Silicon-carbon system lithium ion battery electrolyte and silicon-carbon system lithium ion battery

A lithium-ion battery and electrolyte technology, which is applied in the field of silicon-carbon system lithium-ion battery electrolyte and silicon-carbon system lithium-ion battery, can solve the problems of high-temperature cycle performance to be improved, and achieve high residual capacity and recoverable capacity. Cycle performance, effect of reducing expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

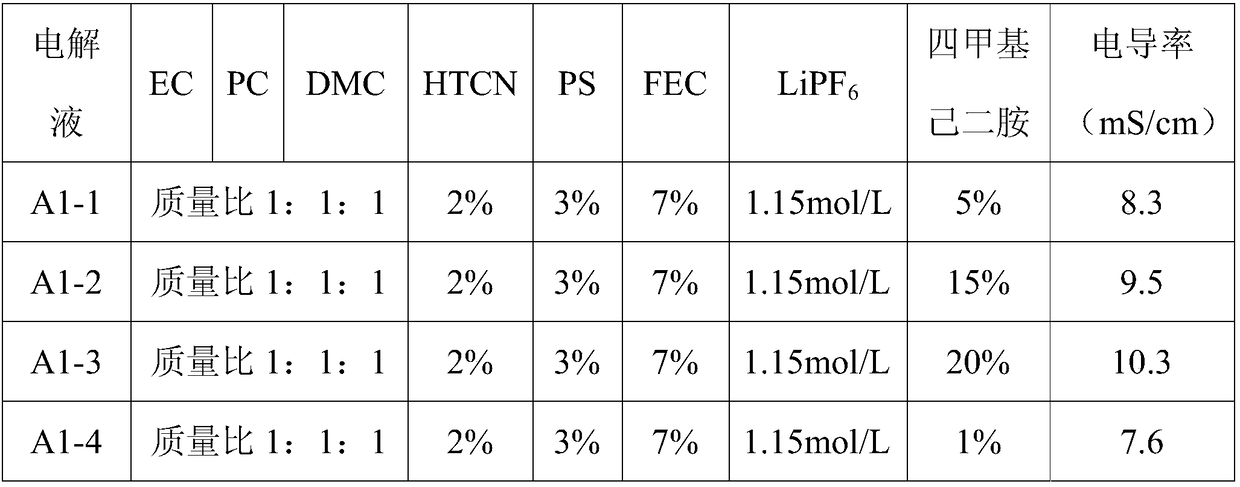

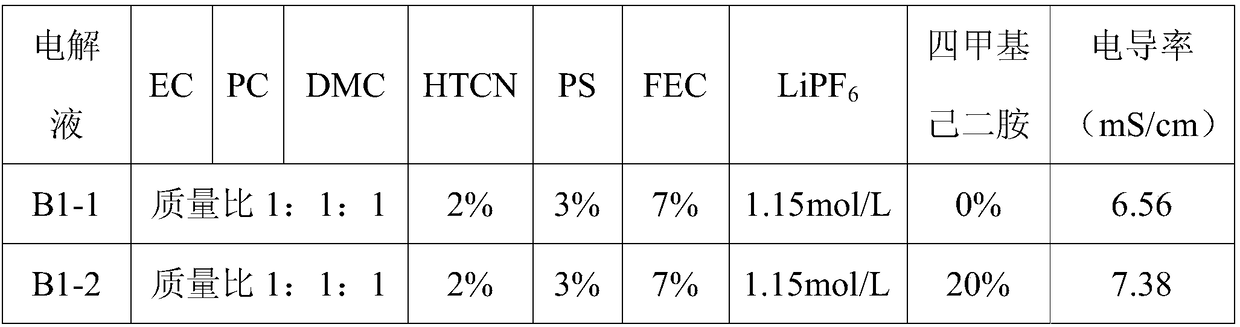

[0045] In this example, the preparation of lithium-ion battery electrolyte solutions A1-1 to A1-4 is provided. The preparation steps of the electrolyte solution are: mix dimethyl carbonate, ethylene carbonate and propylene carbonate at a ratio of 1:1:1 The mass ratio is mixed as an organic solvent; add additives to the organic solvent, after mixing evenly, add LiPF 6 , to obtain a mixed solution, which is the electrolyte. The relationship between the number of the obtained electrolyte and the composition of the electrolyte additives and the results of the conductivity of the electrolyte are shown in Table 1-1:

[0046] Table 1-1

[0047]

