Lithium battery diaphragm and preparation method thereof

A lithium battery diaphragm and polycondensate technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of poor compatibility of the base film, affecting lithium ion transmission, and further improvement of weather resistance, achieving excellent Thermal stability, low device dependence, good wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

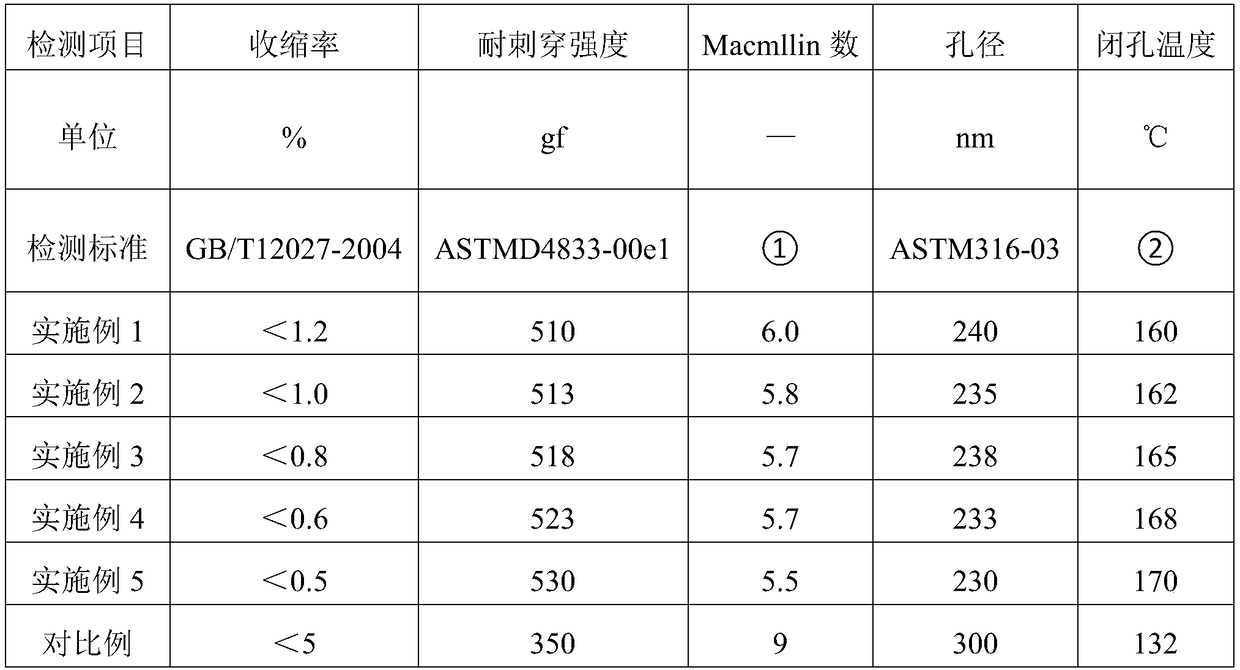

Examples

Embodiment 1

[0036] A preparation method of a lithium battery diaphragm, comprising the steps of:

[0037] ⅠHydroxyl protection: Dissolve 2.51kg of dihydro-2,4,6-trioxo-1,3,5-triazine-1,3(2H,4H)-dipropionic acid in N,N-dimethyl A solution was formed in 10 kg of formamide, stirred in an ice-water bath for 10 minutes, then 0.3 kg of imidazole and 1 kg of trimethylchlorosilane were added thereto, and the stirring was continued for 2 hours, after which the reaction mixture was diluted with ethyl acetate and washed 3 times with water. Then washed with saturated brine for 3 times, finally dehydrated with anhydrous magnesium sulfate, filtered, and rotary evaporated to remove the solvent to obtain an intermediate product;

[0038] Preparation of polycondensate II: 1 kg of the intermediate product prepared through step I, 1.36 kg of 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane, 0.4 kg of 1-hydroxybenzotriazole kg, 0.3kg of 4-dimethylaminopyridine was dissolved in 10kg of dimethyl sulfoxide t...

Embodiment 2

[0047] A preparation method of a lithium battery diaphragm, comprising the steps of:

[0048] ⅠHydroxyl protection: Dissolve 2.51kg of dihydro-2,4,6-trioxo-1,3,5-triazine-1,3(2H,4H)-dipropionic acid in N,N-dimethyl A solution was formed in 12 kg of formamide, stirred in an ice-water bath for 13 minutes, then 0.35 kg of imidazole and 1 kg of trimethylchlorosilane were added thereto, and the stirring was continued for 2.3 hours. After that, the reaction mixture was diluted with ethyl acetate and washed 4 times with water. Then washed with saturated brine for 4 times, finally dehydrated with anhydrous magnesium sulfate, filtered, and rotary evaporated to remove the solvent to obtain an intermediate product;

[0049] Preparation of polycondensate II: 1 kg of the intermediate product prepared through step I, 1.36 kg of 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane, 0.45 kg of 1-hydroxybenzotriazole kg, 0.3kg of 4-dimethylaminopyridine was dissolved in 12kg of N,N-dimethylform...

Embodiment 3

[0058] A preparation method of a lithium battery diaphragm, comprising the steps of:

[0059] ⅠHydroxyl protection: Dissolve 2.51kg of dihydro-2,4,6-trioxo-1,3,5-triazine-1,3(2H,4H)-dipropionic acid in N,N-dimethyl A solution was formed in 13 kg of formamide, stirred in an ice-water bath for 15 minutes, then 0.4 kg of imidazole and 1 kg of trimethylchlorosilane were added thereto, and the stirring was continued for 2.5 hours. After that, the reaction mixture was diluted with ethyl acetate and washed 4 times with water. Then washed with saturated brine for 4 times, finally dehydrated with anhydrous magnesium sulfate, filtered, and rotary evaporated to remove the solvent to obtain an intermediate product;

[0060] Preparation of polycondensate II: 1 kg of the intermediate product prepared through step I, 1.36 kg of 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane, 0.5 kg of 1-hydroxybenzotriazole kg, 0.3kg of 4-dimethylaminopyridine was dissolved in 13kg of N-methylpyrrolidon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com