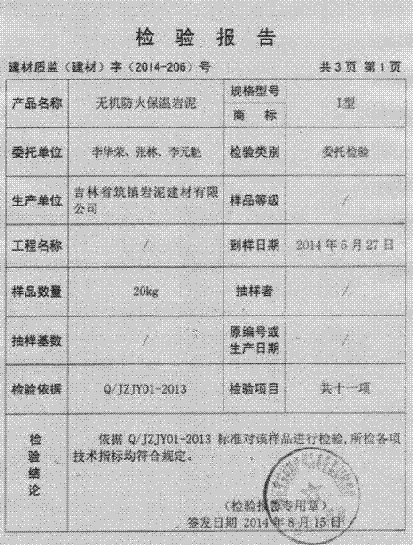

Inorganic waterproof heat insulation rock mud

A technology for fire prevention and heat preservation and rock mud, applied in the field of inorganic fireproof heat preservation rock mud, can solve the problems of defective composition and ratio rationality, high maintenance and renewal costs, burden on property owners, etc., and achieves simple and convenient construction process, light weight, Unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 An inorganic fireproof and thermal insulation rock mud, the composition materials and weight ratio are as follows:

[0026] Portland cement: 8%; bentonite: 6%; flocculent iron fiber short filament 4%; glass fiber short filament 2%; foam stone particles 10%; kerogen shale particles 20%; hydrophobic perlite particles 50%;

[0027] The particle size of flocculent short iron fiber is 2500 mesh;

[0028] The particle size of glass fiber short filament is 700 mesh;

[0029] The particle size of pumice particles is 30 mesh;

[0030] The particle size of kerogen shale is 30 mesh;

[0031] The particle size of hydrophobic perlite particles (expanded sand) is 18 mesh.

[0032] The inorganic fireproof and thermal insulation rock mud is co-produced by Jilin Province Zhuzhen Rock Mud Building Materials Co., Ltd. According to the proportion of the inorganic fireproof and thermal insulation rock mud, the raw materials can be mixed evenly. Add water and stir to form a pl...

Embodiment 2

[0040] Example 2 An inorganic fireproof and thermal insulation rock mud, the composition materials and weight ratio are as follows:

[0041] Portland cement: 6%; bentonite: 8%; flocculent iron fiber short filament 6%; glass fiber short filament 2%; foam stone particles 8%; kerogen shale particles 22%; hydrophobic perlite particles 48%;

[0042] The particle size of flocculent short iron fiber is 2600 mesh;

[0043] The particle size of glass fiber short filament is 800 mesh;

[0044] The particle size of pumice particles is 40 mesh;

[0045] The particle size of kerogen shale is 40 mesh;

[0046] The particle size of the hydrophobic perlite particles is 30 mesh;

[0047] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com