Solid-state lithium battery polymer electrolyte containing PEO side chain segment and preparation method thereof

An electrolyte and solid-state lithium technology, which is applied in the field of solid-state lithium battery polymer electrolyte and preparation, can solve the problems of large internal resistance of batteries, high ion conductivity, and low lithium ion conductivity, so as to improve lithium ion conductivity and improve lithium ion conductivity. Effect of ion concentration and transfer efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

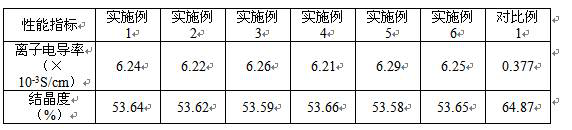

Examples

Embodiment 1

[0027] (1) Add dimercaptobutane, acrylate and polyoxyethylene chloride-terminated macromonomers with a molecular weight of 1000 to toluene, then raise the temperature, keep warm in a water bath and stir evenly to obtain a mixed material; dimercaptobutyl The alkane is 1,4-dimercaptobutane; the acrylate is methyl acrylate; the temperature of the water bath is 67°C, the speed of constant stirring is 170r / min, and the time is 36min;

[0028] (2) First add azobisisobutyronitrile to the mixed material obtained in step (1), then keep the water bath at a constant temperature and increase the speed of stirring for 2.5 minutes, then stop adding azobisisobutyronitrile, and continue stirring for 1 hour to obtain PMMA -g-PEO material; the lifting speed is 270r / min;

[0029] (3) First add N,N-diethylethylamine to the PMMA-g-PEO material obtained in step (2), continue the reaction for 3.5 hours, then add lithium salt electrolyte, mix and stir for 1 hour, and then use a centrifuge for solidif...

Embodiment 2

[0033] (1) Add dimercaptobutane, acrylate and polyoxyethylene chloride-terminated macromonomers with a molecular weight of 1000 to toluene, then raise the temperature, keep warm in a water bath and stir evenly to obtain a mixed material; dimercaptobutyl The alkane is 2,2-dimercaptobutane; the acrylate is ethyl acrylate; the temperature of the water bath is 66°C, the speed of constant stirring is 160r / min, and the time is 38min;

[0034] (2) First add azobisisobutyronitrile to the mixture obtained in step (1), then keep the water bath at a constant temperature and increase the speed of stirring for 2 minutes, then stop adding azobisisobutyronitrile, continue stirring for 1.5 hours to obtain PMMA -g-PEO material; the lifting speed is 260r / min;

[0035] (3) First add N,N-diethylethylamine to the PMMA-g-PEO material obtained in step (2), continue the reaction for 3 hours, then add lithium salt electrolyte, mix and stir for 1.5 hours, and then use a centrifuge for solidification T...

Embodiment 3

[0039] (1) Add dimercaptobutane, acrylate and polyoxyethylene chloride-terminated macromonomers with a molecular weight of 1000 to toluene, then raise the temperature, keep warm in a water bath and stir evenly to obtain a mixed material; dimercaptobutyl The alkane is 2,3-dimercaptobutane; the acrylate is 2-methyl methacrylate; the temperature of the water bath is 69°C, the speed of constant stirring is 190r / min, and the time is 32min;

[0040] (2) First add azobisisobutyronitrile to the mixture obtained in step (1), then keep the water bath at a constant temperature and increase the speed of stirring for 3 minutes, then stop adding azobisisobutyronitrile, continue stirring for 1 hour, and obtain PMMA- g-PEO material; the lifting speed is 290r / min;

[0041] (3) First add N,N-diethylethylamine to the PMMA-g-PEO material obtained in step (2), continue the reaction for 4 hours, then add lithium salt electrolyte, mix and stir for 1 hour, and then use a centrifuge for solid-liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com