Composite cathode material for lithium ion batteries and preparation method thereof

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc. The effect of lithium ion conduction rate, increasing specific capacity, and reducing impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

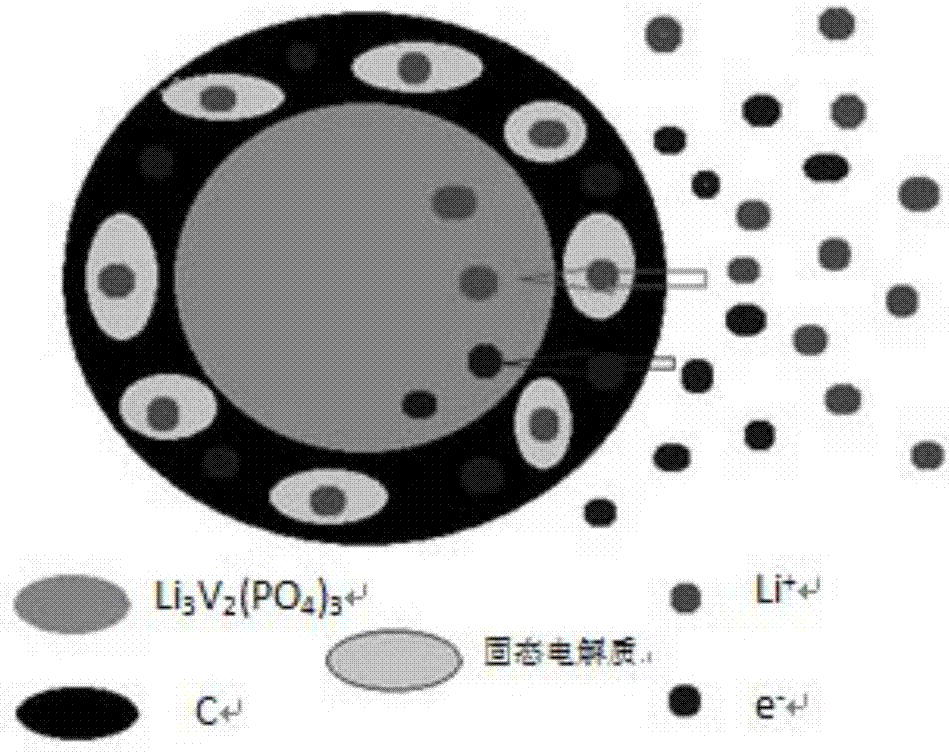

[0016] With ascorbic acid as carbon source, Li 7 La 3 Zr 2 o 12 is a solid electrolyte, and Li 3 V 2 (PO 4 ) 3 Co-preparation of double-coated composite cathode materials.

[0017] Step 1. Dissolve ascorbic acid in deionized water, stir at 80°C, and then add LiNO 3 ·H 2 O, La(NO 3 ) 3 ·6H 2 O and Zr(NO 3 ) 4 · 5 h 2 O, molar ratio ascorbic acid:LiNO 3 ·H 2 O: La(NO 3 ) 3 ·6H 2 O: Zr(NO 3 ) 4 · 5 h 2 O=3.5:7:3:12, continue to stir until a sol is formed.

[0018] Step 2, add Li prepared earlier 3 V 2 (PO 4 ) 3 Materials, transferred to a high-pressure reactor, reacted at 180-200 °C for 24-40 hours, and then stirred the obtained product at 70-90 °C until the water was evaporated,

[0019] Step 3. Finally, the obtained precursor is sintered at 700-780° C. for 8-10 hours under an inert gas atmosphere to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com