Method for preparing nano black carbon passivator for repairing heavy metal contaminated soil

A technology for polluted soil and heavy metals, which is applied in the restoration of polluted soil, chemical instruments and methods, and other chemical processes. It can solve the problem of high production cost of modified wastewater passivator, damage to microporous structure, and influence on popularization and application. and other issues, to achieve the effect of wide application range, friendly production environment and simple process principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the screening of oxidizing agent

[0027] This embodiment first selects five kinds of oxidizing agents (see Table 1 for the concentration of the oxidizing agent) composed of concentrated nitric acid, sulfuric acid, potassium permanganate, sulfuric acid+potassium permanganate and nitric acid+potassium permanganate as a comparison, and then weigh 5 Groups of nanometer black carbon, each group of 20g in 250ml Erlenmeyer flasks, add 200ml of oxidant to each bottle, put them in a fume hood for 24 hours, and then carry out the oxidation reaction. Follow the process steps below to prepare five kinds of Modified nano black carbon passivator under oxidant oxidation conditions; then weigh several parts of 0.1g modified nano black carbon respectively, place them in centrifuge tubes respectively, add 20ml of Cu(NO 3 ) 2 Solutions, the concentrations of which are 30mg / L, 50mg / L, 70mg / L, 100mg / L, 130mg / L, 160mg / L, 200mg / L, were shaken at 25°C for 2 hours, and placed in...

Embodiment 2

[0031] Embodiment 2: nitric acid+potassium permanganate oxidant oxidation process parameter

[0032] (1) Determination of oxidant concentration

[0033] 20%HNO 3 Respectively with 0.05~0.20mol / L KMnO 4 Solution is made a series of nitric acid-potassium permanganate mixed oxidant; The following is operated by technological process steps, respectively prepares the modified nano-black carbon passivator under different concentration nitric acid-potassium permanganate mixed oxidant oxidation conditions; By table 2 It can be seen that when the concentration of potassium permanganate is 0.10mol / L, the Cu 2+ The maximum adsorption capacity;

[0034] Table 2 Effect of potassium permanganate concentration on the adsorption capacity of modified nano black carbon for heavy metals

[0035] Potassium permanganate concentration / (mol / L)

Adsorption amount of Cu (mg / g)

0.05

13.51

0.10

15.85

0.20

15.13

[0036] (2) Determination of oxidatio...

