Preparation method for cobalt hydroxide film with nano-structure

A technology of cobalt hydroxide and nanostructure, applied in the field of nanomaterials, can solve the problems of uneven size, uncontrollable nano-Co particle size, poor flexibility, etc., and achieve the effects of short cycle, simple and easy operation of the preparation process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Use the glass slide as the substrate to ultrasonically wash each of nitric acid and ethanol for 30 minutes, rinse with distilled water, dry naturally at room temperature, and set aside;

[0028] 2) The solid Co(SO 4 ) 2 ·7H 2 O is dissolved in 200ml of water, and the molar concentration of Co(II) is obtained as Co(SO 4 ) 2 aqueous solution;

[0029] 3) To Co(SO 4 ) 2 Adding mass concentration to the aqueous solution is 40% hydrofluoric acid to adjust the atomic ratio of F and Co(II) in the solution to be 3:1;

[0030] 4) Slowly add ammonia water with a mass concentration of 35% to the mixed solution in step 3), and adjust the pH value of the solution to 8.9;

[0031] 5) Put the glass slide pretreated in step 1) vertically into step 4) to obtain the solution, and then place the reaction vessel in a water bath at 60° C. for 4 hours of standing reaction;

[0032] 6) Take out the glass slide covered with film, put it into distilled water and ultrasonically wash f...

Embodiment 2

[0035] 1) with embodiment 1 step 1);

[0036] 2) with embodiment 1 step 2);

[0037] 3) To Co(SO 4 ) 2 Adding mass concentration to the aqueous solution is 40% hydrofluoric acid to adjust the atomic ratio of F and Co(II) in the solution to be 9:1;

[0038] 4) with embodiment 1 step 4);

[0039] 5) with embodiment 1 step 5);

[0040] 6) Same as step 6) of Example 1.

