Refined copper slag wet treatment process

A technology for wet processing and refining copper, which is applied in the direction of photographic process, photographic auxiliary process, and improvement of process efficiency. low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

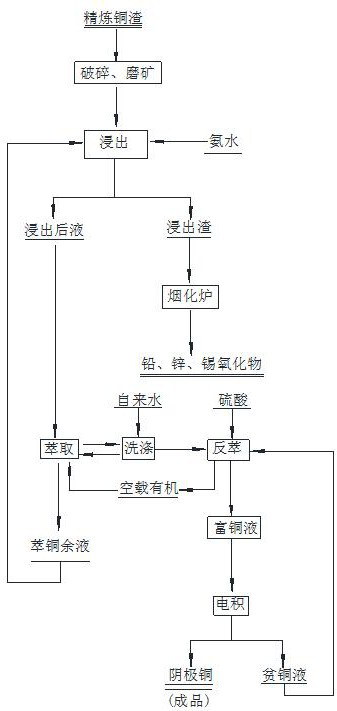

[0027] Such as figure 1 Shown, a kind of refining copper slag wet treatment process comprises the following steps:

[0028] Step S1, coarsely crushing the refined copper slag, finely crushing it, and ball milling the refined copper slag to a particle size of -80 to -200 mesh;

[0029] Step S2, leaching the ground refined copper slag and the ammonia water-ammonium sulfate mixture at normal temperature and pressure, performing solid-liquid separation after leaching, and obtaining a cuproammonia complex solution and a solution containing nickel, lead, iron, and tin after solid-liquid separation. Polymetallic leaching residue;

[0030] Step S3, the cuproammonia complex solution is extracted with the copper extractant, the copper in the solution is enriched into the extractant after extraction, and the extractant is back-extracted by electrowinning copper-poor solution or sulfuric acid to obtain a copper-rich solution;

[0031] Step S4, the copper-rich solution enters the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com