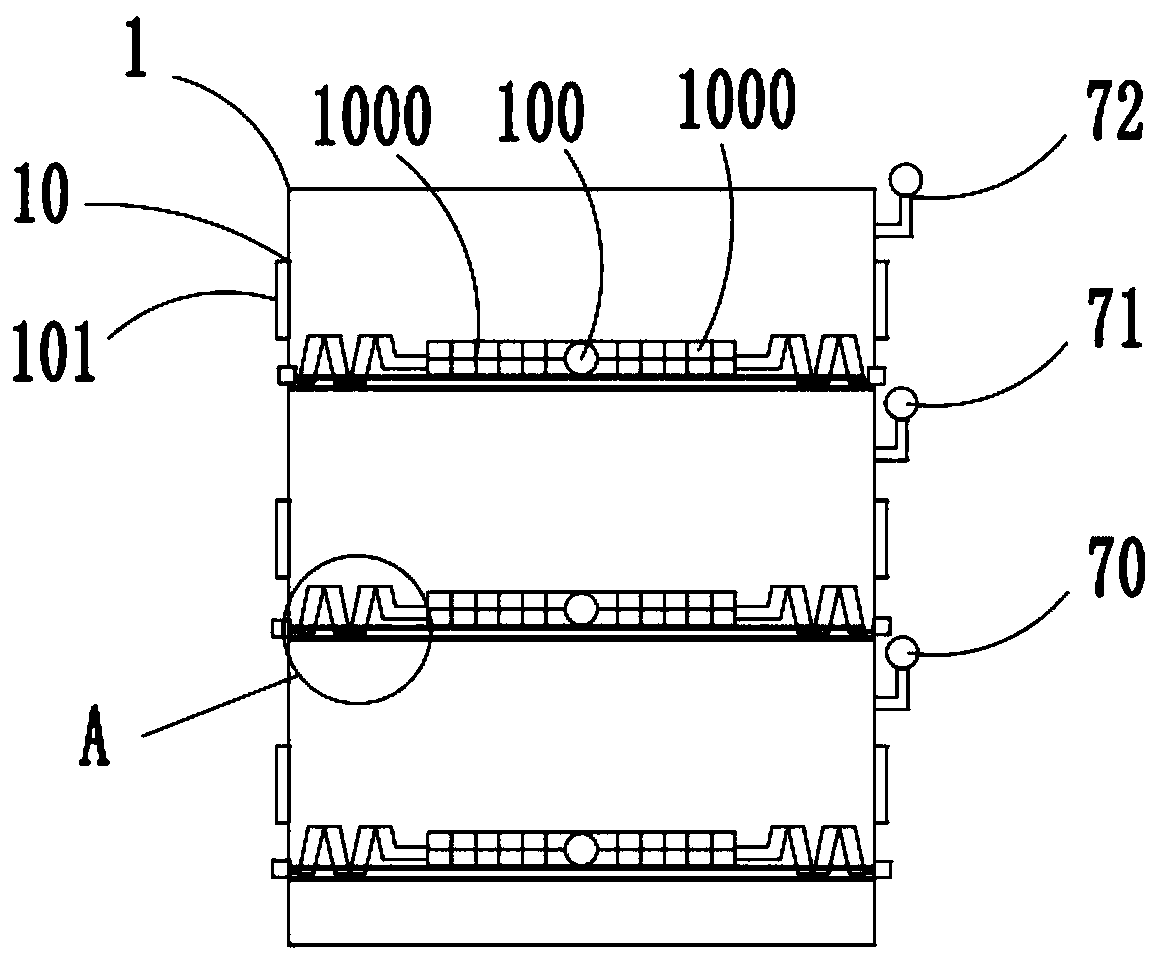

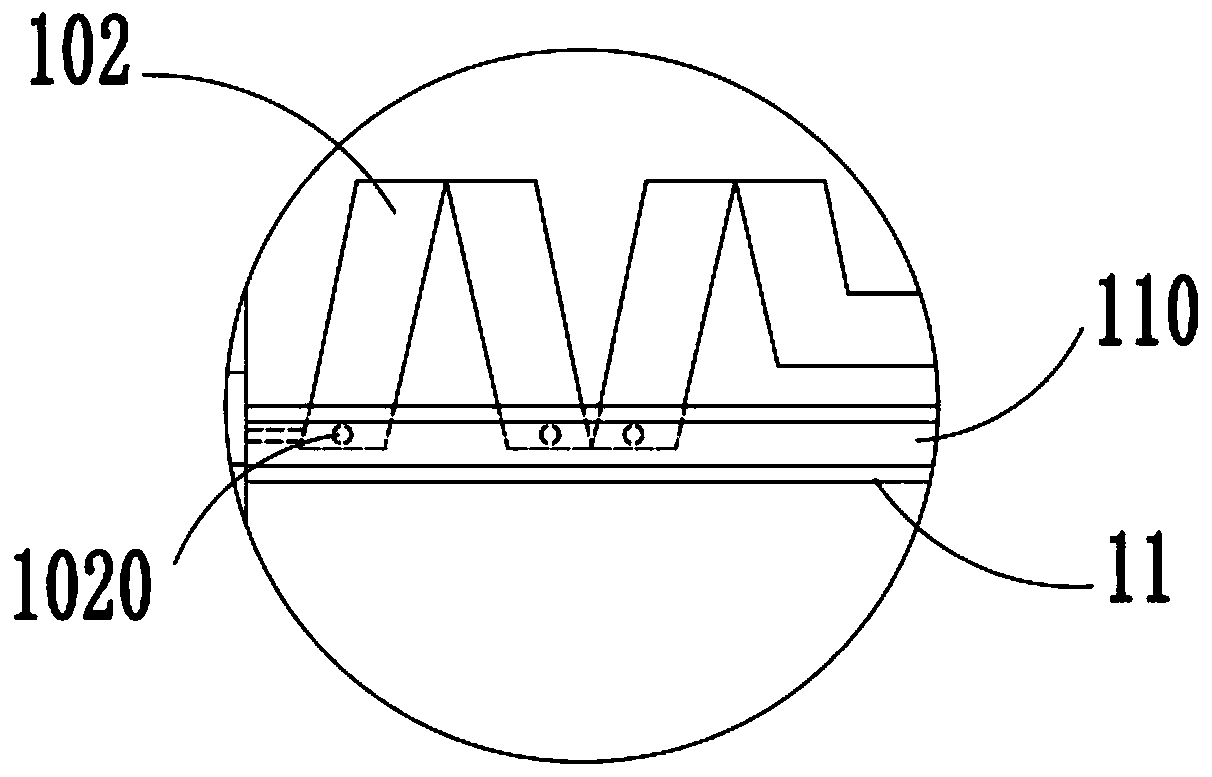

[0038] As shown in 2 and 4, the filter device 10 includes three filter screens 100 arranged horizontally from top to bottom in the wastewater temporary storage tank 1 and gradually increased in mesh number. The six blocking plates 101 at the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com