Embodiment 3

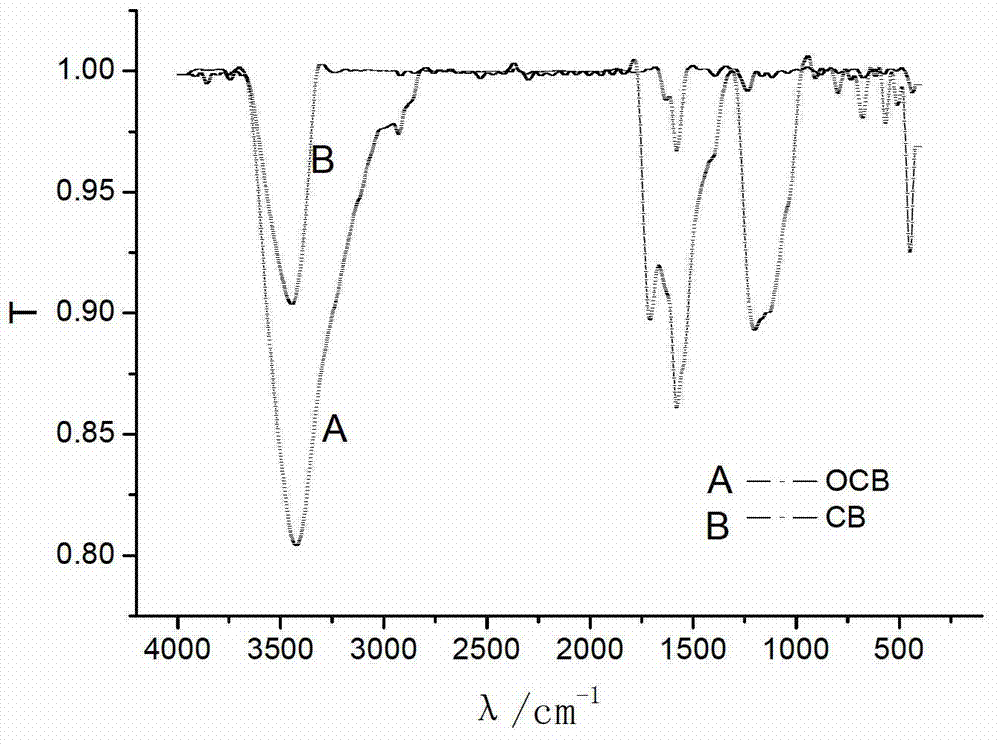

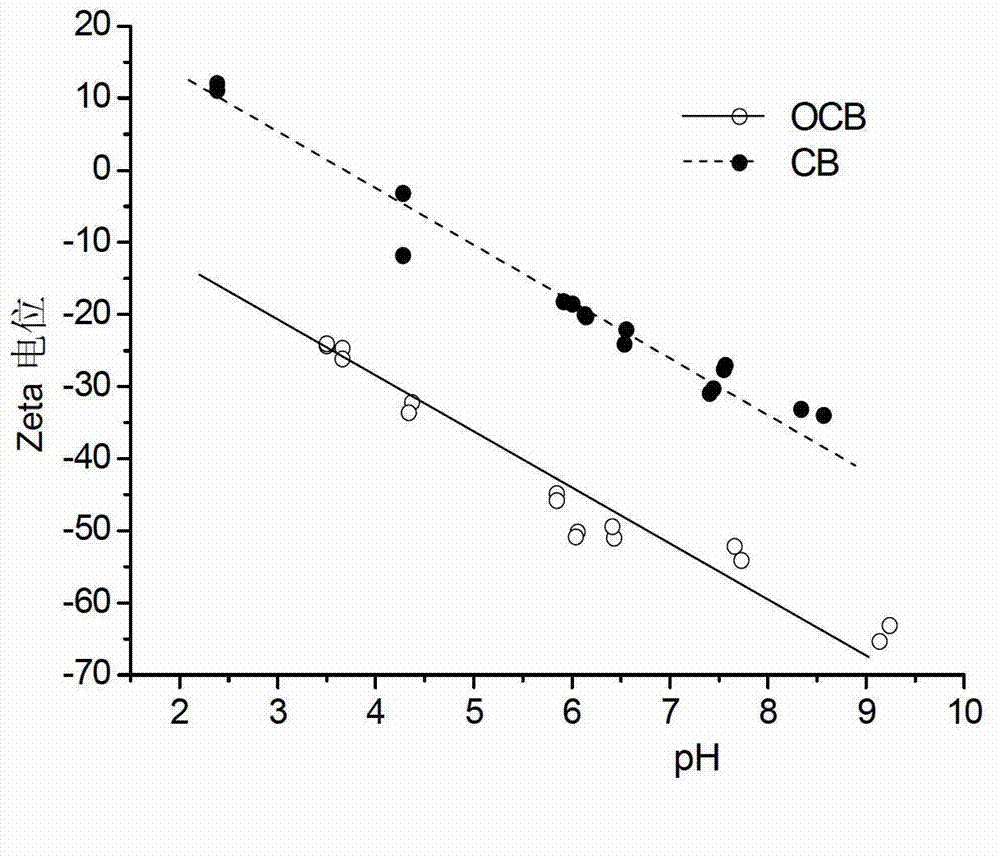

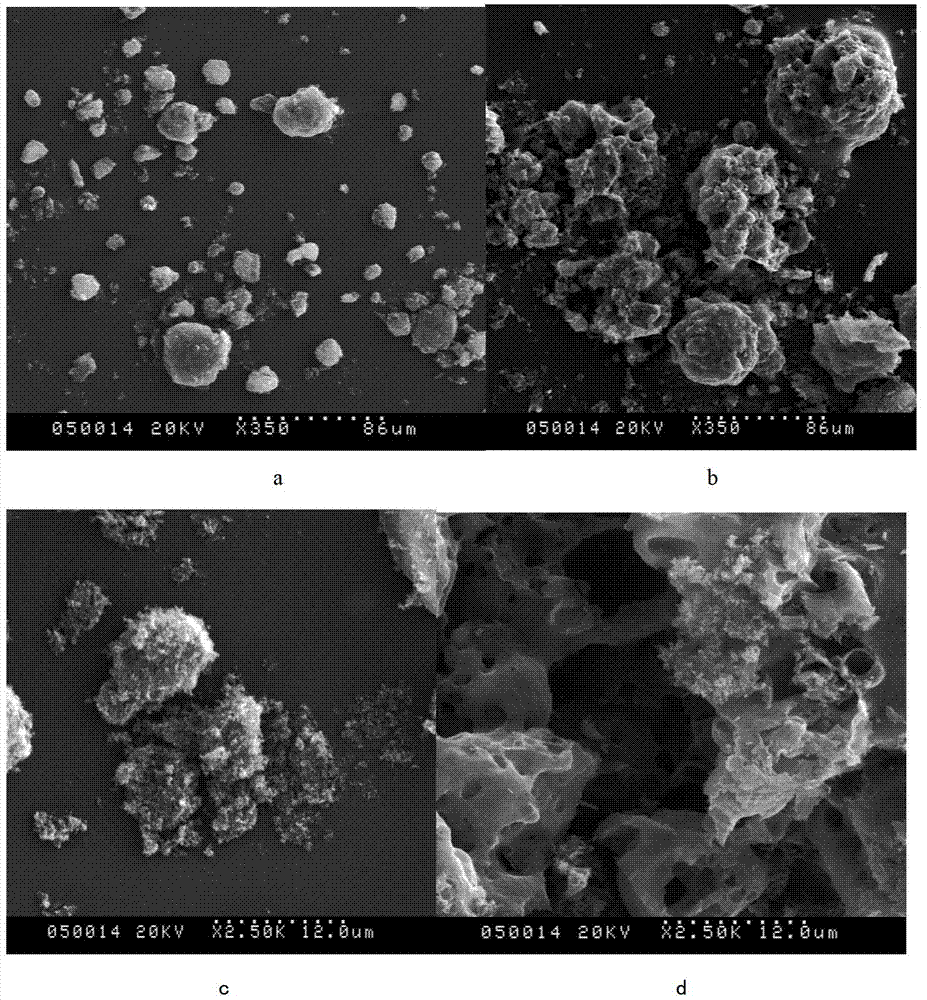

[0048] Embodiment 3: Modified nano black carbon passivator morphology structure and surface characteristics

[0049] (1) Oxygen-containing functional groups on the surface increase after oxidation modification

[0050] figure 1 It is the infrared spectrogram of nano black carbon passivator before and after modification (CB and OCB), the peak position before modification (CB) is at 1619cm -1 and 3450cm -1 , respectively C=C stretching vibration and O-H stretching vibration; In addition to the increase in the area of these two peaks in the infrared spectrum after modification (OCB), a new 1244.0cm -1 , 1721.6cm -1 , 447.3cm -1 The equal peaks are the stretching vibration of C-O, the stretching vibration of C=O and the bending vibration of CNO group respectively; it shows that after CB is oxidized and modified, in addition to the increase of C=C and O-H functional groups on the surface of OCB compared with CB, there are also new C-O, C=O and CNO functional groups are remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com