Polymer electrolyte of lithium ion battery and preparation method thereof

A lithium-ion battery, lithium polymer technology, applied in the manufacture of electrolyte batteries, solid electrolytes, non-aqueous electrolytes, etc., can solve the problems of poor stability of gel polymer electrolytes, poor compatibility of electrode materials, and narrow electrochemical windows, etc. Achieve the effect of excellent lithium ion conductivity, simple production process, and high ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

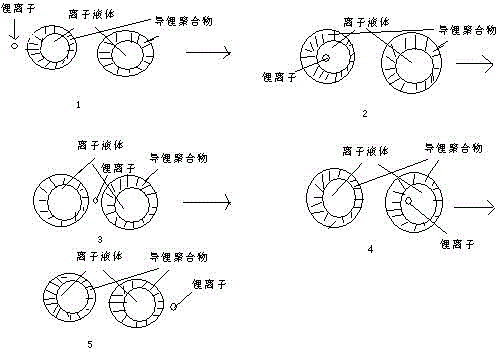

[0036]1) 25 parts by weight of polypropylene oxide are dissolved in toluene to form a solution, then 45 parts by weight of 1-ethyl-2-methylpyrazole tetrafluoroborate and 2 parts by weight of alkylphenol Add oxyethylene ether formaldehyde into the solution, and slowly stir and emulsify at a speed of 40r / min for 20min, so that 1-ethyl-2-methylpyrazole tetrafluoroborate forms tiny droplets in the solution and disperses evenly In solution;

[0037] 2) Add the solution obtained in step 1) into the polymerization kettle to carry out self-polymerization and self-crosslinking reactions to form 1-ethyl-2-methylpyrazole tetrafluoroborate as the core and polypropylene oxide as the core The tiny particles with microcapsule structure in the shell layer are discharged and dried;

[0038] 3) Evenly disperse the tiny particles with a microcapsule structure obtained in step 2) into dimethylformamide, then add 5 parts by weight of lithium tetrafluoroborate and 6 parts by weight of polyvinyl ch...

Embodiment 2

[0041] 1) 35 parts by weight of polyethylene succinate are dissolved in acetone to form a solution, and then 35 parts by weight of 1-methyl-3-ethyl imidazolium dicyanoimine and 5 parts by weight of arane Add phenol polyoxyethylene ether formaldehyde into the solution, and slowly stir and emulsify for 30 minutes at a speed of 80r / min, so that 1-methyl-3-ethylimidazolium dicyanoimine forms tiny droplets in the solution, uniform dispersed in the solution;

[0042] 2) Add the solution obtained in step 1) into the polymerization kettle to carry out self-polymerization and self-crosslinking reactions to form polyethylene succinate with 1-methyl-3-ethylimidazolium dicyanoimine as the core The ester is a shell of tiny particles with a microcapsule structure, which is discharged and dried;

[0043] 3) Evenly disperse the tiny particles with a microcapsule structure obtained in step 2) into dimethyl acetylene, then add 5 parts by weight of lithium bisoxalate borate and 12 parts by weig...

Embodiment 3

[0046] 1) Dissolve 30 parts by weight of polyvinylidene fluoride in acetonitrile to form a solution, then mix 35 parts by weight of N-methyl-N-propylpyrrole trifluoromethanesulfonamide and 3 parts by weight of polyoxyethylene polyoxyethylene Add the propylene block copolymer into the solution, and slowly stir and emulsify at a speed of 50r / min for 30min, so that N-methyl-N-propylpyrrole trifluoromethanesulfonamide forms tiny droplets in the solution and disperses evenly In solution;

[0047] 2) Add the solution obtained in step 1) into the polymerization kettle for self-polymerization and self-crosslinking reactions to form N-methyl-N-propylpyrrole trifluoromethanesulfonamide as the core and polyvinylidene fluoride as the shell Tiny particles with microcapsule structure in the layer are discharged and dried;

[0048] 3) Evenly disperse the tiny particles with a microcapsule structure obtained in step 2) into N-methylpyrrolidone, then add 6 parts by weight of lithium trifluoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com