Carbon fiber/NiCo2O4/graphene composite material preparation method

A composite material and carbon fiber technology, applied in the field of nanomaterials, can solve the problems of electrochemical performance restriction, theoretical capacity gap, poor electrical conductivity, etc., and achieve the effect of improving electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

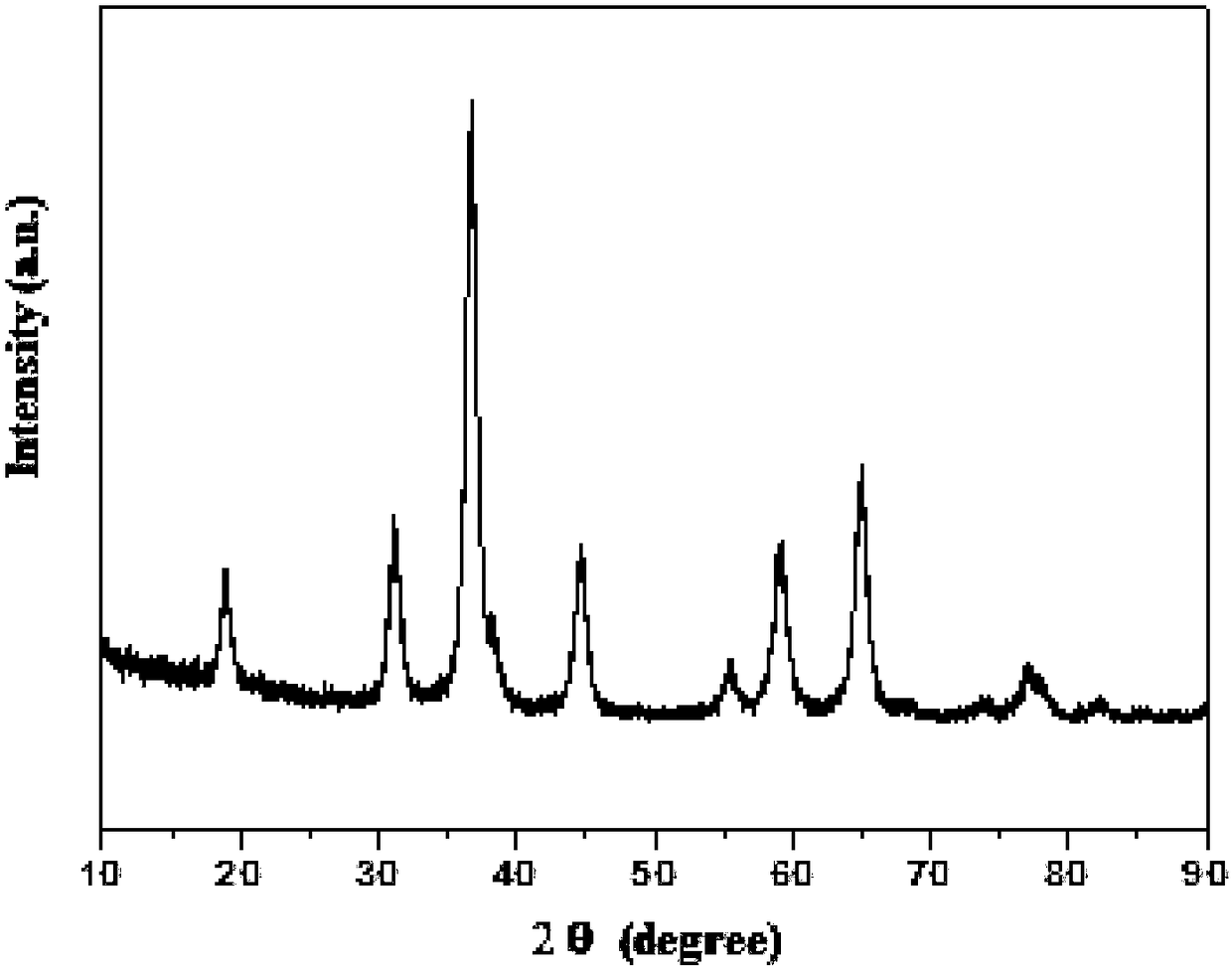

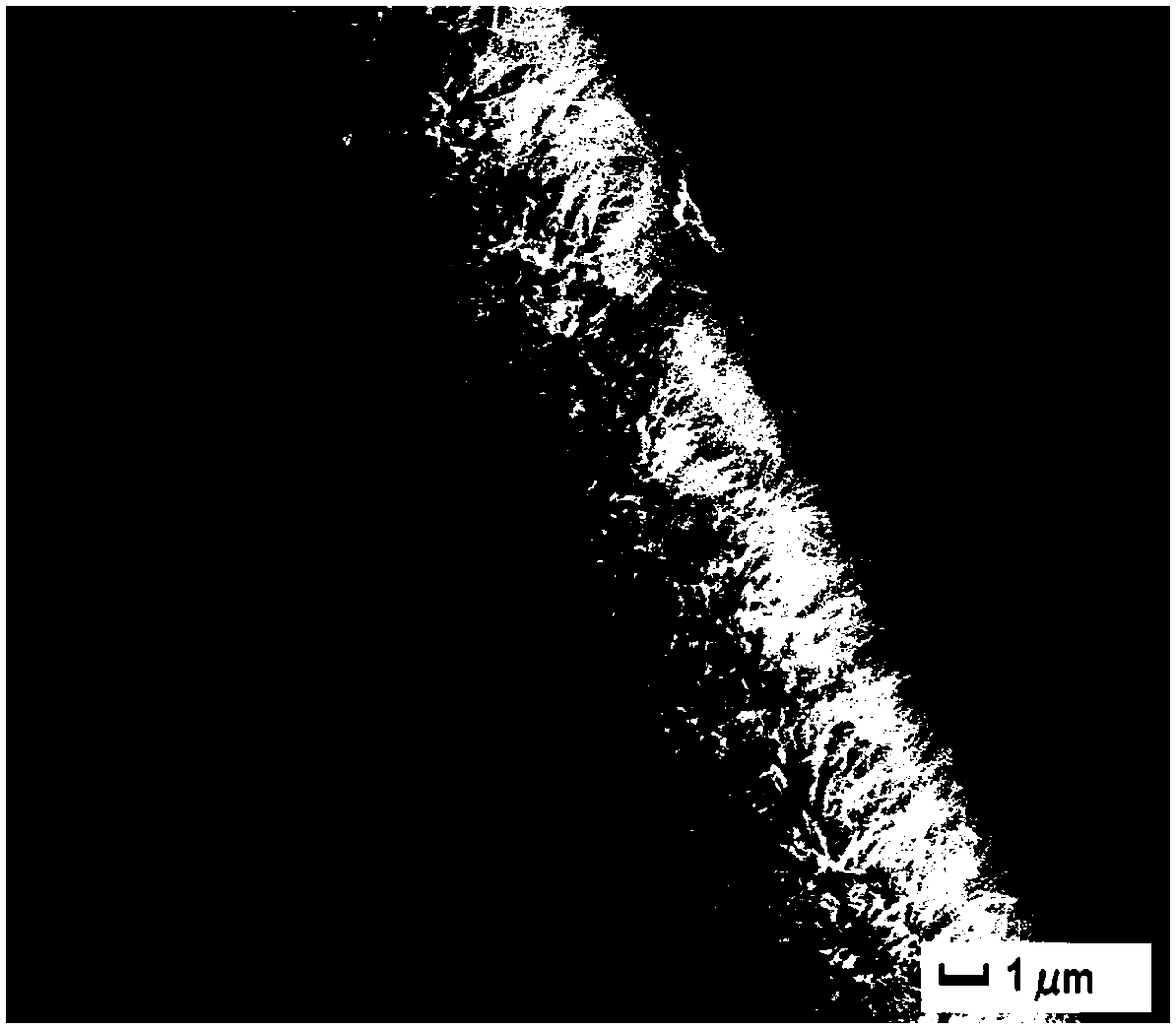

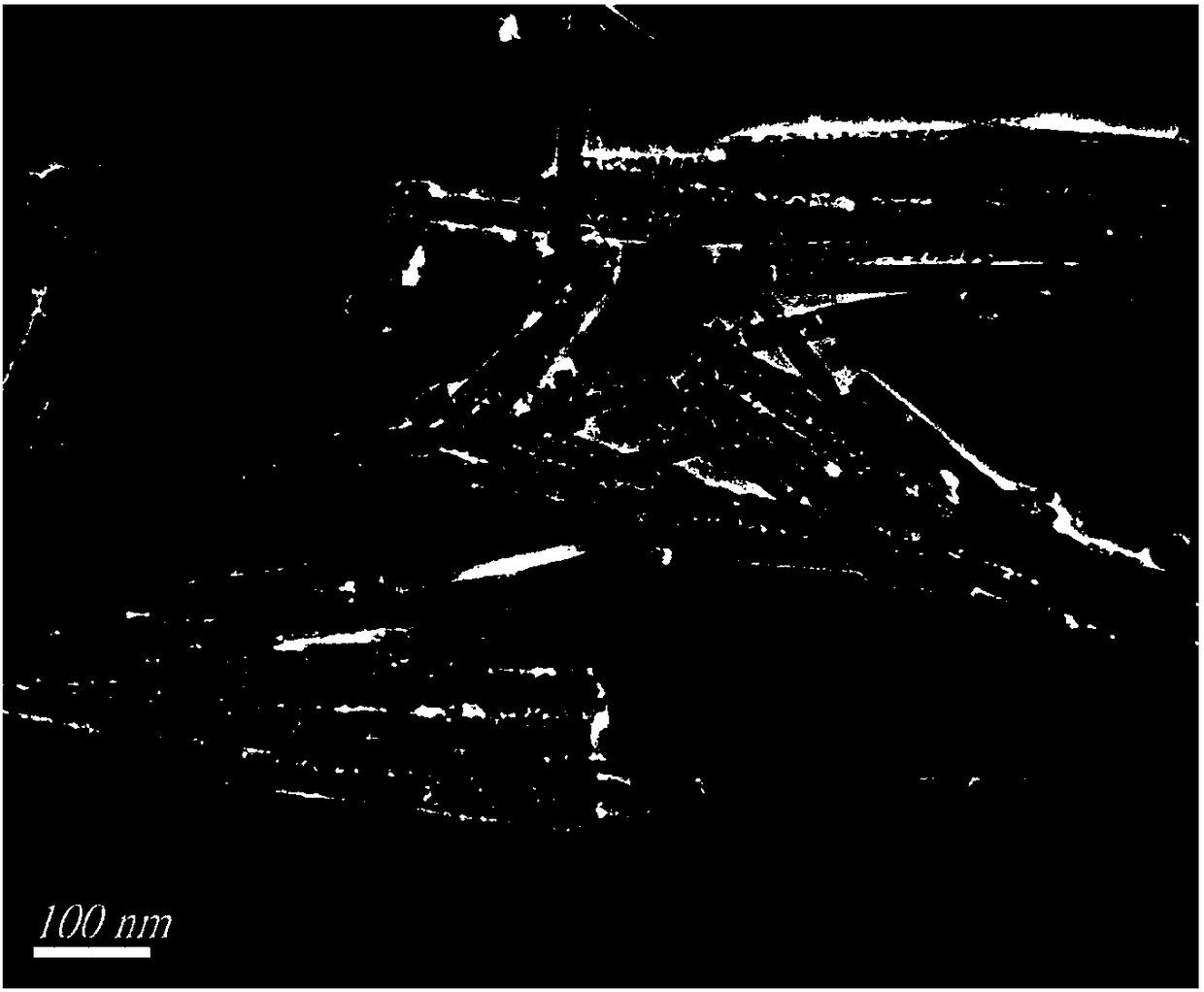

Embodiment 1

[0025] 0.001mol Co(NO 3 ) 2 ·6H 2 O, 0.0005mol Ni(NO 3 ) 2 ·6H 2 O and 0.01mol urea were dissolved in a mixed solution of 25ml of distilled water and 25ml of ethanol, dispersed evenly by ultrasonic, the mixture was transferred to a reaction kettle, added carbon fiber, and reacted at 130°C for 8h, the resulting product was cleaned with distilled water and dried to obtain surface-supported nickel Carbon fiber of cobalt precursor; add 0.002mol urea to 50ml of 0.2mg / ml porous graphene oxide aqueous solution, ultrasonically treat for 6h, transfer the mixture into a reaction kettle, add carbon fiber loaded with nickel-cobalt precursor, and heat at 180°C React for 