Welding method for Q420qENH coating-free weathering steel for steel bridge

A welding method and coating-free technology, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems that hinder the weather-resistant steel bridge from coating, and do not consider the corrosion resistance of the weld, so as to ensure the corrosion resistance , Excellent mechanical properties, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

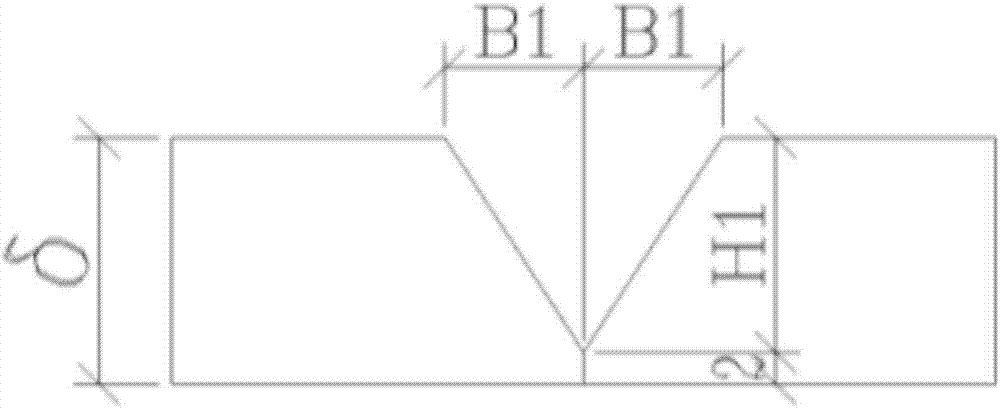

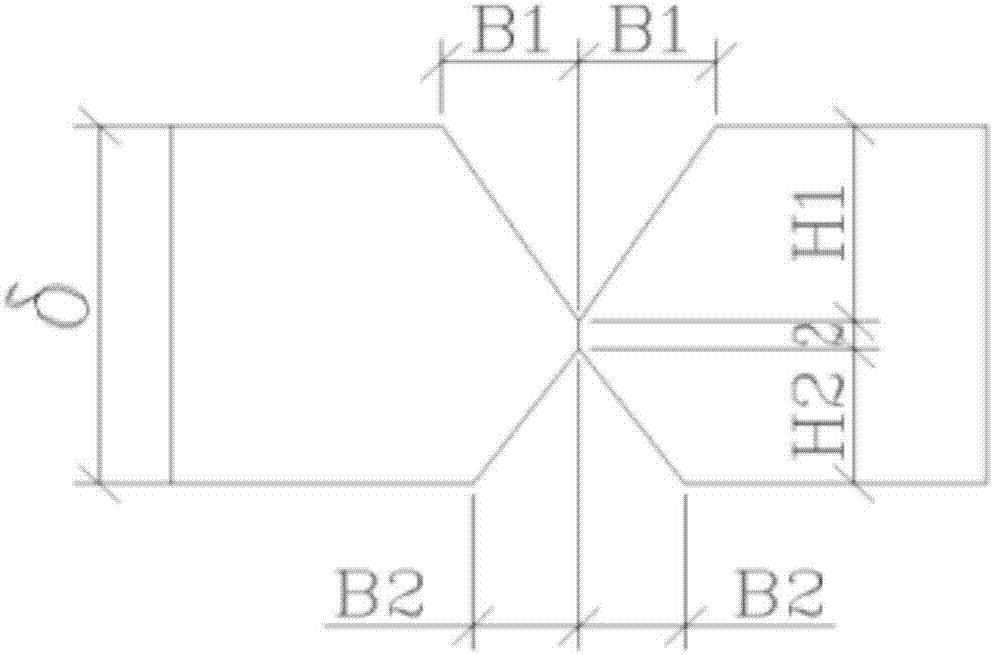

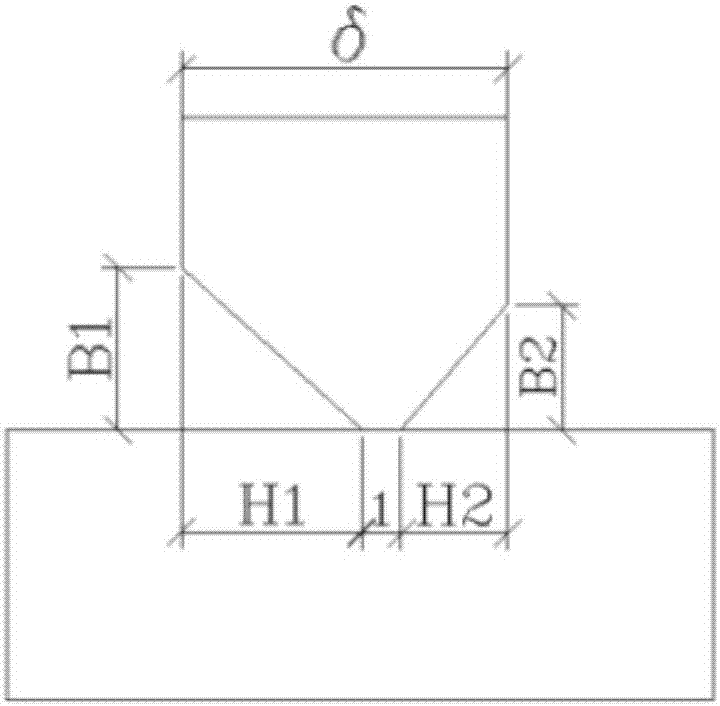

[0029] Attached below Figure 1-4 The present invention will be further described in detail with specific embodiments.

[0030] 1. The chemical composition of Q420qENH coating-free weathering steel used in the specific embodiment of the present invention is listed in the following table according to weight percentage:

[0031]

[0032] Note: In the table, the atmospheric corrosion resistance index of Q420qENH coating-free weathering steel is I≥6.5, and the welding sensitivity index Pcm≤0.23;

[0033] The mechanical properties of the Q420qENH coating-free weathering steel are listed in the following table:

[0034]

[0035] 2. The chemical composition of the welding material used in the specific embodiment of the present invention is listed in the following table according to weight percentage:

[0036]

[0037] Note: The I index of the welding wire in the table is greater than 6.5, and the relative corrosion rate of the deposited metal is ≤8%.

[0038] The mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com