Porous film and preparation method thereof, and lithium battery

A technology of porous membrane and para-aramid fiber, which is applied in the field of porous membrane, can solve the problems that the content of coating binder cannot be too high, affect the thermal stability of the coated separator, and cannot match the aramid fiber, etc. The effect of good support and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

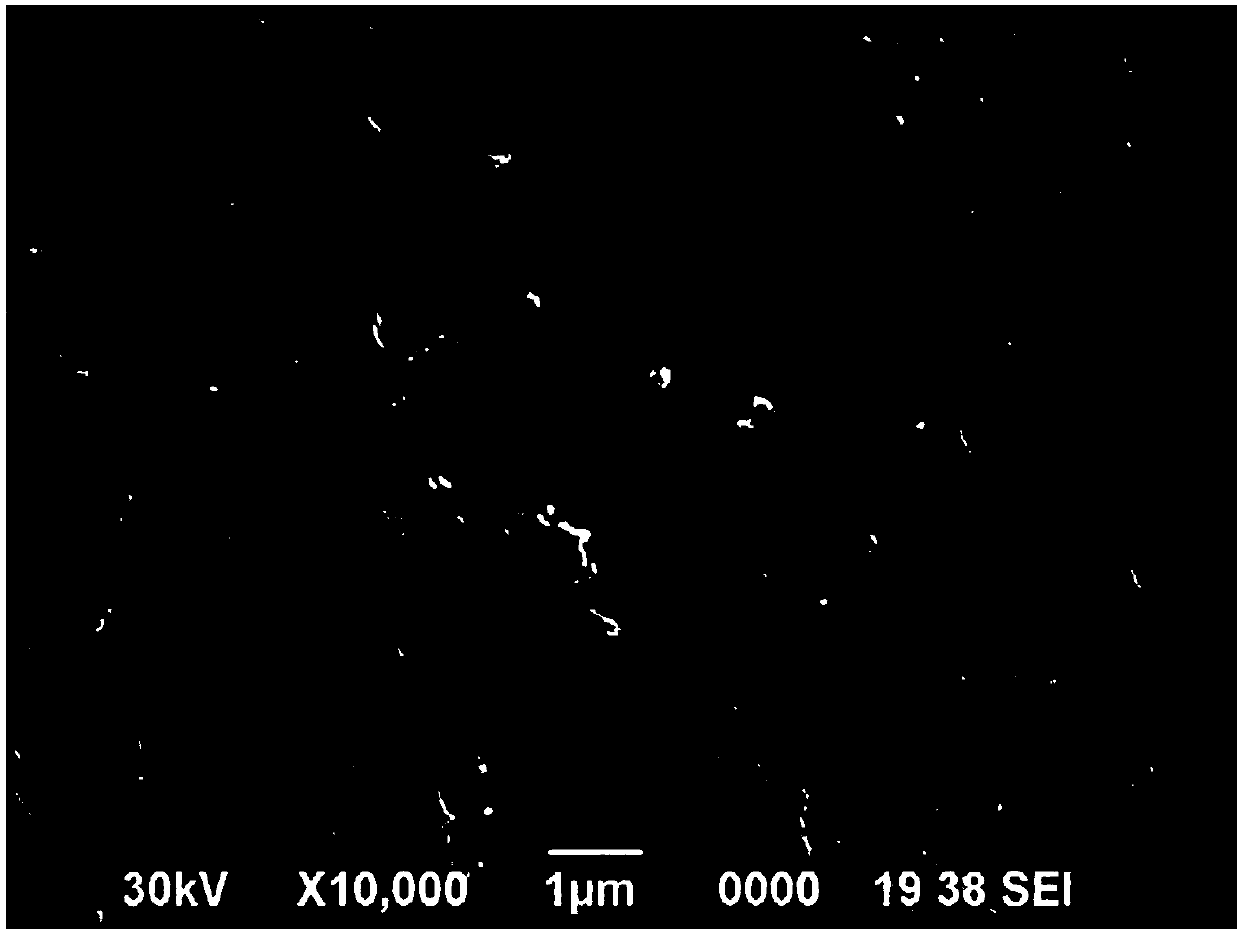

[0088] 100g poly-p-phenylene terephthalamide pulp, 15.0g sodium hydroxide and 500g DMSO are mixed, react 4h at 50 ℃, form poly-p-phenylene terephthalamide nanofiber solution (fiber diameter is 400nm with a length of 2μm). Add 20.0 g of NaH to the poly-p-phenylene terephthalamide nanofiber solution, stir at 70° C. for 1 h to completely react the two, and obtain solution A. With 10g ethylene dichloride and 83g meta-aramid slurry (wherein the meta-aramid slurry is made of meta-aramid, the solvent is DMAC and the cosolvent is CaCl 2 Mix to obtain, the quality of meta-aramid fiber is 25g), join in the above-mentioned solution A, react at 70 ℃ for 2h to form coating slurry, the coating slurry is coated on PE base film (the thickness of base film is 16 μm, porosity 54%) surface film formation; Described film passes through coagulation bath, obtains described porous film; Described coagulation bath is DMAC and H 2 O, wherein the mass ratio of DMAC to water is 3:7, the temperature of...