Embodiment 2

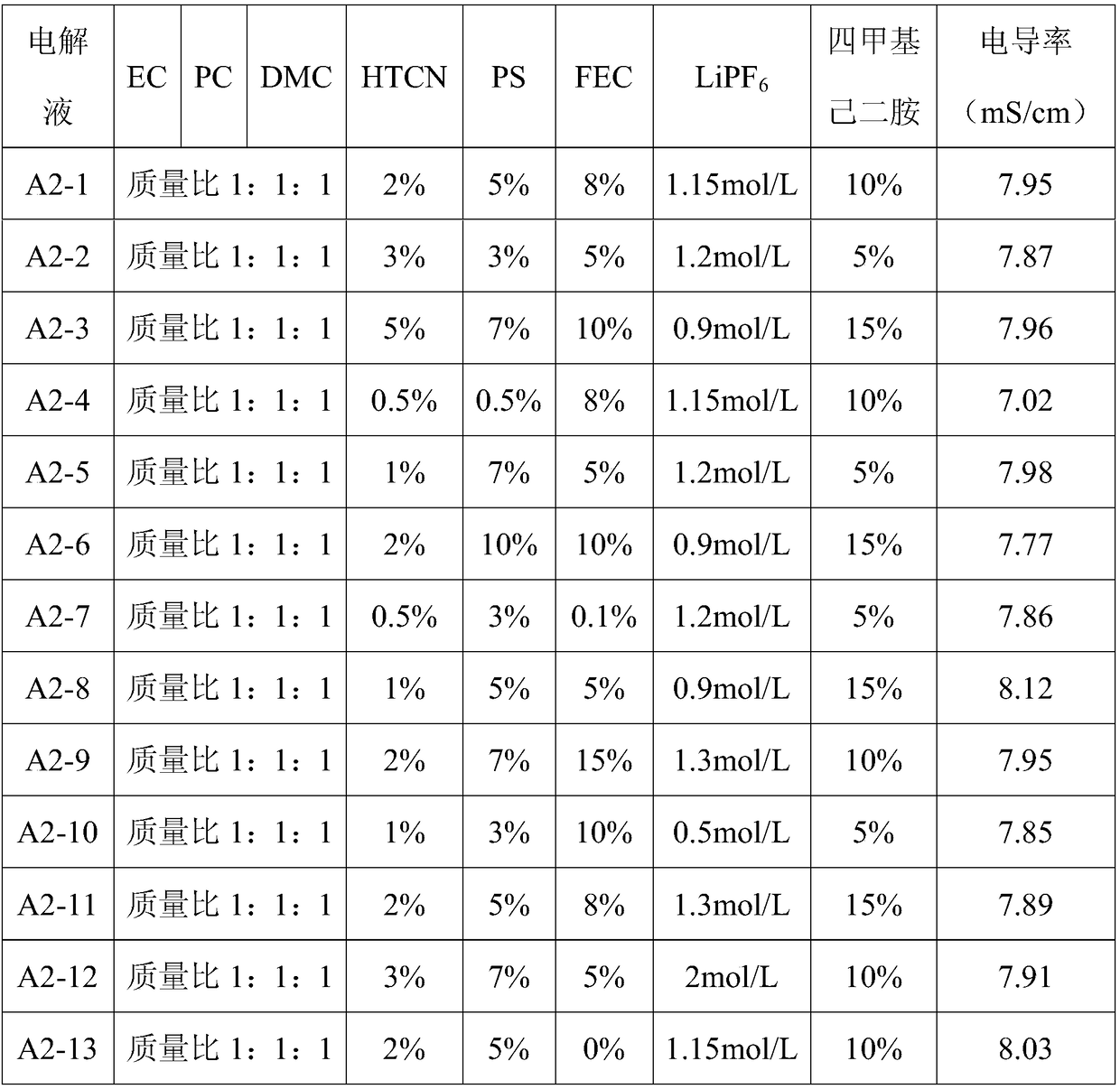

[0053] In this example, the preparation of lithium-ion battery electrolyte solutions A2-1 to A2-12 is provided. The preparation steps of the electrolyte solution are: mix dimethyl carbonate, ethylene carbonate and propylene carbonate at a ratio of 1:1:1 The mass ratio is mixed as an organic solvent; add additives to the organic solvent, after mixing evenly, add LiPF 6 , to obtain a mixed solution, which is the electrolyte. The relationship between the number of the obtained electrolyte and the composition of the electrolyte additives and the results of the conductivity of the electrolyte are shown in Table 2-1:

[0054] table 2-1

[0055]

Embodiment 3

[0061] The electrolyte solution prepared in Example 1-2 and Comparative Example 1-2 was used to prepare a lithium ion battery, and the lithium ion battery included a positive electrode sheet, a negative electrode sheet, a separator and an electrolyte solution.

[0062] Production of the positive electrode sheet:

[0063] The positive electrode active material lithium cobaltate (LiCoO 2 ), the conductive agent acetylene black, and the binder polyvinylidene fluoride (PVDF) are fully stirred and mixed in N-methylpyrrolidone (NMP) solvent at a weight ratio of 96:2:2 to form a uniform positive electrode slurry; The slurry was coated on the positive electrode current collector AA foil, dried and cold pressed to obtain the positive electrode sheet.

[0064] Production of negative electrode sheet:

[0065] Negative electrode active material silicon carbon, conductive agent acetylene black, binder styrene-hexyl rubber (SBR), thickener sodium carboxymethyl cellulose (CMC) in an approp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com