Skid-mounted type building mud treatment device and process

A construction mud and treatment device technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc. To solve problems such as complex road connection, to achieve the effect of mixing and not easy to settle, realize integrated management and control, and strong mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

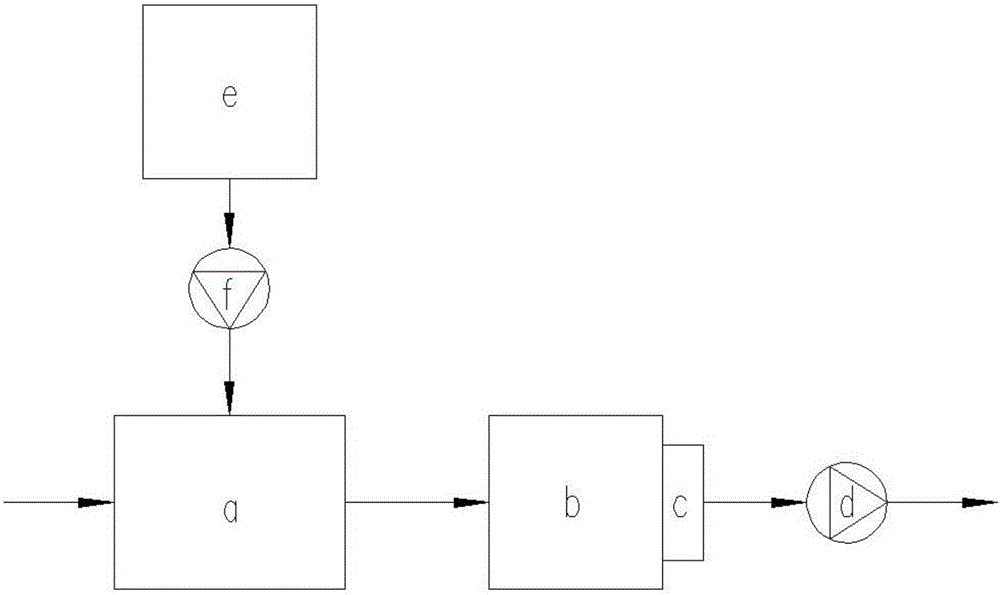

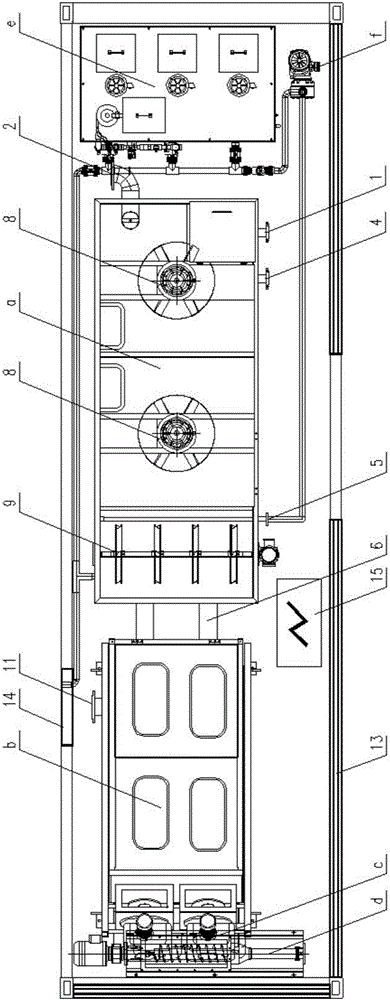

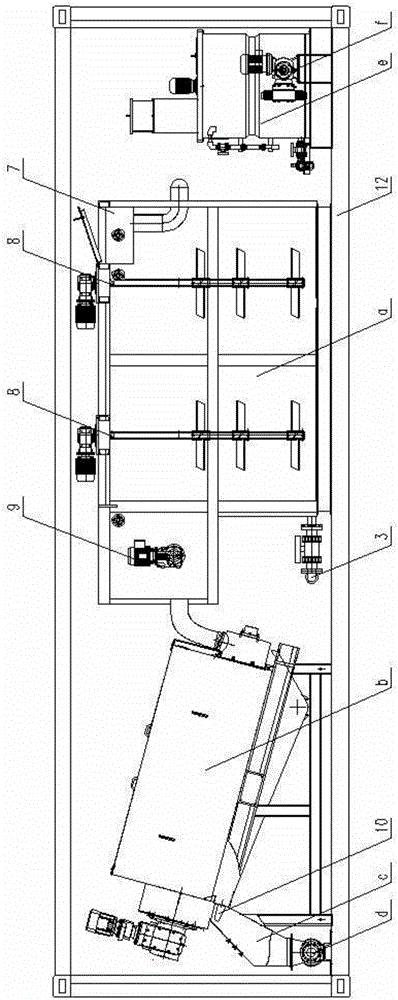

[0041] like figure 1 , figure 2 , image 3 As shown, a skid-mounted construction mud treatment device of the present invention includes a container 12 and a mud homogenizing tank a installed in the container 12, a screw-stacked sludge dewaterer b, a sludge storage tank c, and a sludge conveying Pump d, fully automatic three-compartment medicine preparation system e, medicine dosing pump f and electrical control cabinet 15, etc. The mud homogenizing tank is equipped with a mud inlet, an overflow port, an emptying port, a clean water filling inlet, a medicine feeding port and a mud outlet; the mud homogenizing tank includes two mud homogenizing mixing tanks and a mud medicine mixing tank ; The mud inlet, overflow port, emptying port, and clear water filling inlet of the mud homogenization tank are installed on the homogeneous mixing tank, and the dosing port and mud outlet of the mud homogenizing tank are installed on the mud drug homogenizing mixing tank . The mud inlet 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com