High-power single inversion stud welding machine

A stud welding machine, high-power technology, applied in the direction of converting AC power input to DC power output, output power conversion device, welding equipment, etc., can solve the problem that long welding torch wire cannot be welded, long power cord has high voltage drop, and cannot Complete tasks and other issues to achieve the effect of high anti-interference reliability, reduce failure rate, and improve welding machine power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

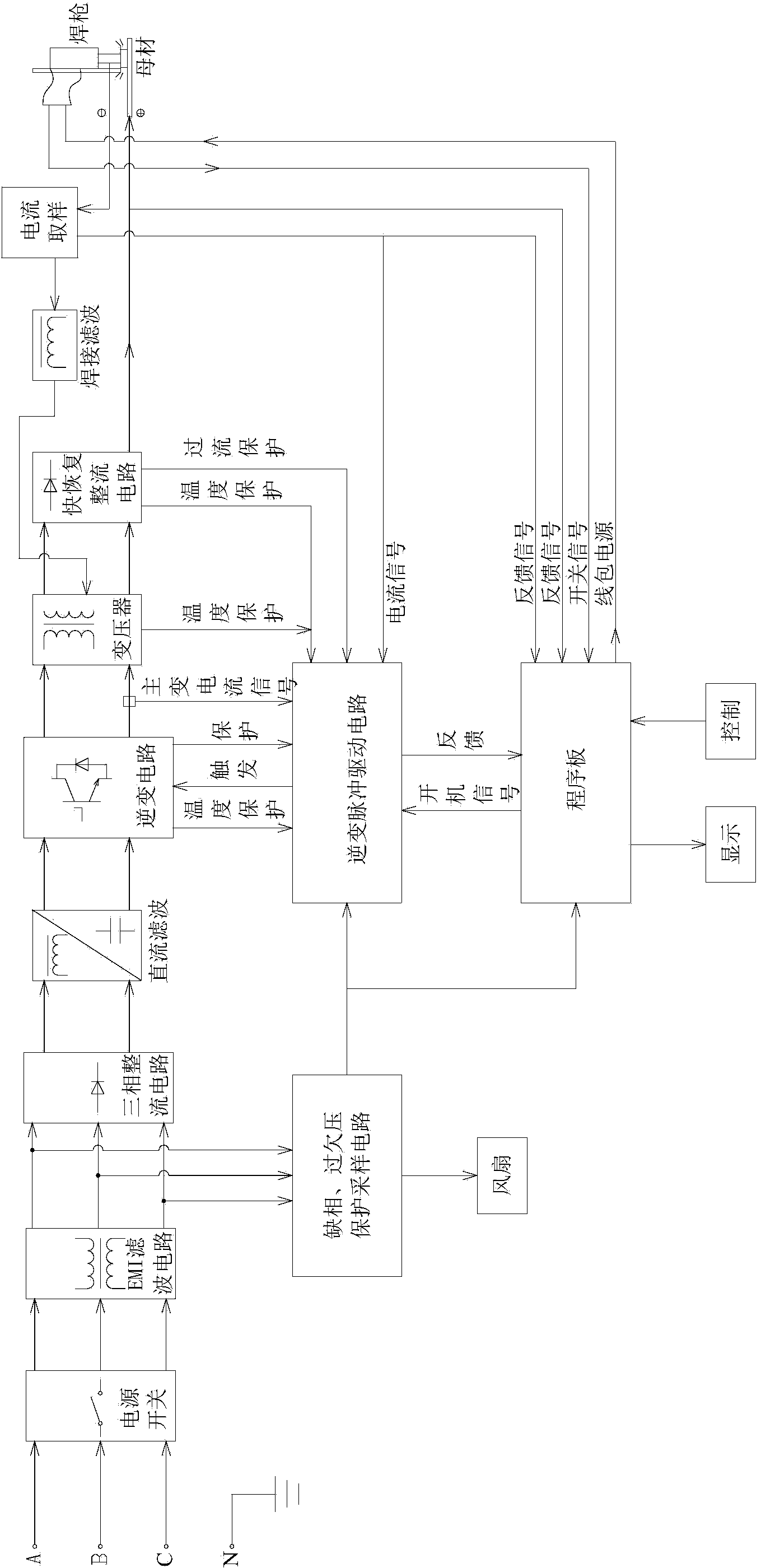

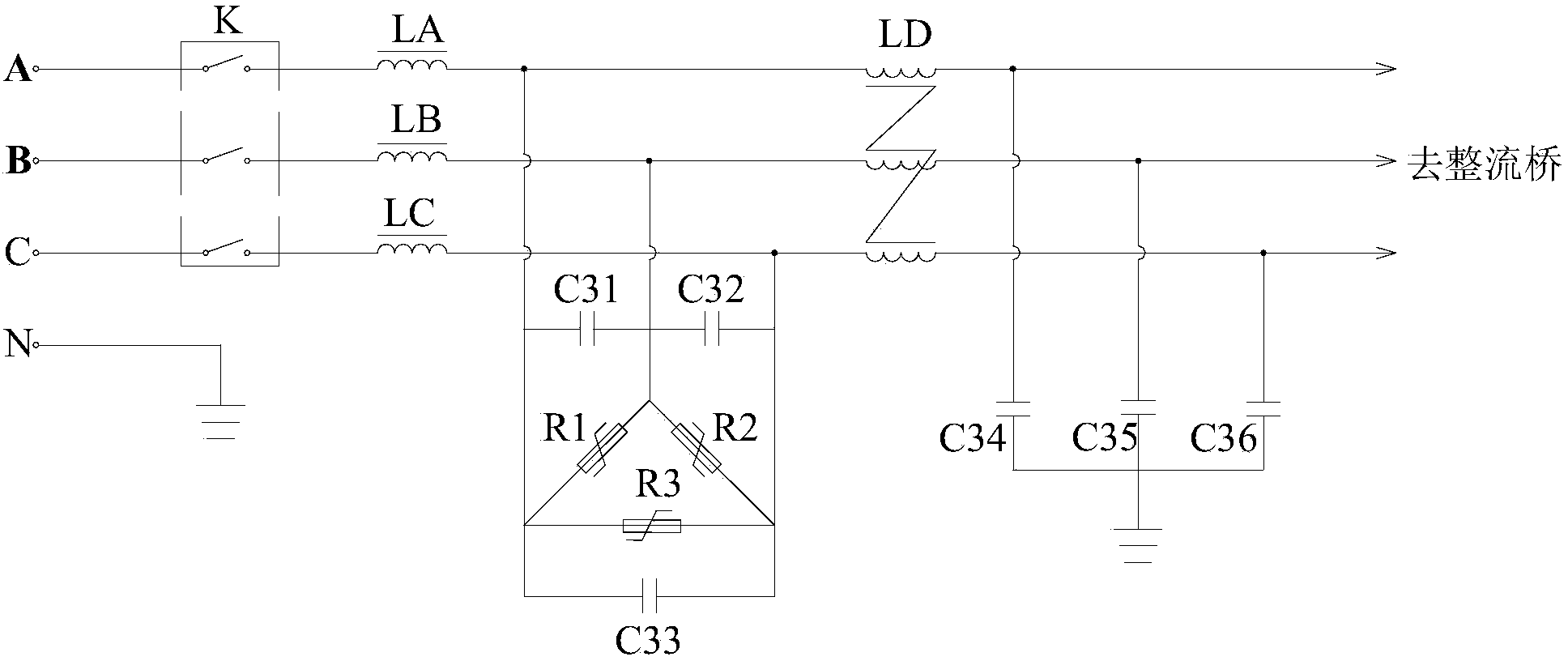

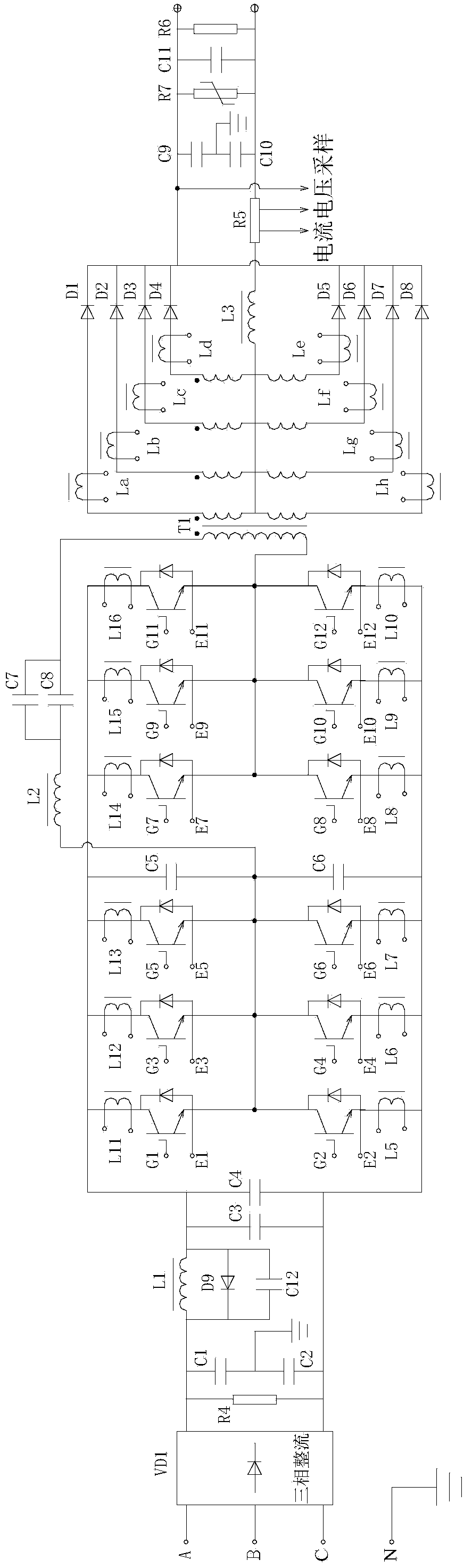

[0050] figure 1 Shown is a circuit schematic diagram of a high-power single-inverter stud welding machine provided in this embodiment, which mainly includes an EMI filter circuit, a three-phase rectifier circuit, an inverter circuit, a high-frequency transformer, and a fast-recovery rectifier circuit connected in sequence , welding torch, base material, in addition, it also includes inverter pulse drive circuit, phase loss, over and under voltage protection sampling circuit, program board, fan, etc. The basic working principle of this stud welding machine is that after the EMI filter circuit filters the three-phase AC, it is converted into DC by a three-phase rectifier circuit, after DC filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com