6h, then dry at 60°C for 12h; finally, heat-treat the resulting product in a tube furnace at 300°C for 3h to obtain carbon fiber / NiCo 2 o 4 / graphene composites. The carbon fiber / NiCo prepared in this embodiment 2 o 4 / Graphene composite materials are used in supercapacitor electrodes to test their electrochemical...

Embodiment 2

[0027] 0.003mol CoCl 2 ·6H 2 O, 0.0015mol NiCl 2 ·6H 2O and 0.02mol urea were dissolved in a mixed solution of 25ml distilled water and 25ml ethanol, dispersed evenly by ultrasonic, the mixture was transferred to a reaction kettle, carbon fiber was added, and reacted at 120°C for 9h, the obtained product was cleaned with distilled water and dried to obtain surface-supported nickel Carbon fiber of cobalt precursor; add 0.006mol urea to 50ml of 0.5mg / ml porous graphene oxide aqueous solution, sonicate for 6h, transfer the mixture into a reaction kettle, add carbon fiber loaded with nickel-cobalt precursor, and heat at 120°C Reaction for 10 h, followed by drying at 60 °C for 12 h; finally, heat treatment of the obtained product in a tube furnace at 400 °C for 1 h to obtain carbon fiber / NiCo 2 o 4 / graphene composites. The carbon fiber / NiCo prepared in this embodiment 2 o 4 / Graphene composites are used in supercapacitor electrodes to test their electrochemical performance...

Embodiment 3

[0029] 0.004mol Co(NO 3 ) 2 ·6H 2 O, 0.002mol Ni(NO 3 ) 2 ·6H 2 O and 0.024mol urea were dissolved in a mixed solution of 25ml distilled water and 25ml ethanol, dispersed evenly by ultrasonic, the mixture was transferred to a reaction kettle, carbon fiber was added, and reacted at 100°C for 10h. The obtained product was cleaned with distilled water and dried to obtain surface loading Carbon fibers of nickel-cobalt precursors; add 0.003mol urea to 50ml of 0.4mg / ml porous graphene oxide aqueous solution, ultrasonically treat for 6h, transfer the mixture into a reactor, add carbon fibers loaded with nickel-cobalt precursors, and heat at 150°C The reaction was carried out at 60°C for 8h, and then dried at 60°C for 12h; finally, the product was heat-treated in a tube furnace at 300°C for 2h to obtain carbon fiber / NiCo 2 o 4 / graphene composites. The carbon fiber / NiCo prepared in this embodiment 2 o 4 / Graphene composite materials are used in supercapacitor electrodes to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com