Coating for solar cell back plates

A technology of solar cells and coatings, applied in the field of coatings, can solve the problems of incompatibility of weather resistance and adhesion of fluorine coatings, and achieve the effects of solving the incompatibility of weather resistance and adhesion, simplifying the process, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

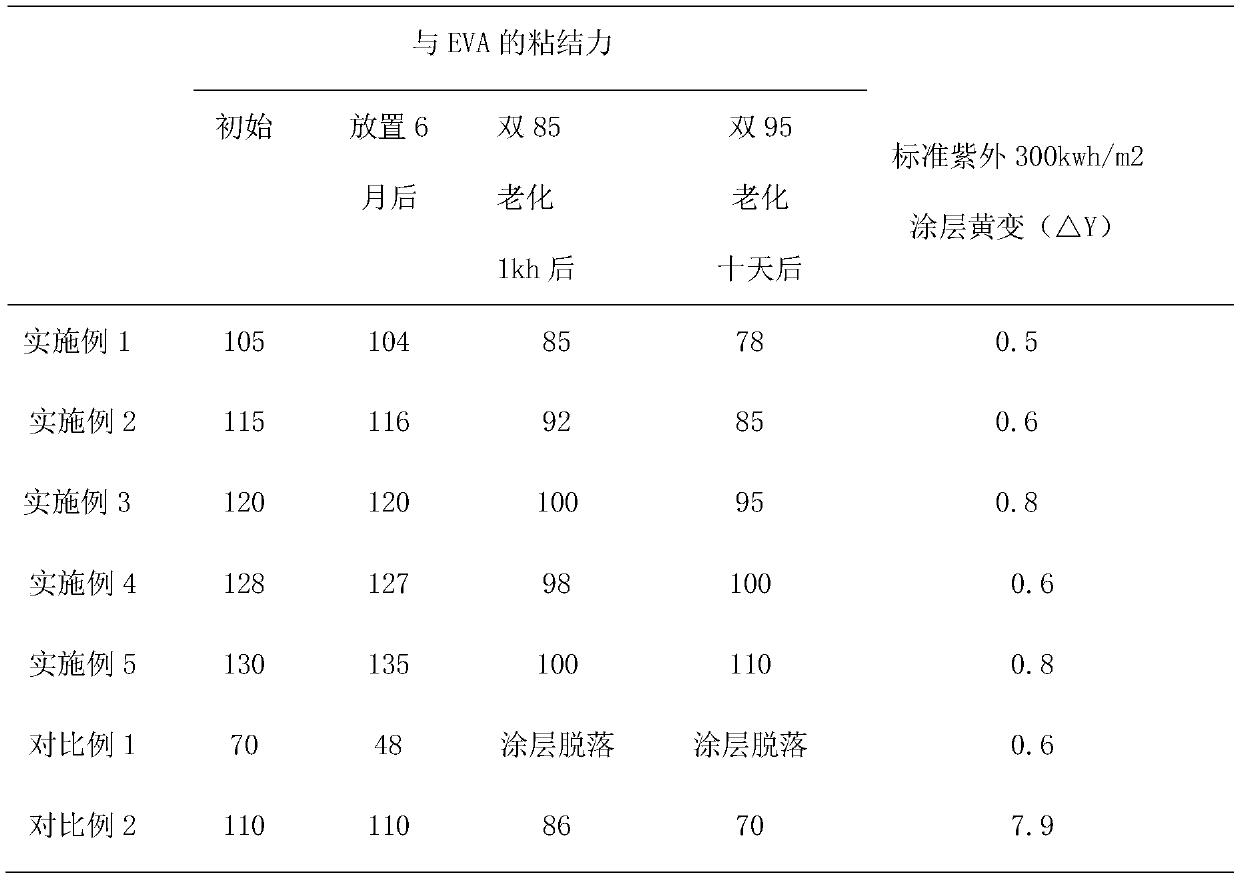

Examples

Embodiment 1

[0028] The synthetic method of acrylic resin: 11.4g methyl acrylate, 81g butyl acrylate, 0.3g hydroxyethyl methacrylate, 4.3g glycidyl methacrylate, 100g toluene, add to a cooling tube, stirring device, thermometer nitrogen Into the four-necked flask with the introduction tube, add 0.08 g of the initiator azobisisobutyronitrile to react for 6 hours. Then add 0.03g of hydroquinone, 0.8g of dimethylbenzylamine, and 2.2g of acrylic acid, and stir at 100°C for 15h until the acid value is as low as 0.1mgKOH / g. Finally obtain acrylic resin with hydroxyl and double bonds, wherein the molar ratio of side chains containing carbon-carbon double bonds in the resin segment to the total side chains is 0.03, the hydroxyl value is 1mgKOH / g, the molecular weight of acrylic resin is 6000, and the solid content is 50 % acrylic resin solution.

[0029] Fluorocarbon coating for solar backplane, consisting of 22g GK570 solution, 7.3g of the above-mentioned acrylic resin solution, 21.7g of titaniu...

Embodiment 2

[0032] The preparation method of acrylic resin: 15.4g methyl acrylate, 76.8g butyl acrylate, 2.7g hydroxyethyl acrylate, 2.8g glycidyl methacrylate, 100g toluene, add to the tank with cooling tube, stirring device, thermometer nitrogen introduction Into the four-neck flask of the tube, add initiator azobisisobutyronitrile 0.08g to react for 4h. Then add 0.03 g of hydroquinone, 0.8 g of dimethylbenzylamine, and 1.5 g of acrylic acid, and stir at 100° C. for 15 h. Finally obtain acrylic resin with hydroxyl and double bonds, wherein the molar ratio of side chains containing carbon-carbon double bonds in the resin segment to the total side chains is 0.02, the hydroxyl value is 13 mg KOH / g, the molecular weight of acrylic resin is 9000, and the solid content is 50 % acrylic resin solution.

[0033]Fluorocarbon coatings for solar back panels, consisting of 24g Changxing 41011 resin solution, 7.2g of the above-mentioned acrylic resin solution, 22.5g of titanium dioxide R706, 0.1g of...

Embodiment 3

[0036] Preparation of acrylic resin: 12.7g methyl methacrylate, 79.2g butyl methacrylate, 5.8g hydroxypropyl acrylate, 1.5g glycidyl methacrylate, 100g toluene, add to a cooling tube, stirring device, Azobisisobutyronitrile was added into a four-necked flask with a nitrogen introduction tube for a thermometer to react for 4 hours. Then add 0.03g of hydroquinone, 0.8g of dimethylbenzylamine, and 0.8g of acrylic acid, stir at 100°C for 15h, and finally obtain an acrylic resin with hydroxyl and double bonds. The molar ratio of side chains containing carbon-carbon double bonds in the total side chains in the resin segment is 0.02, the hydroxyl value is 20 mg KOH / g, the molecular weight of the acrylic resin is 12000, and the acrylic resin solution has a solid content of 50%.

[0037] Fluorocarbon coating for solar backplane, consisting of 19g of GK570 solution, 8.2g of the above-mentioned acrylic resin solution, 20.5 of titanium dioxide R706, 0.4g of leveling agent BYK310, 0.4g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com