Cleaning and dehydrating method of toluenediamine

A toluene diamine, clean technology, applied in the field of cleaning and dehydration of toluene diamine, can solve the problems of increasing the difficulty and cost of wastewater treatment, increasing the load of vacuum equipment, and exceeding the standard of TDA water content, so as to save resources, reduce load and reduce COD The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

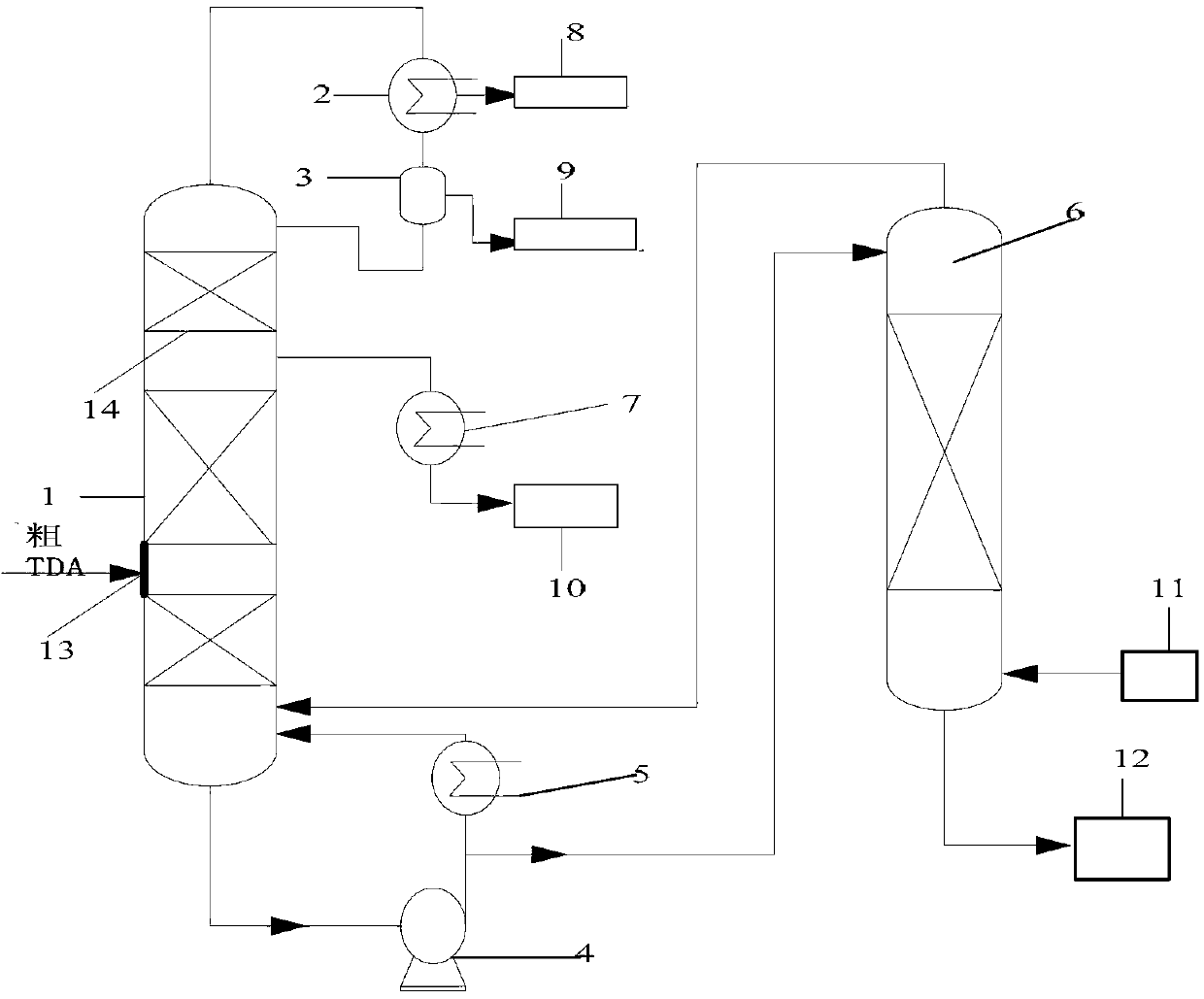

[0008] Further description will be given below through the embodiments and in conjunction with the accompanying drawings.

[0009] In this embodiment, a double-tower dehydration device composed of an atmospheric rectification tower and a nitrogen stripping tower and its process are used to dehydrate TDA. The TDA inlet 13 enters the lower part of the dehydration tower 1, the top gas phase of the dehydration tower 1 enters the tower top condenser 2 for condensation, and the condensed liquid phase enters the reflux tank 3, and the low boiling point components enter the tail gas destruction system of the peripheral equipment along with the non-condensable gas 8. An ordinary glass liquid level gauge is installed on the reflux tank 3, and total reflux is usually used to facilitate the enrichment of low boiling point components. The liquid phase is collected in the light components storage tank 9 as a by-product; the side line part of the dehydration tower 1 continuously extracts the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com