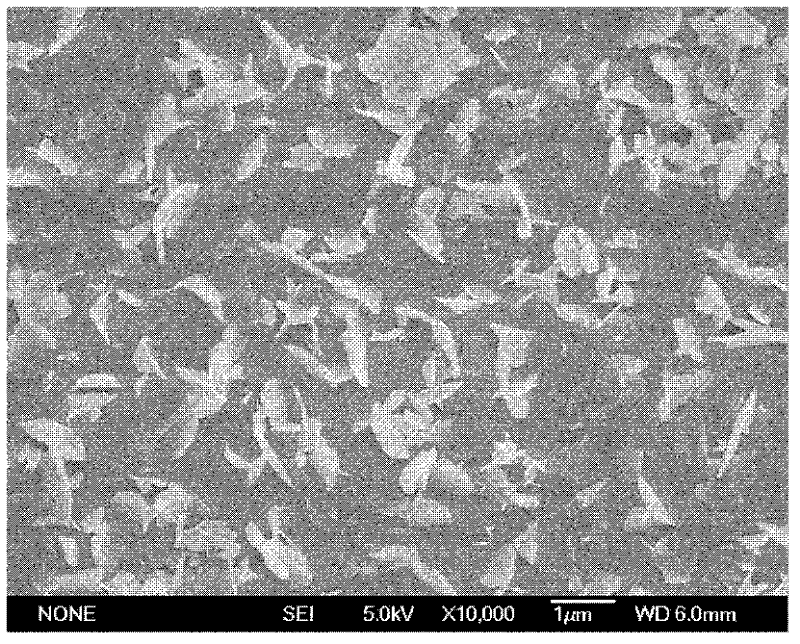

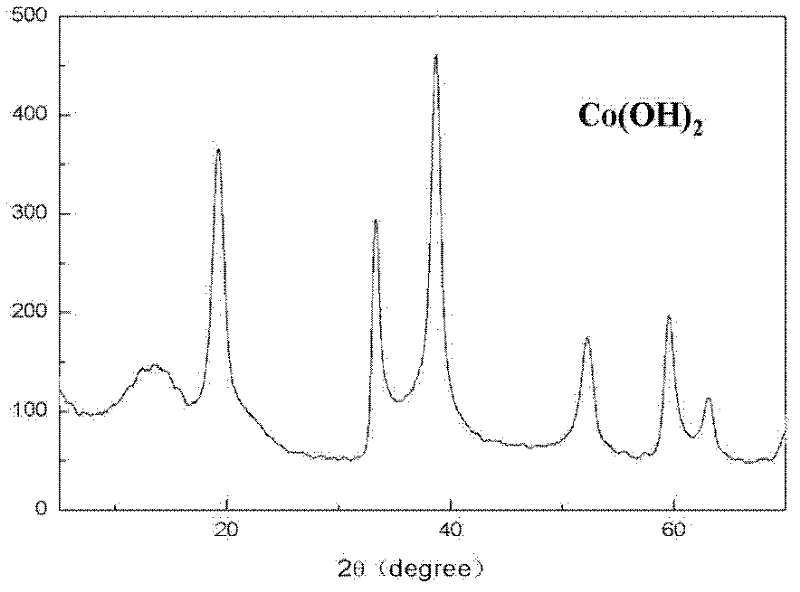

[0041] From image 3 It can be seen that the obtained Co(OH) 2 The film is composed of flake-like flakes and round particles, the round particles are dispersed among the flake-like particles, and the size is within 0.5 μm. The measured film thickness is about 103 nm. X-ray diffraction proves that the film is β-Co(OH) 2 type.

Embodiment 3

[0043] 1) with embodiment 1 step 1);

[0044] 2) with embodiment 1 step 2);

[0045] 3) To Co(SO 4 ) 2 Adding mass concentration to the aqueous solution is 40% hydrofluoric acid to adjust the atomic ratio of F and Co(II) in the solution to be 6:1;

[0046] 4) with embodiment 1 step 4);

[0047] 5) with embodiment 1 step 5);

[0048] 6) Same as step 6) of Example 1.

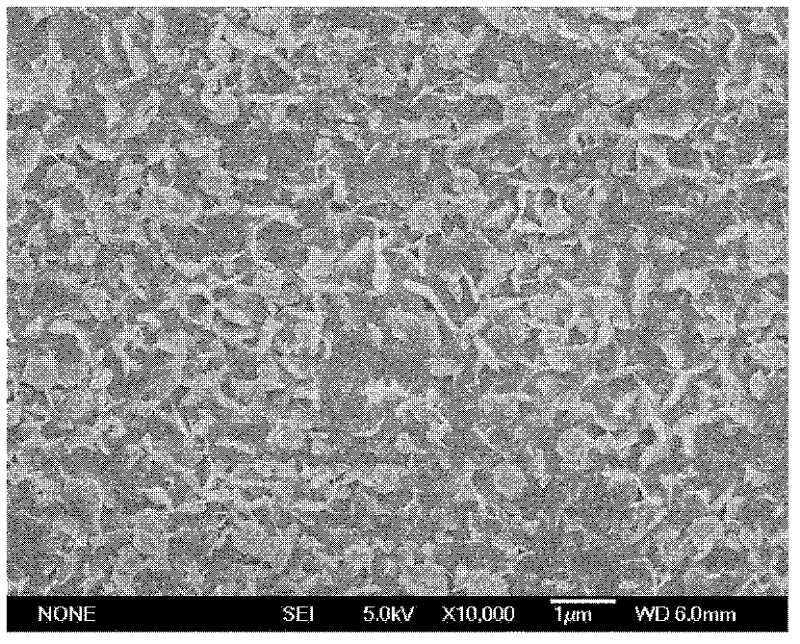

[0049] From Figure 4 It can be seen that the obtained Co(OH) 2 The film is composed of flake-like particles, the size of the flake-like particles is relatively large, the connection between the layers is tight, and the surface of the film is dense. From Figure 5 It can be seen that the film thickness measured by the NV50005032 surface roughness measuring instrument is about 673 nm. X-ray diffraction proves that the obtained film is β-Co(OH) 2 type.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com