Glass waster material fluid transmission system

A technology for fluid transmission and glass waste, which is applied to conveyors, transportation and packaging, and transportation of bulk materials, etc. It can solve the problems of product qualification rate and quality reduction, poor space utilization, and maintenance manpower, etc., to reduce costs. , Simple equipment, simple equipment repair and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

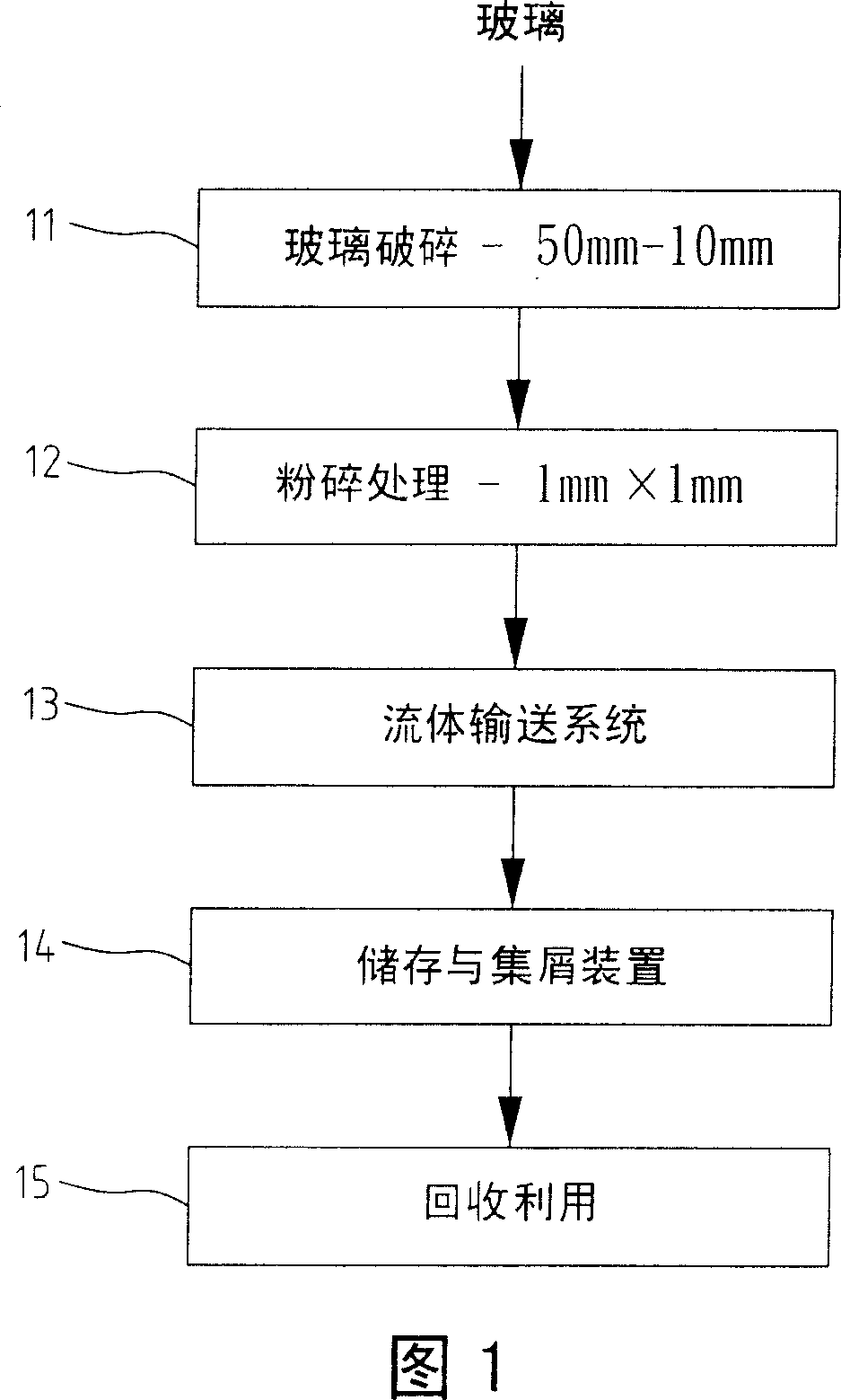

[0041] Figure 1 shows the steps of glass waste treatment. Firstly, the glass waste produced by the photovoltaic power plant is broken into 50mm-10mm particles after glass crushing 11, and then crushed 12 to grind the particles into 1mm×1mm powdered glass waste, which is transported through the fluid delivery system 13 The powdered glass waste is collected in storage and chip collection device 14, and finally utilized on trucks for specific recycling 15.

