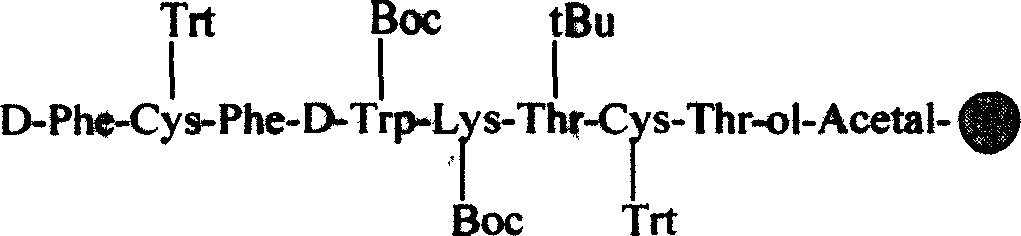

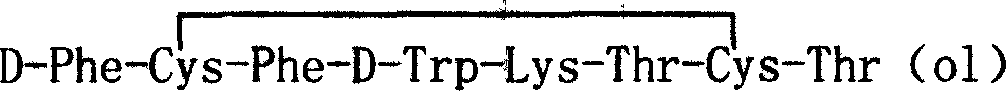

Solid-phase synthesis process of octreotide acetate

A technology for solid-phase synthesis of octreotide acetate, which is applied in the field of solid-phase synthesis of octreotide acetate, can solve the problems of long liquid-phase synthesis preparation time, strong corrosive environmental pollution, severe reaction conditions, etc., and achieve high yield and few side reactions , the effect of fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063]Example 1: Synthesis of Fmoc-Thr-ol-Acetal

[0064] Add Fmoc-Thr-ol (3.28g) into a four-necked flask, dissolve it with anhydrous chloroform (200ml), add 1.90g of p-carboxybenzaldehyde, and add 100mg of p-toluenesulfonic acid, and then heat and reflux in a water bath at 60°C. TLC monitoring, after the reaction was complete, the solvent was concentrated under reduced pressure on a rotary evaporator to obtain a light yellow viscous substance. After diluting the viscous matter, it was subjected to silica gel chromatography, and the developing solution was dichloromethane: ethyl acetate (3:1). The solution was collected, and 3.0 g of the product was obtained after distillation.

[0065] Wherein Fmoc-Thr-ol can be used directly, and can also be prepared by the following embodiment method:

[0066] Add Fmoc-Thr-OH (7.5g) into 100ml THF to dissolve, then add ethyl chloroformate 3.1mL, NMM 3.5mL, and react at 0°C for 10min, then add NaBH 4 1.50g, reacted for 10min and then stir...

Embodiment 2

[0067] Example 2 Synthesis of the first peptide

[0068] 1) Add NMP (30ml) to the acetalization product (3.4g), DCC (1.2g), HOBt (1.6g) under ice-cooling, electromagnetically stir, and react at room temperature for 1 hour.

[0069] 2) Put the resin (5.00g) in a solid-phase reactor, add dichloromethane / dimethylformamide=1 / 1 30ml solvent, and pass high-purity ammonia gas into it and stir for 60 minutes.

[0070] 3) Add the reaction solution of the acetalization product into the solid phase reactor, ventilate and stir, and react at room temperature for 16 hours.

Embodiment 3

[0071] Example 3: Synthesis of the second peptide

[0072] 1) Press out the reaction solution with gas through the waste liquid outlet, wash with dichloromethane, then add 30 mL of dichloromethane, 1.5 mL of acetic anhydride and 1.5 mL of pyridine to the resin in the solid-phase reactor, and stir at room temperature for 2 hours.

[0073] 2) Press out the reaction solution with gas through the waste liquid outlet, wash with dichloromethane, then add 15 mL each of hexahydropyridine and dimethylformamide, and react at room temperature for 1 hour.

[0074] 3) The reaction solution is pressed out through the waste liquid outlet with gas, cleaned with dichloromethane, then Fmoc-Cys(Trt)-OH (4.34g), HOBt (1.10g), HBTU (3.10g) are added to the In the solid-phase reactor of the reaction resin in the previous step, NMP (30 ml) was added thereto, and nitrogen gas was introduced at the same time, and the reaction was carried out overnight at room temperature for 16 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com