Stainless steel pickling sludge treatment method

A technology of pickling sludge and treatment method, which is applied in chemical instruments and methods, wet separation, photographic technology, etc., can solve the problems of large amount of stainless steel pickling sludge and high disposal costs, and achieve economic and social benefits. The effect of benign development, mature technology and simple process principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

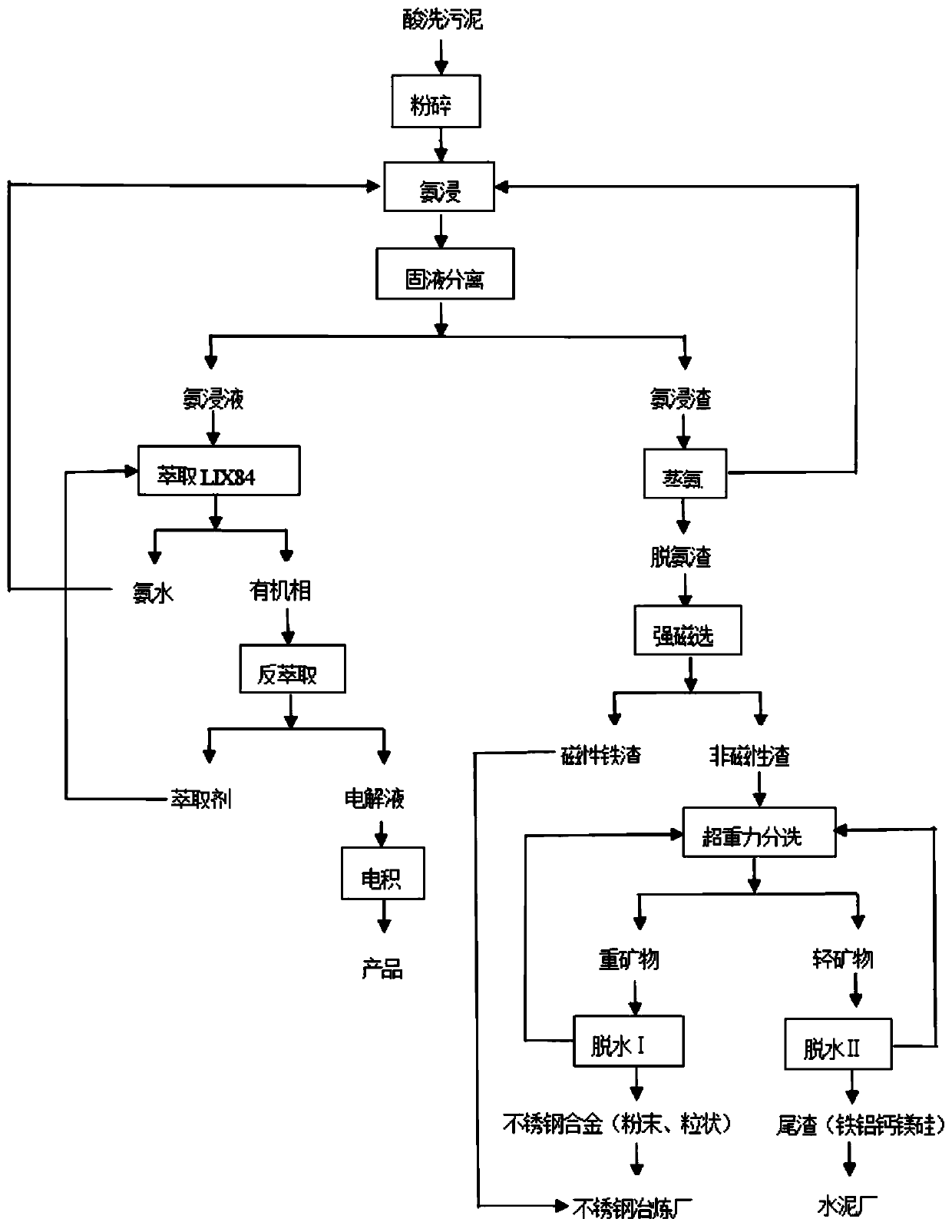

Method used

Image

Examples

Embodiment 1

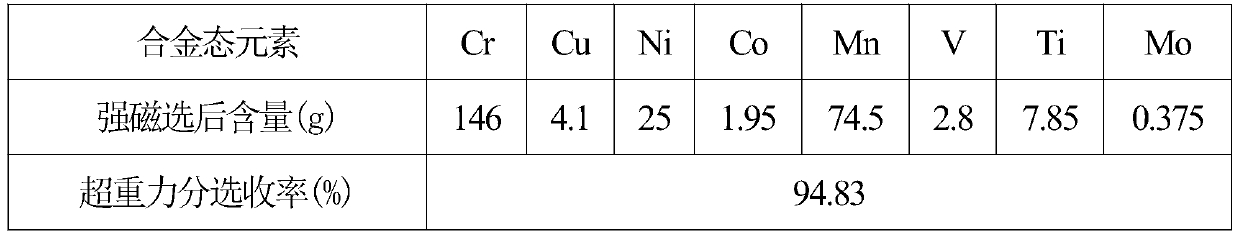

[0049] The present embodiment is taken from a stainless steel factory pickling sludge, analyzes the existing form of its heavy metal elements, and obtains the heavy metal element existing form table such as Table 1

[0050] Table 1 Existing forms of heavy metal elements in pickling sludge

[0051] form of existence iron chromium nickel copper cobalt molybdenum vanadium manganese titanium Hydroxide state Fe(OH) 3

Cr(OH) 3

Ni(OH) 2

Cu(OH) 2

Co(OH) 2

/ / Mn(OH) 2

/ Water-soluble ionic state FeO(OH) nH 2 o

[Cr(H 2 O) 6 ] 3+

/ / / / / / / alloy state alloy iron Alloy chrome Alloy Nickel Alloy copper Alloy cobalt Alloy molybdenum Alloy vanadium Alloy Manganese Alloy titanium

[0052] It can be seen from the above table that heavy metals in pickling sludge exist in three forms: water-soluble ionic state, aqueous hydroxide state and alloy state. Selective leac...

Embodiment 2

[0079] The stainless steel pickling sludge processing method of the present embodiment comprises the steps:

[0080] S1 crushing: drying, dehydrating and crushing the acid-washed sludge to below 80 mesh as a sample for later use;

[0081] Specifically: Take 10Kg of pickling sludge from the Southwest Stainless Steel Plant, dry and pulverize it to below -80 mesh (<0.178mm), mix it evenly and use it as a sample for later use;

[0082] S2 ammonia immersion: put the sample obtained in step S1 into the ammonia immersion tank and add ammonia water for immersion, and obtain ammonia leaching residue and ammonia leaching solution after solid-liquid separation:

[0083] Specifically: take 5Kg of the sample obtained in step S1 and put it into an ammonia immersion tank, then add 5L of ammonia water with a mass percentage concentration of 20%, soak for one day at room temperature, and separate the solid and liquid the next day to obtain 5.8Kg of ammonia leaching residue and ammonia leaching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com