Environmentally friendly high elasticity sealant and preparation method thereof

A sealant, environmentally friendly technology, applied in the direction of adhesives, adhesive types, non-polymer adhesive additives, etc., can solve the problems of poor elasticity, poor water resistance, insufficient weather resistance and adhesion of polyurethane sealants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

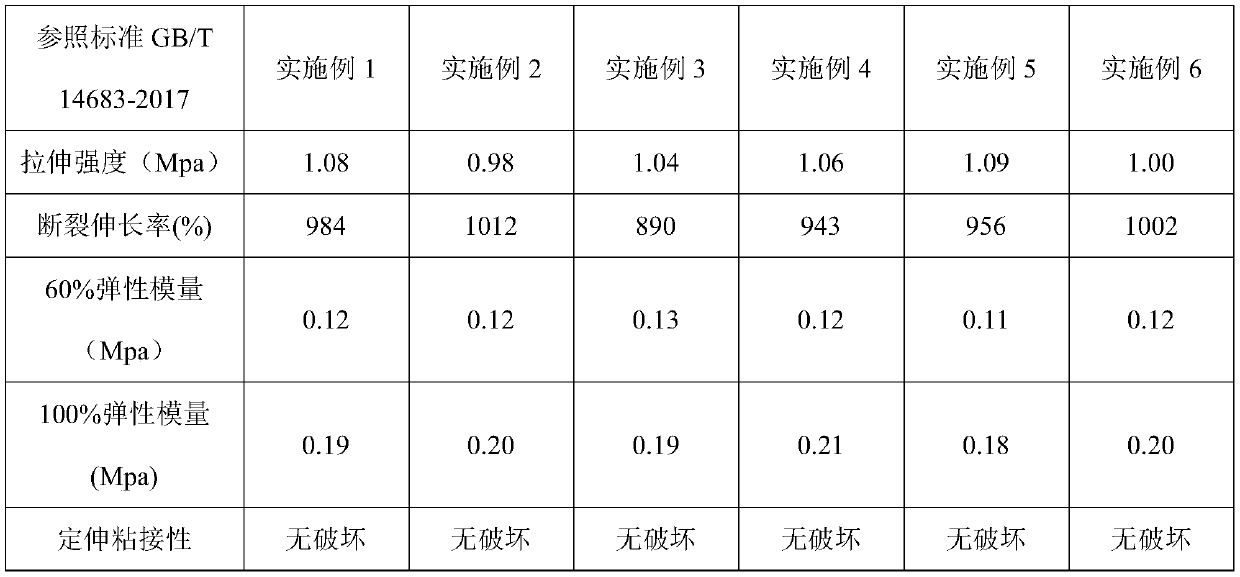

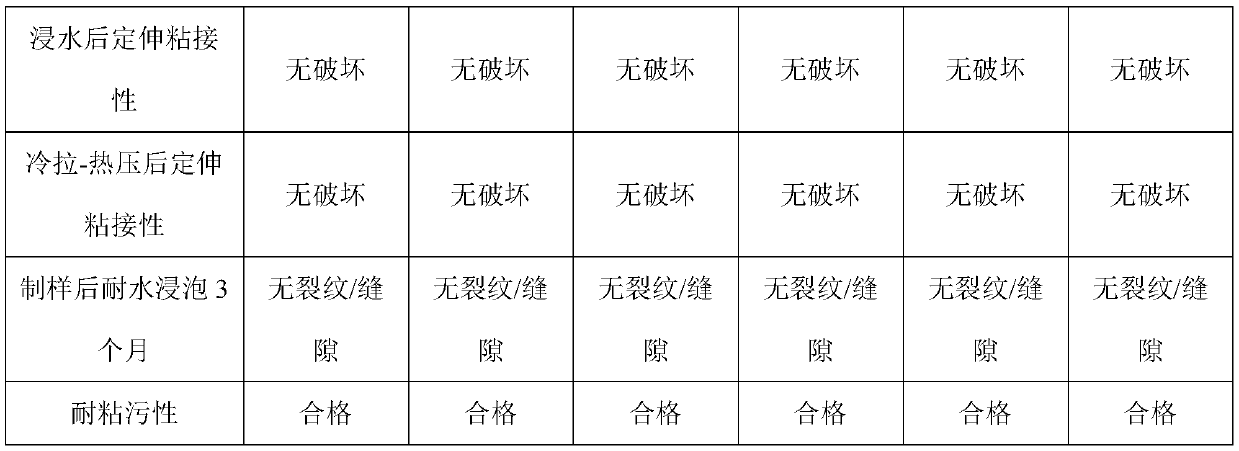

Examples

Embodiment 1

[0022] First, Jinshan Chemical Nano Calcium Carbonate SP-3, ExxonMobil DINP, and Wanhua Chemical Polyether Polyol N220 were dried at 110°C until the moisture content was ≤0.1%. Ether polyol and 22 parts of plasticizer, heat up, start stirring, start adding 40 parts of filler when the temperature rises to 90°C, continue to heat up, heat up to 110-120°C while stirring, keep the temperature and vacuum dehydration, test the moisture of the material ≤0.05%, stop vacuuming, start stirring to cool down, add 12 parts of isocyanate Wanhua MDI50 grade 8683 when the temperature drops to about 50-55°C, then continue to stir and heat up to 80-85°C, vacuumize and pass nitrogen protection reaction 3-4.5h, start to cool down, when the temperature reaches below 50°C, add 25 parts of Wacker Chemie silane-modified polyether XM25, 1.0 part of Xinlantian LT792 silane coupling agent, 1.0 part of moisture scavenger Chenguang CG171, and stir at high speed After 0.5h, the sealant A component can be ob...

Embodiment 2

