Cold-resistant flame retardant thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and cold-resistant plasticizer technology, applied in the field of thermoplastic elastomers, can solve the problems of low temperature below -40 ℃, poor low temperature resistance, poor elasticity, etc., to achieve high production efficiency, excellent flame retardant performance, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

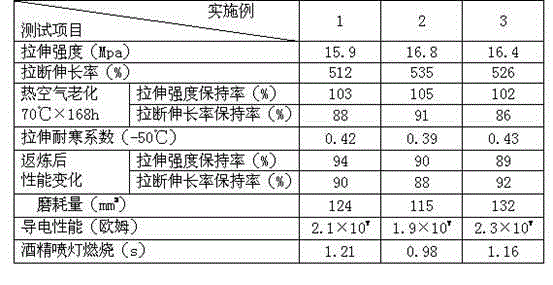

Examples

Embodiment 1

[0027] This embodiment provides a cold-resistant flame-retardant thermoplastic elastomer, which is made of the following raw materials in parts by weight:

[0028] 30 parts of PBR, 30 parts of PVC, 40 parts of CPE, 10 parts of PNBR-18, 5 parts of zinc oxide, 2 parts of stearic acid, 2 parts of paraffin oil, 1 part of sulfur, 2 parts of DCP, 3 parts of TAIC, Accelerator M 0.5 1 part of accelerator DM, 1 part of anti-aging agent A, 1 part of anti-aging agent D, 1 part of tribasic lead sulfate, 1 part of dibasic lead phosphite, 6 parts of antistatic agent P, 10 parts of conductive carbon black, 15 parts of white carbon black, 10 parts of DOP, 10 parts of chlorinated paraffin, 10 parts of TCP, 10 parts of activated aluminum hydroxide, 5 parts of red phosphorus, and 5 parts of antimony trioxide.

[0029] The PVC selected is SG-3 type PVC resin with a degree of polymerization of 1250-1350; the chlorine content of CPE is 16%-24%.

[0030] The preparation method of the present embodi...

Embodiment 2

[0038] This embodiment provides a cold-resistant flame-retardant thermoplastic elastomer, which is made of the following raw materials in parts by weight:

[0039] 40 parts of PBR, 40 parts of PVC, 20 parts of CPE, 10 parts of PNBR-18, 5 parts of zinc oxide, 2 parts of stearic acid, 2 parts of paraffin oil, 1.2 parts of sulfur, 1 part of DCP, 3 parts of TAIC, accelerator CZ 1 0.5 parts of accelerator TMTD, 1 part of anti-aging agent 2246-S, 1 part of anti-aging agent RD, 1 part of tribasic lead sulfate, 1 part of dibasic lead phosphite, 6 parts of antistatic agent TM, 12 parts of conductive carbon black 12 parts of white carbon black, 15 parts of DOA, 20 parts of TCEP, 10 parts of magnesium hydroxide, 10 parts of zinc borate, and 10 parts of ammonium polyphosphate.

[0040] The PVC selected is SG-3 type PVC resin with a degree of polymerization of 1250-1350; the chlorine content of CPE is 16%-24%.

[0041] The preparation method of this embodiment is the same as that of Examp...

Embodiment 3

[0043] This embodiment provides a cold-resistant flame-retardant thermoplastic elastomer, which is made of the following raw materials in parts by weight:

[0044] 50 parts of PBR, 20 parts of PVC, 30 parts of CPE, 10 parts of PNBR-18, 5 parts of zinc oxide, 2 parts of stearic acid, 2 parts of paraffin oil, 1.5 parts of sulfur, 1.5 parts of DCP, 3 parts of TAIC, accelerator CED 1 1 part, accelerator TMTD 1 part, anti-aging agent 2246-S 1 part, anti-aging agent 4010NA 1 part, tribasic lead sulfate 1 part, dibasic lead phosphite 1 part, antistatic agent SA 8 parts, conductive carbon black 15 parts 10 parts of white carbon black, 20 parts of DOS, 10 parts of TDCPP, 5 parts of CDP, 10 parts of antimony trioxide, 10 parts of ammonium polyphosphate, 10 parts of melamine cyanurate, and 10 parts of decabromodiphenyl ether.

[0045] The PVC selected is SG-3 type PVC resin with a degree of polymerization of 1250-1350; the chlorine content of CPE is 16%-24%.

[0046]The preparation meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com