Method for producing rubber coating of protective gloves

A technology for rubber coating and gloves, applied in the field of preparation of rubber coating for labor protection gloves, can solve the problems of unstable injection pressure, uneven rubber thickness, poor adhesion of rubber layer, etc., and achieves low processing cost and saving of rubber raw materials. , The effect of environmental protection and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

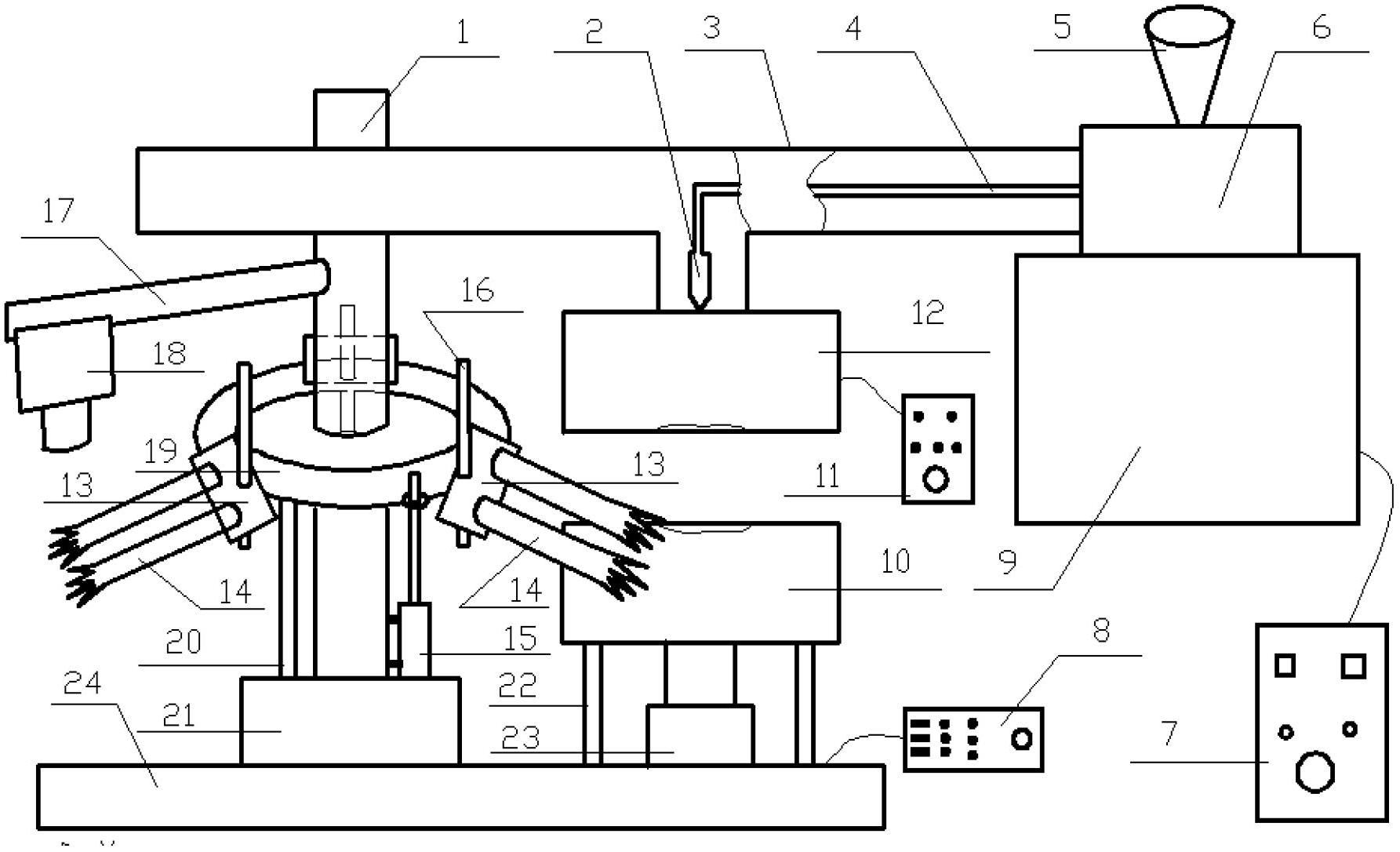

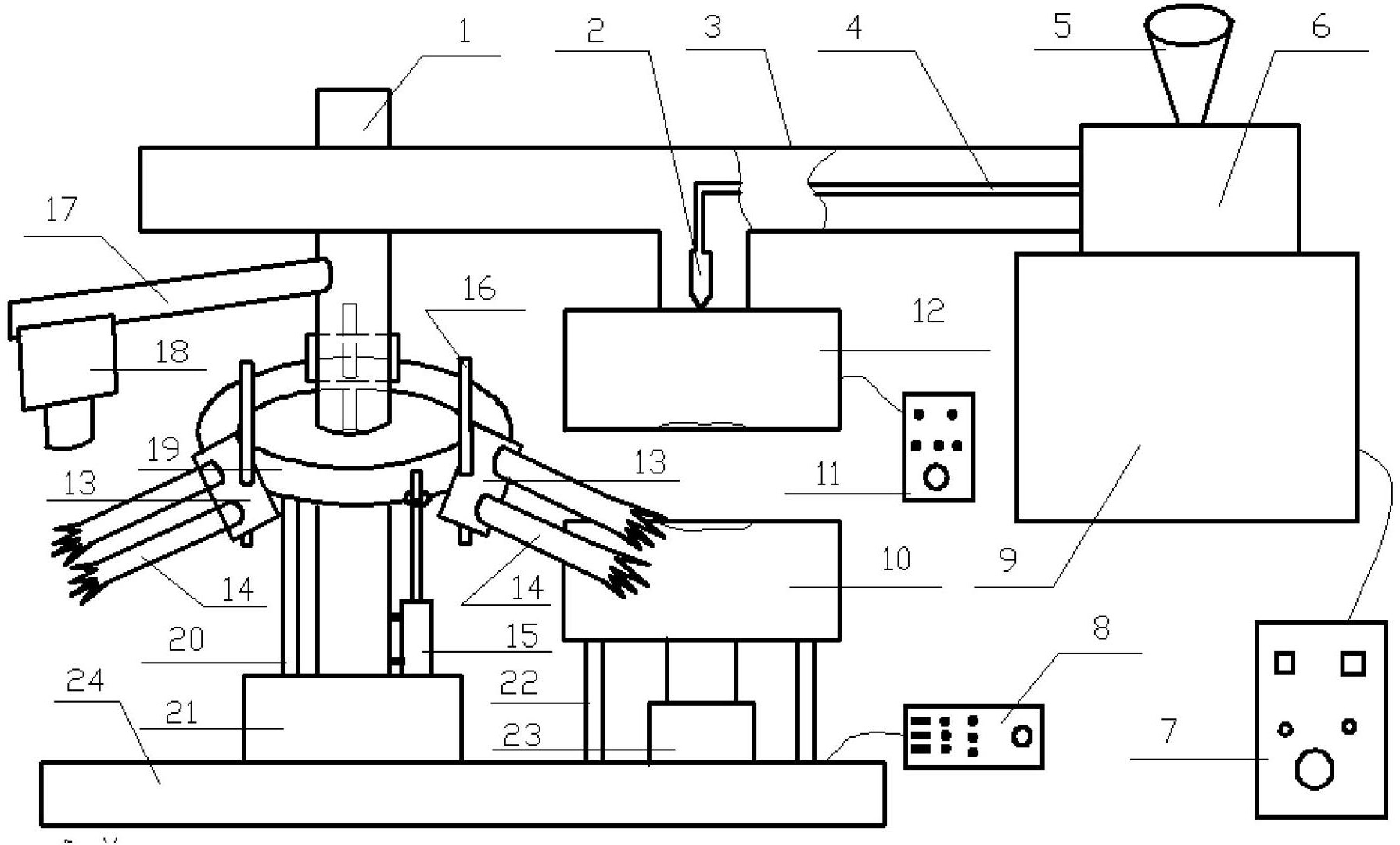

[0009] In this example, a rubber injection molding device is used to prepare rubber coatings on fibrous gloves. First, the fibrous gloves to be coated are wrapped on the hand molds, and then a pair of hand molds that have been wrapped are fixed on the rubber injection coating device. on the slider, and turn the turntable to embed a pair of hand-shaped molds into the inner cavity of the matching upper and lower molds, and keep the fiber surface on the front side of the palm of the hand-shaped mold aligned with the corresponding surface of the inner cavity of the upper and lower molds to form a 0.1-10mm hand cavity Type gap layer, the back side of the hand mold or the back of the hand forms a cavity from the fingertips to the neck of the hand. The thickness of the gap layer gradually decreases to zero, or the surface of the glove fiber on the hand mold is aligned with the corresponding surface of the inner cavity of the upper and lower molds. 0.1 ~ 10mm back of the hand cavity ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com