[0026] First, Jinshan Chemical Nano Calcium Carbonate SP-3, ExxonMobil DINP, and Wanhua Chemical Polyether Polyol N220 were dried at 110°C until their moisture content was ≤0.1%. Ether polyol and 20 parts of plasticizer, heat up, start stirring, start adding 35 parts of filler when the temperature rises to 90°C, continue to heat up, heat up to 110-120°C while stirring, maintain the temperature, vacuum dehydrate, and detect the moisture content of the material When ≤0.05%, stop vacuuming and start stirring to cool down. When the temperature drops to about 50-55°C, add 10 parts of Wanhua Chemical TD180 isocyanate, then continue to stir and heat up to 80-85°C, vacuumize and pass nitrogen protection reaction 3 -4.5h, start to cool down, when the temperature reaches below 50°C, add 22 parts of WACKER E35 silane modified polyether, 1.0 part of LT550 silane coupling agent of New Blue Sky Company, 1.0 part of LT171 moisture scavenger of New Blue Sky Company, Stir for 0.5h, discharge a...

Embodiment 3

[0030]First, Jinshan Chemical Nano Calcium Carbonate SP-3, ExxonMobil DIDP, and Wanhua Chemical Polyether Polyol N330 were dried at 110°C until their moisture content was ≤0.1%. Ether polyol and 20 parts of plasticizer, heat up, start stirring, start adding 35 parts of filler when the temperature rises to 90°C, continue to heat up, heat up to 110-120°C while stirring, maintain the temperature, vacuum dehydrate, and detect the moisture content of the material When ≤0.05%, stop vacuuming and start stirring to cool down. When the temperature drops to about 50-55°C, add 10 parts of Wanhua Chemical TDI80 isocyanate, then continue to stir and heat up to 80-85°C, vacuumize and pass nitrogen protection reaction 3 -4.5h, start to cool down, when the temperature reaches below 50°C, add 22 parts of Zhongyuan Chemical S203H silane-modified polyether, 1.0 part of Momentive Chemical 1120 silane coupling agent, 1.0 part of Chenguang CG171 moisture scavenger, and stir at high speed After 0.5h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com