Labor-protecting gloves with rubber and plastic material protective coatings

A technology of labor protection gloves and protective layers, applied in gloves, protective clothing, clothing, etc., can solve the problems of short service life of gloves, inconsistent product specifications, poor environmental performance, etc., and achieve low processing costs, high product quality, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

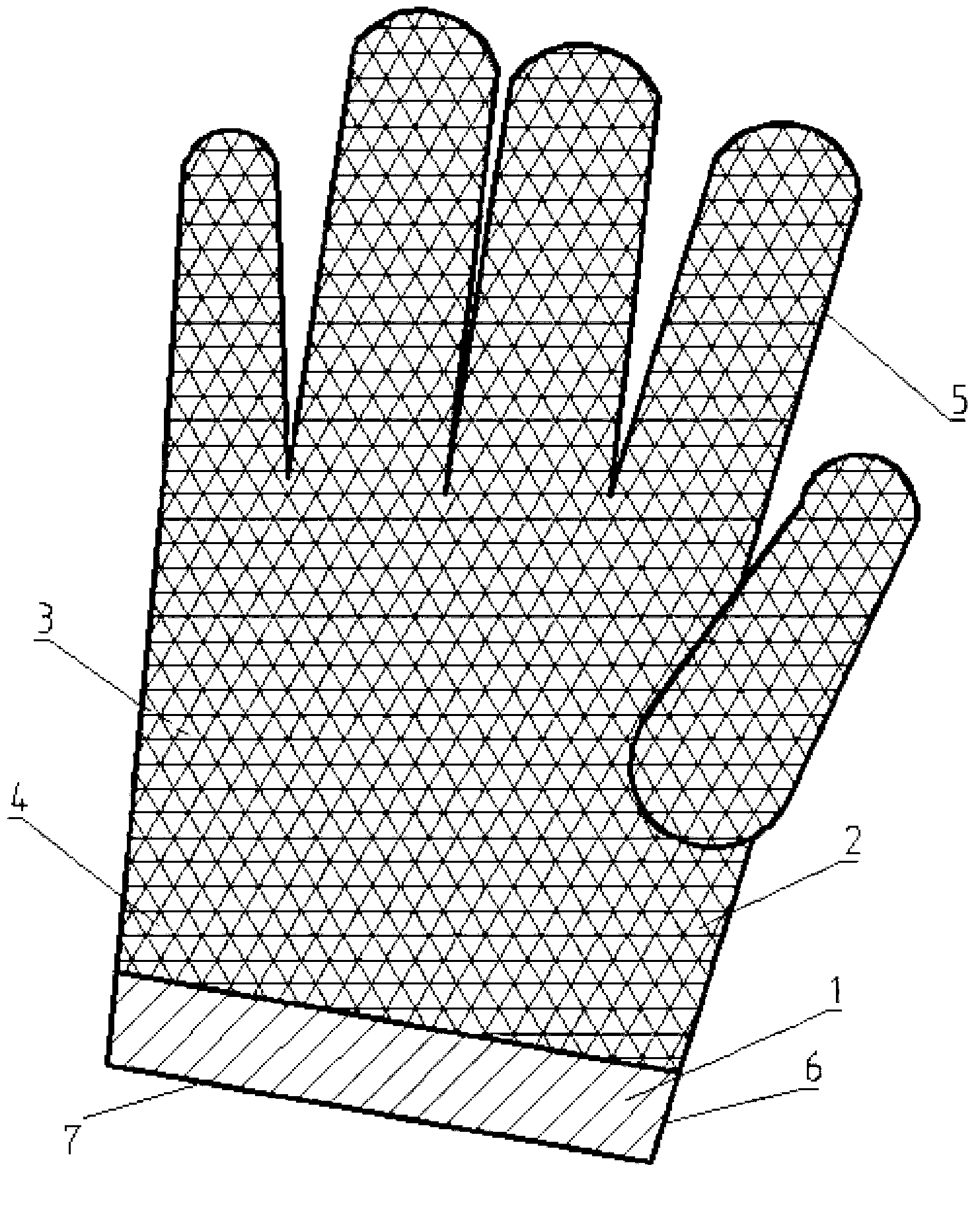

[0010] The main structure of the present embodiment comprises a fiber glove body 1, a protective layer 4, a glove core surface 2, a glove back 3, a butt edge 5, an area without a protective layer 6 and a glove edge 7; The glove body 1 is divided into two structural parts, the glove core surface 2 and the glove back surface 3. The junction between the glove core surface 2 and the glove back surface 3 without obvious boundaries is the butt joint edge 5, and the glove edge 7 of the fiber glove body 1 is left with 0 -20mm non-protective layer area 6, no protective layer coated with protective material on the non-protective layer area 6; the glove core surface 2 of the fiber glove body 1 is fully covered with a closed protective layer 4 coated with rubber and plastic materials, fiber gloves The area of the protective layer coated on the back 3 of the glove of the body 1 is 0-100% of the area of the entire back 3 of the glove, that is, the back 3 of the glove is coated with a pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com