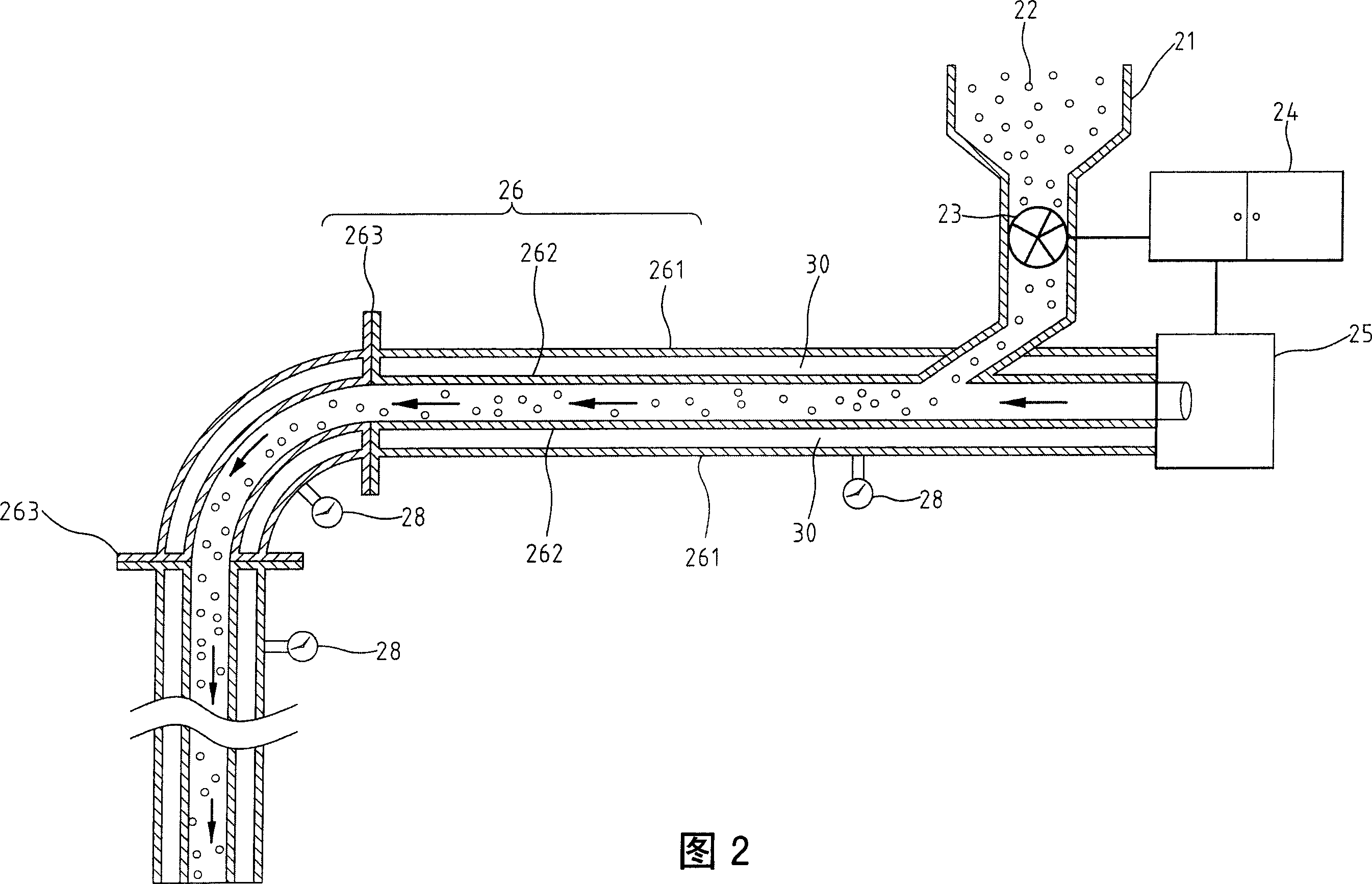

[0042] Figure 2 is a schematic diagram of the fluid transfer system of the present invention. The system includes a storage tank 21 , powdered glass waste 22 , a rotary valve 23 , a feedback control unit 24 , an air conveying power device, and a double-layer conveying pipeline 26 . The airflow conveying power device may be a blower 25 or a vacuuming device. The airflow conveying power device is connected with the double-layer conveying pipeline 26, and is used as a power source for the movement of the powdered glass waste. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com