Embodiment 2

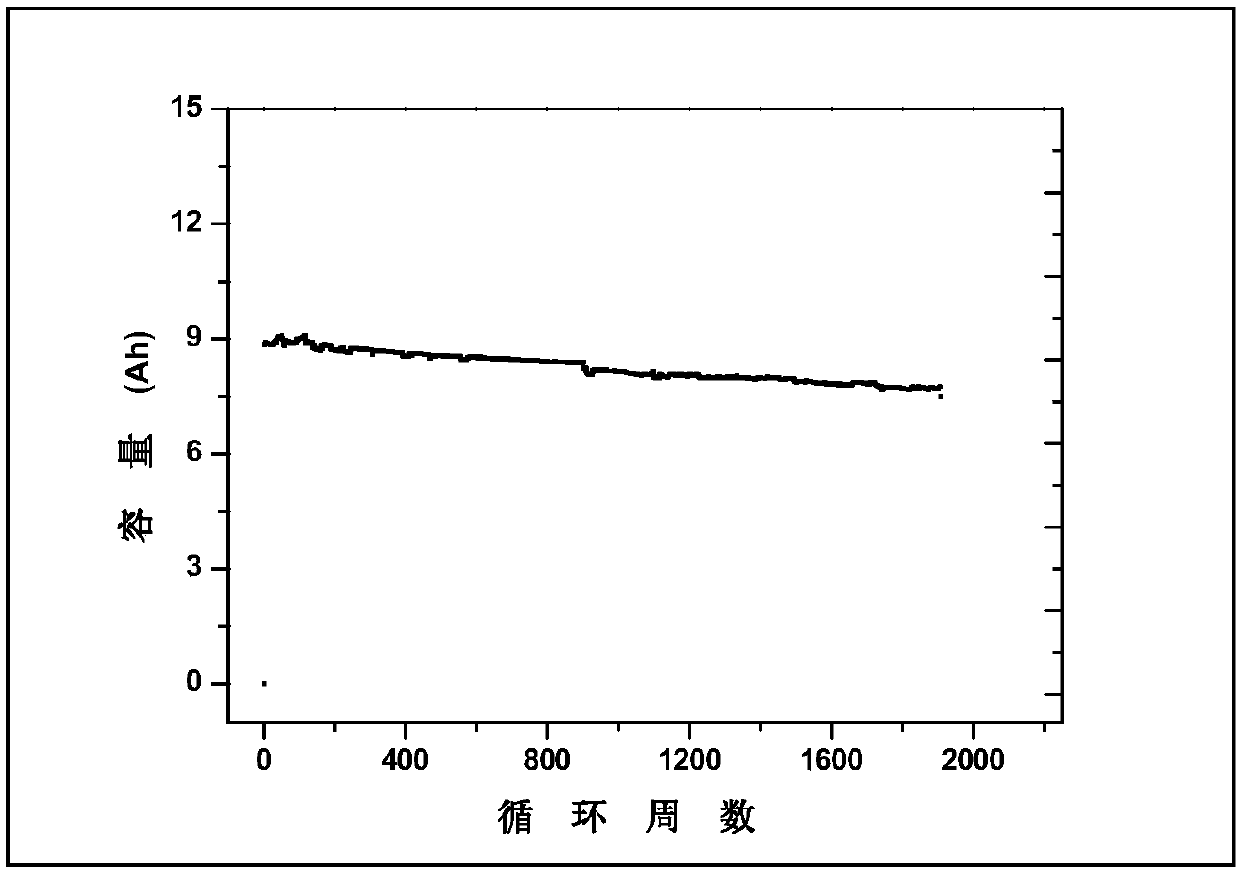

[0093] With embodiment 1, difference is that 10g dichloroethane, 83g meta-aramid slurry (wherein meta-aramid slurry is made of meta-aramid, solvent is DMAC and auxiliary solvent is CaCl 2 Mix and obtain, the quality of meta-aramid fiber is 25g) and 12.5g SiO 2 (particle size of 30nm) was added to the above A solution. A porous film was obtained; the air permeability of the porous film was 206s / 100mL; the porous film was treated at 150°C for 30 minutes, and its longitudinal shrinkage rate was 0.3%, and its transverse shrinkage rate was 0.3%; the battery production and performance test were the same as in Example 1; Battery test results: After 1899 cycles, the capacity retention rate is 86.5%.

Embodiment 3

[0095] 100g poly-p-phenylene terephthalamide pulp, 15.0g sodium hydroxide and 500g DMSO are mixed, react 4h at 50 ℃, form poly-p-phenylene terephthalamide nanofiber solution (fiber diameter is 400nm with a length of 2μm). Add 33.3g KH into the poly-p-phenylene terephthalamide nanofiber solution, stir at 70°C for 1 hour, and make the two completely react to obtain solution A. With 1.0g ethylene dichloride and 220g meta-aramid slurry (wherein the meta-aramid slurry is made of meta-aramid, the solvent is DMAC and the cosolvent is CaCl 2 Mix to obtain, the quality of meta-aramid fiber is 11g), join in the above-mentioned solution A, react at 70 ℃ for 2h to form coating slurry, the coating slurry is coated on PE base film (the thickness of base film is 16 μm, porosity 54%) surface film formation; Described film passes through coagulation bath, obtains described porous film; Described coagulation bath is DMAC and H 2 O, wherein the mass ratio of DMAC to water is 3:7, the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com