Adjustable frame column formwork back arris system

A frame column and adjustable technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of material waste, time-consuming and labor-intensive, and increased material consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further illustrated below by specific examples.

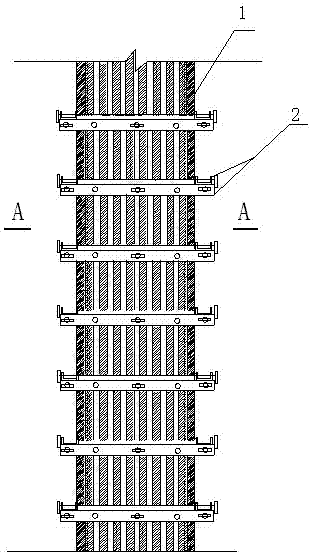

[0026] Such as figure 1 , figure 2 As shown, a method for building an adjustable frame column formwork back corrugated system; it includes the following steps:

[0027] Step 1. Determine the number of turnover sets of black film-coated wood formwork according to the type of frame column;

[0028] Step 2. Determine the size of the channel steel back corrugated plate, the diameter and the number of openings according to the section size and height of the frame column;

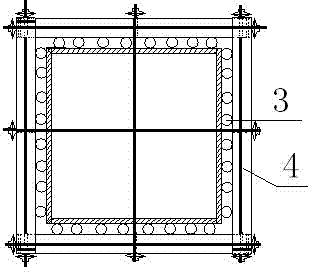

[0029] Step 3. Determine the vertical steel pipe back flute 3 spacing according to the section size of the frame column;

[0030] Step 4. When the size of the column section is less than 800mm, the frame column does not need to be provided with pull screw 4; when the size of the column section is greater than or equal to 800mm, but less than 1500mm, a 16mm diameter channel is installed at 2 places of each transverse channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com