Sealing method after excavation of deep foundation pit downfall pipe well

A technology for downfall pipes and deep foundation pits, which is applied in infrastructure engineering, construction, etc., can solve problems such as inability to form a vacuum and affect the use efficiency of downfall vacuum tube wells, and achieve the effects of easy operation, convenient installation and disassembly, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

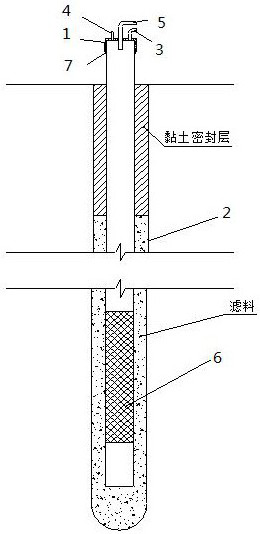

[0011] Example 1, figure 1 Under the condition that the earthwork is not excavated, the well cap is buckled on the downcomer well 6 at this time. The well cap has threading pipe 4, drain pipe 5 and vacuum pipe 3 respectively. The water pump drainage pipe in the tube well and the drainage pipe outside the well, the vacuum tube is connected to the vacuum pump outside the well, and the plastic film 7 is wound and sealed between the well cap and the downfall tube well, and the wrapped film will be automatically adsorbed on the outer wall of the downwater well and the outer wall of the well cap Play a sealing role.

Embodiment 2

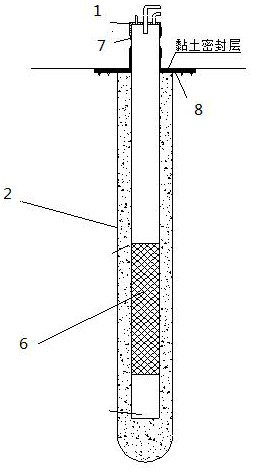

[0012] Example 2, figure 2 After excavating the foundation pit, dig through the clay sealing layer on the upper part of the filter section. At this time, the inside of the dewatering well is connected with the outside atmosphere through the permeable filter material, and a vacuum cannot be formed in the dewatering well. At this time, the well cap is buckled in according to working condition 1 On the downcomer well, dig out a layer of the filter section at the bottom of the foundation pit and put on the filter section sealing gland and seal it with clay. The upper part of the filter section sealing gland is wrapped with a plastic film to seal the downwater tube well. The vacuum downwater tube well is in the case of working condition 2 It can ensure that the well is sealed to form a vacuum, and give full play to the effectiveness of the vacuum downwater tube well. Working condition 2 can be used repeatedly in the case of multi-layer excavation, so that the deep foundation pit do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com