Photocured prepolymer, preparation method thereof and photocured costume jewelry molding glue prepared from photocured prepolymer

A technology of photocuring prepolymers and polymerization inhibitors, which is applied in the direction of non-polymer organic compound adhesives, adhesives, organic chemistry, etc., can solve the problems of unfavorable environmental protection, low efficiency, long process time, etc., to improve productivity, Good toughness and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

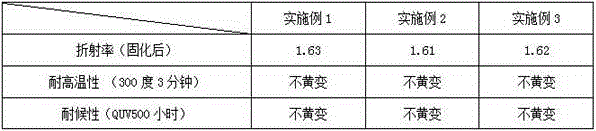

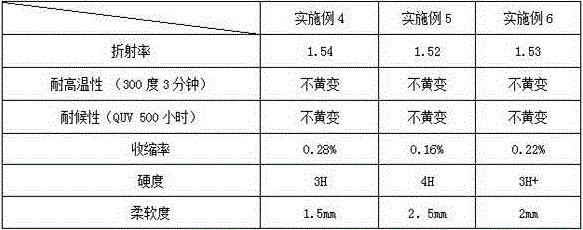

Examples

Embodiment 1

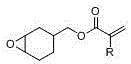

[0037] In parts by weight, add 68 parts of 3,4-epoxycyclohexyl methacrylate and 0.3 parts of 2,5-di-tert-butylhydroquinone into the reaction vessel, heat to 60°C, divide into three times Add 30 parts of dimercaptothiadiazole, pass through cooling water, and control the reaction temperature at 60°C. When the addition of dimercaptothiadiazole is complete, keep the temperature at 60°C for 1 hour. The entire reaction time is 3 hours, and a light yellow product is obtained from the discharge. The yield is 99.6%.

[0038] Its chemical structural formula is as follows:

[0039]

[0040] 1 HNMR (CDCl 3 ,PPM): δ5.83, 6.14, 6.41 H (CH 2 =CH), 4.30, 4.55 CH 2 (CH 2 OCO), 2.03CH(CH-CH 2 -OCO), 2.83 CH(CH-S), 1.38-1.87 CH 2 (on cyclohexyl), 3.84 CH (CH-OH), 4.77 OH.

Embodiment 2

[0042] In parts by weight, 35 parts of dimercaptothiadiazole and 0.5 part of 2,5-di-tert-butylhydroquinone were added to the reaction vessel, heated to 40°C, and 75 parts of 3,4-cycloquinone were added dropwise. Oxycyclohexyl methyl methacrylate, through cooling water, the reaction temperature is controlled at 40°C, when the 3,4-epoxycyclohexyl methyl methacrylate is added dropwise, keep warm at 50°C for 1 hour, the entire reaction time After 5 hours, the light yellow product was obtained by discharging, with a yield of 99.2%.

[0043] Its chemical structural formula is as follows:

[0044]

[0045] 1 HNMR (CDCl 3 ,PPM): δ6.40, 6.48 H (CH 2 =C), 2.01CH 3 (CH 3 CH 2 = CH), 4.30, 4.55 CH 2 (CH 2 OCO), 2.03 CH(CH-CH 2 -OCO), 2.83 CH(CH-S), 1.38-1.87 CH 2 (on cyclohexyl), 3.84 CH (CH-OH), 4.77 OH.

Embodiment 3

[0047]In parts by weight, add 25 parts of dimercaptothiadiazole, 0.2 parts of 2,5-di-tert-butylhydroquinone and 25 parts of isopropanol into the reaction vessel, heat to 70°C, and dropwise add 30 parts of 3,4-epoxycyclohexyl methyl methacrylate and 32 parts of 3,4-epoxycyclohexyl methacrylate, through cooling water, the reaction temperature is controlled at 70 ° C, when 3,4-epoxy cyclohexyl methacrylate After the addition of cyclohexyl methyl methacrylate and 3,4-epoxycyclohexyl methacrylate is completed dropwise, keep the temperature at 70°C for 1 hour, the entire reaction time is 4 hours, heat and distill isopropanol, and discharge the material to obtain Light yellow product, yield 98.9%.

[0048] Its chemical structural formula is as follows:

[0049]

[0050] 1 HNMR (CDCl 3 ,PPM): δ5.83, 6.14, 6.41 H (CH 2 =CH), 6.40, 6.48 H (CH 2 =C) 4.30, 4.55CH 2 (CH 2 OCO), 2.01 CH 3 (CH 3 CH 2 =CH), 2.03 CH(CH-CH 2 -OCO), 2.83 CH(CH-S), 1.38-1.87CH 2 (on cyclohexyl), 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com