A kind of ammonium polyphosphate with high degree of polymerization and preparation method thereof

A technology with high polymerization degree of ammonium polyphosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low polymerization degree of ammonium polyphosphate, achieve high product value, simple process, and concise process principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Shock wave synthesis of high degree of polymerization ammonium polyphosphate, the specific steps are as follows:

[0030] (1) Drying of raw materials: The ammonium polyphosphate powder with a degree of polymerization of 10 is dried in an infrared oven.

[0031] (2) Dry pressing: pass the dried ammonium phosphate powder with a low degree of polymerization through a steel mold, and press it under a pressure of 10 MPa to form a cylindrical blank film.

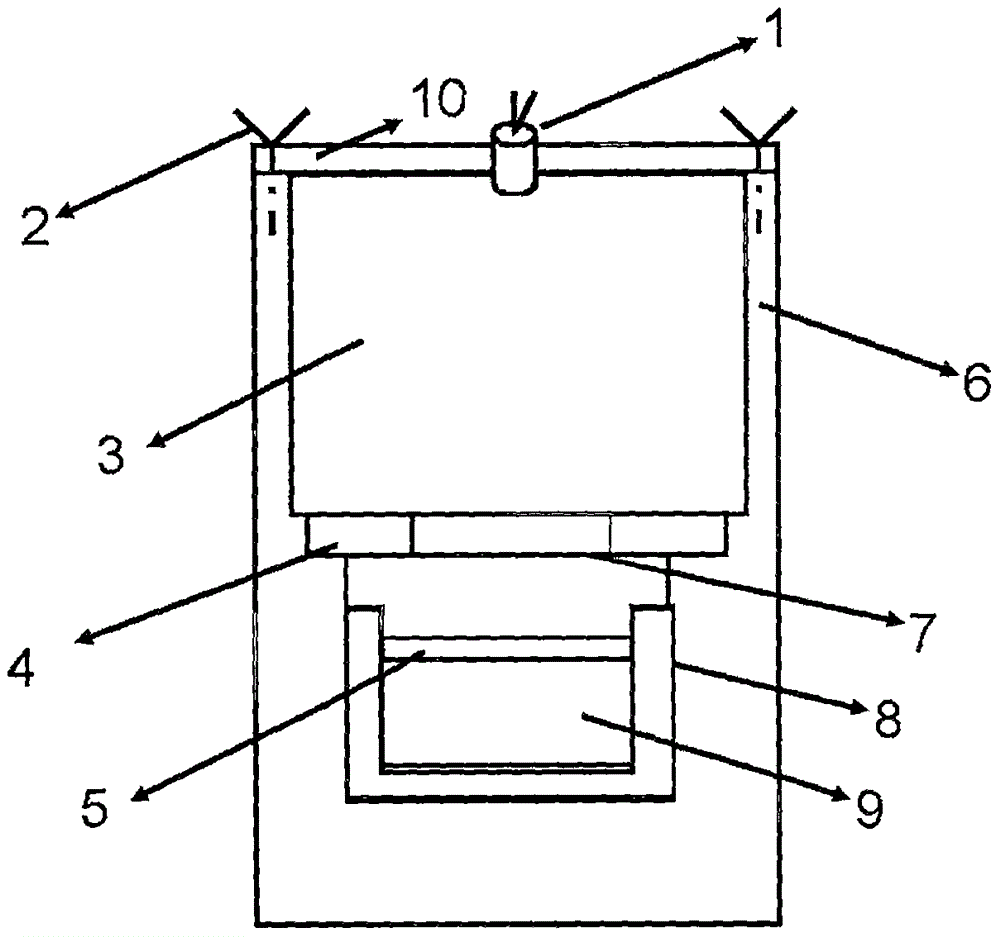

[0032] (3) Synthetic cavity assembly (for the device see figure 1 ): put the blank mold 9 together with the pyrophyllite mold 8 into the bottom of the cavity 3, put the pressure transmission backing plate 5 on the blank mold 9, cover the partition plate 4 and the parallel flying pieces 7, and fill the cavity 3 with explosives, Explosive filling quantity is 1kg, covers cover plate 10 and tightens screw 2, loads onto electric detonator 1.

[0033] (4) Shock wave synthesis: connect the power supply at both ends of the electr...

Embodiment 2

[0039] Shock wave synthesis of high degree of polymerization ammonium polyphosphate, the specific steps are as follows:

[0040] (1) Raw material drying: the ammonium polyphosphate powder with a degree of polymerization of 10 is dried in a vacuum oven.

[0041] (2) Dry pressing: pass the dried ammonium phosphate powder with a low degree of polymerization through a steel mold, and press it under a pressure of 20 MPa to form a square blank film.

[0042] (3) Synthetic cavity assembly (for the device see figure 1 ): put the blank mold 9 together with the pyrophyllite mold 8 into the bottom of the cavity 3, put the pressure transmission backing plate 5 on the blank mold 9, cover the partition plate 4 and the parallel flying pieces 7, and fill the cavity 3 with explosives, Explosive filling quantity is 5kg, covers cover plate 10 and tightens screw 2, loads onto electric detonator 1.

[0043] (4) Shock wave synthesis: connect the power supply at both ends of the electric detonator...

Embodiment 3

[0049] Shock wave synthesis of high degree of polymerization ammonium polyphosphate, the specific steps are as follows:

[0050] (1) Drying of raw materials: The ammonium polyphosphate powder with a degree of polymerization of 50 is dried in an ordinary oven.

[0051] (2) Dry pressing: pass the dried ammonium phosphate powder with a low degree of polymerization through a steel mold, and press it under a pressure of 20 MPa to form a cuboid blank film.

[0052] (3) Synthetic cavity assembly (for the device see figure 1 ): put the blank mold 9 together with the pyrophyllite mold 8 into the bottom of the cavity 3, put the pressure transmission backing plate 5 on the blank mold 9, cover the partition plate 4 and the parallel flying pieces 7, and fill the cavity 3 with explosives, Explosive filling quantity is 5kg, covers cover plate 10 and tightens screw 2, loads onto electric detonator 1.

[0053] (4) Shock wave synthesis: connect the power supply at both ends of the electric de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com