Additive for preventing thermal runaway and application of additive in secondary lithium metal battery

A lithium metal battery and additive technology, which is applied in secondary batteries, secondary battery repair/maintenance, lithium storage batteries, etc., can solve the problems of unresolved lithium metal negative electrode interface, achieve easy operation, improve electrical conductivity, and improve cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

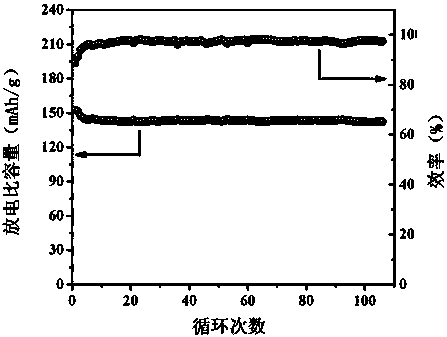

[0029] In the glove box, add additive P1 and P2 Chloroform solution (mass ratio P1:P2=1:1, 25 wt%) was coated on lithium foil, and after standing and drying, a metal lithium foil containing an additive protective layer (thickness about 10 µm) was obtained. The lithium foil containing the protective layer is used in the lithium-ion battery. Under 1 C charge and discharge, after 100 cycles of the battery, the discharge specific capacity still maintains about 140 mAh / g, and the efficiency is stable above 99%.

[0030]

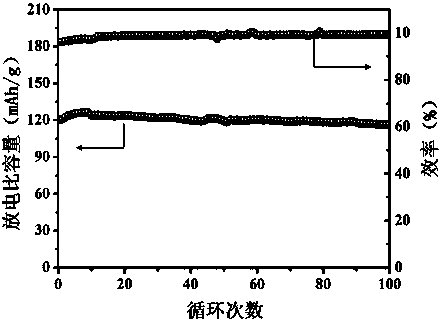

Embodiment 2

[0032] In the glove box, add additive P3 Add 1M LiTFSI to the EC-DMC solution to obtain the electrolyte. Used in lithium batteries, at 0.5 C charge and discharge, after 100 cycles of the battery, the discharge specific capacity still maintains 125mAh / g.

[0033]

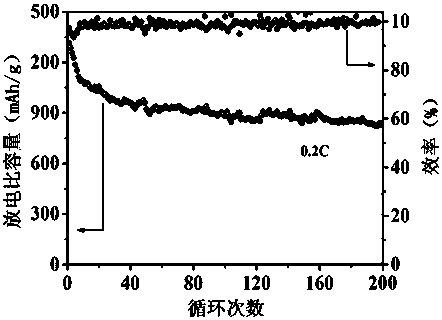

Embodiment 3

[0035] In the glove box, add additive P4 The N,N-dimethylformamide solution (50wt%) was coated on the lithium sheet and left to dry. A lithium sheet containing an additive protective layer (thickness about 20 µm) was used in a lithium-sulfur battery. After 200 cycles of charging and discharging at 0.2 C, the discharge specific capacity remained at 890 mAh / g, and the efficiency remained above 99.5%. .

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com