High-dispersion antiferroelectric submicron ceramic powder and preparation method thereof

A ceramic powder and antiferroelectric technology, which is applied in the field of highly dispersed antiferroelectric submicron ceramic powder and its preparation, can solve problems such as hard agglomeration, inability to fully utilize the advantages of high energy storage, and deterioration of ceramic electrical resistance. Achieve the effects of high electric strength, compact microstructure, and high energy storage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the present invention can be realized by the following technical solutions:

[0025] First, ceramic powders were prepared by solid-phase synthesis. The chemical composition of the above-mentioned highly dispersed antiferroelectric ceramic powder conforms to the general chemical formula: Pb 1-1.5x La x Zr 1-y-z Ti y sn z o 3 , 0.0≤x≤0.15, 0≤y≤0.10, 0.0≤z≤0.60. Preferably, 0.04≤x≤0.14, 0≤y≤0.08, 0≤z≤0.60. The above ceramic powder can be Pb 3 o 4 , La 2 o 3 , ZrO 2 、TiO 2 , SnO 2 and other oxides as raw materials.

[0026] This solid-phase synthesis may comprise the following steps: (1) Pb with a purity higher than 99% 3 o 4 , La 2 o 3 , ZrO 2 、TiO 2 , SnO 2 as raw material, and according to Pb 1-1.5x La x Zr 1-y-z Ti y sn z o 3 stoichiometric ratio weighing. Preferably, Pb 3 o 4 An excess of 0-5% can supplement the lattice defects caused by the volatilization of Pb element during synthesis and sintering. (2) Using w...

Embodiment 1

[0042] The chemical composition of the antiferroelectric ceramic material: Pb 1-1.5x La x Zr 1-y-z Ti y sn z o 3 , x=0.06, y=0.0, z=0.55, using traditional solid-phase synthesis-two-step wet grinding to prepare antiferroelectric powder and ceramics includes the following steps:

[0043] (1) Pb with a purity higher than 99% 3 o 4 , La 2 o 3 , ZrO 2 、TiO 2 , SnO 2 as the raw material; according to the stoichiometric ratio of the above chemical formula, the materials were weighed, the materials were mixed by wet roller milling, and the zirconia balls were used as the ball milling medium, and mixed according to the weight ratio of material: ball milling medium: ethanol = 1:5:0.8 for 24 hours, at 70 Dry at ℃;

[0044] (2) Calcining the dried powder at 1000°C for 2 hours;

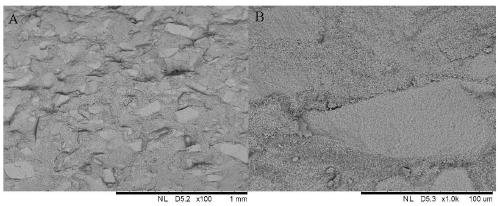

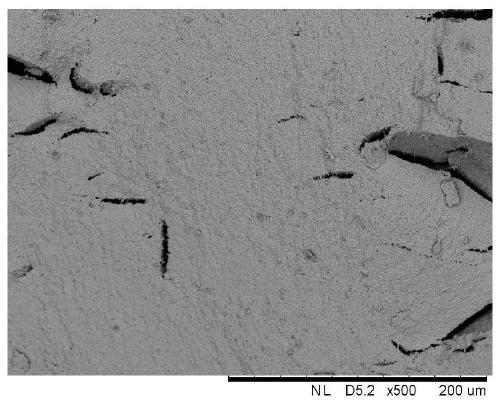

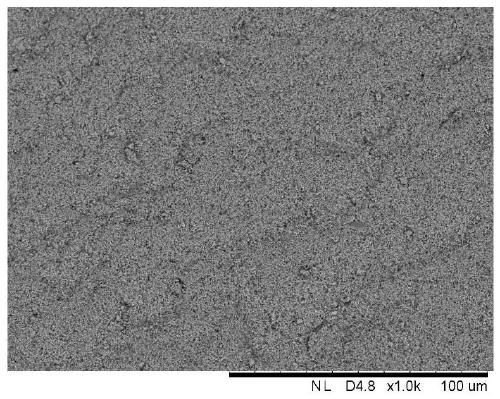

[0045] (3) Take 100-130g of the calcined powder, add 2% sintering aid according to the weight percentage, take 1.0-1.3kg with 2mm zirconia balls as grinding balls, and use agitating mill for fine gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com