Polymer solid electrolyte membrane as well as preparation method and application thereof

A solid electrolyte membrane and polymer technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of low conductivity of solid electrolyte materials, low lithium ion conductivity, poor high-voltage stability, etc., and achieve excellent high-voltage stability And the effect of cycle stability, high lithium ion conductivity, and small changes in production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a polymer solid electrolyte membrane, which is prepared by the following method:

[0055] (1) At room temperature, the monomers PES, VC, PEGMEMA, and TMPTA were mixed in a mass ratio of 1:2:0.1:0.1 to form a dilute solution, and then 2% of the total mass of the dilute solution was added AIBN and 15% of LiTFSI and 3% SN, keep stirring to form a homogeneous precursor solution;

[0056] (2) Place the non-woven fabric base film flat on the surface of the polytetrafluoroethylene flat plate and fix it, apply the precursor solution obtained in step (1) evenly on the non-woven fabric, and then cover another polytetrafluoroethylene plate on the The surface was fixed, and the whole was sealed in an aluminum-plastic film bag, placed in a 60°C oven for 24 hours, then taken out, the tetrafluoroethylene plate was removed, and kept in a 60°C vacuum oven for 24 hours to obtain the polymer solid electrolyte membrane.

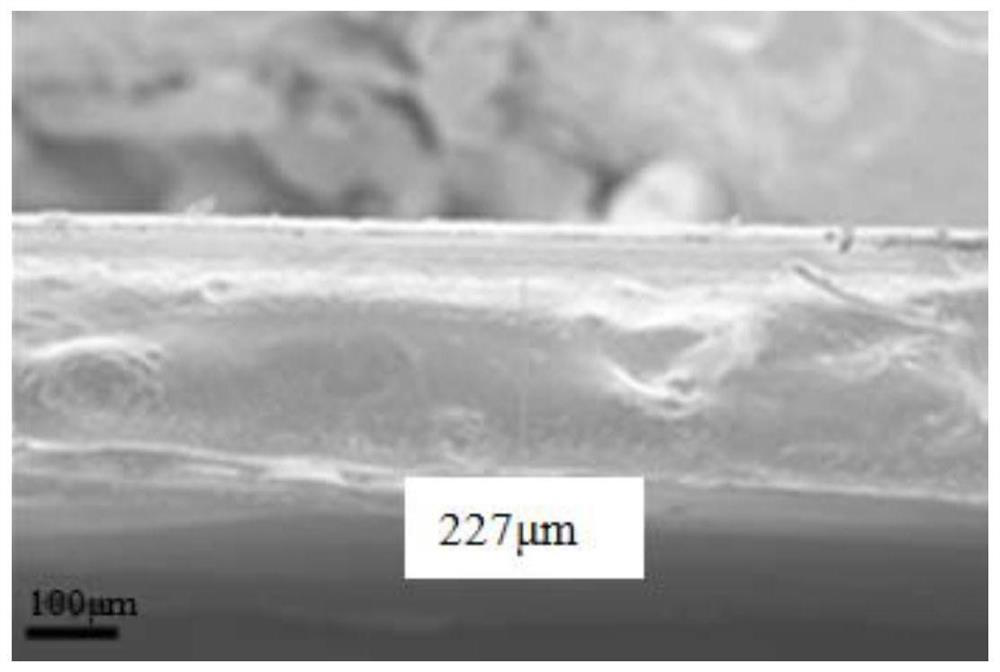

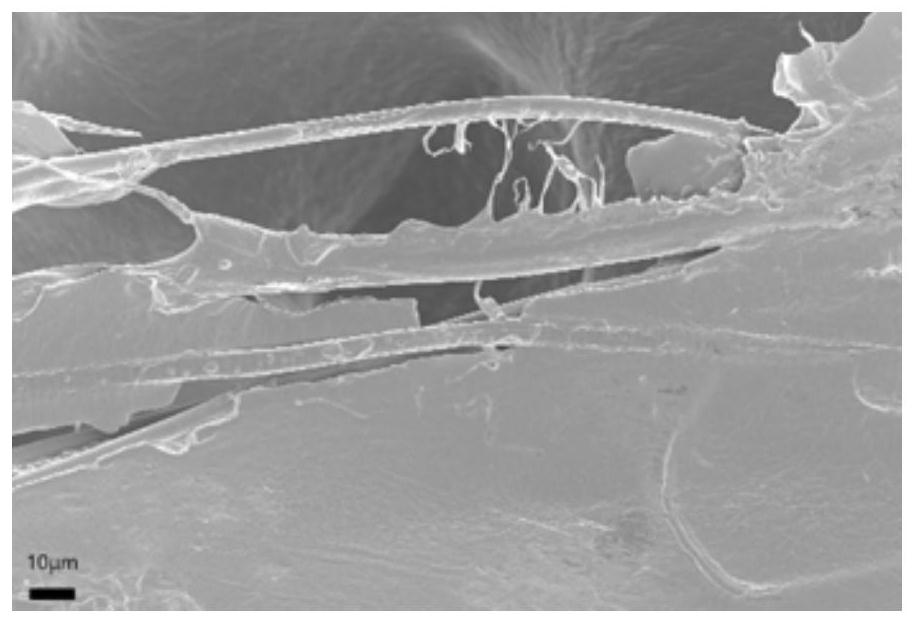

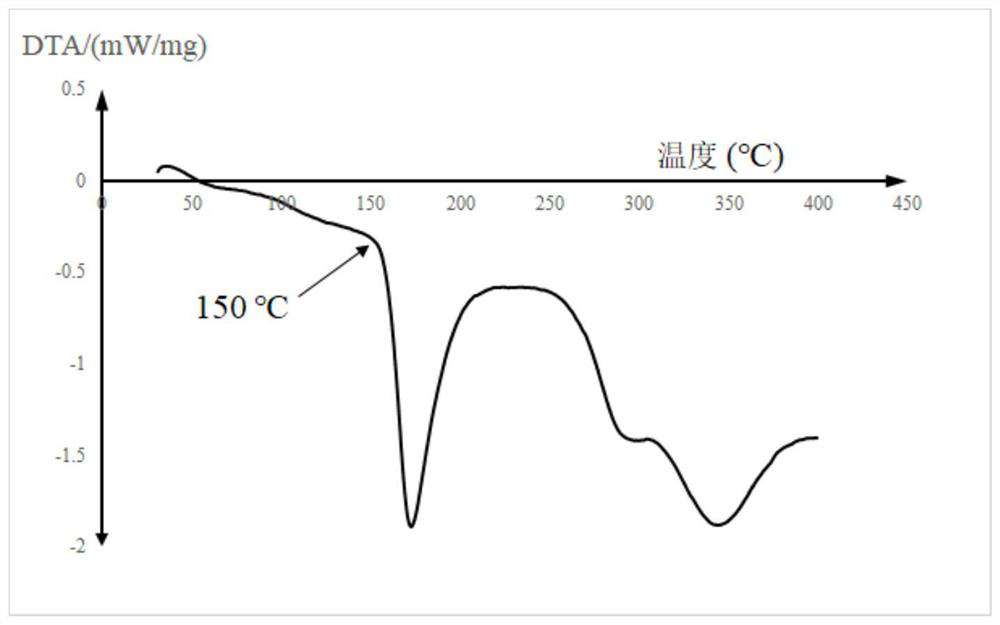

[0057] The cross-sectional view of the pol...

Embodiment 2

[0062] This embodiment provides a polymer solid electrolyte membrane, which is prepared by the following method:

[0063] (1) At room temperature, mix the monomers PES, VC, PEGMEMA, and TMPTA at a mass ratio of 1:0.25:0.06:0.06 to form a dilute solution, and then add 2% AIBN and 15% LiTFSI to the total mass of the dilute solution in sequence and 3% SN, keep stirring to form a homogeneous precursor solution;

[0064] (2) Place the non-woven fabric base film flat on the surface of the polytetrafluoroethylene flat plate and fix it, apply the precursor solution obtained in step (1) evenly on the non-woven fabric, and then cover another polytetrafluoroethylene plate on the The surface was fixed, and the whole was sealed in an aluminum-plastic film bag, placed in a 60°C oven for 24 hours, then taken out, the tetrafluoroethylene plate was removed, and kept in a 60°C vacuum oven for 24 hours to obtain the polymer solid electrolyte membrane.

Embodiment 3

[0066] The only difference between this embodiment and Embodiment 1 is that PES:VC=1:4, and other conditions and parameters are completely the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com